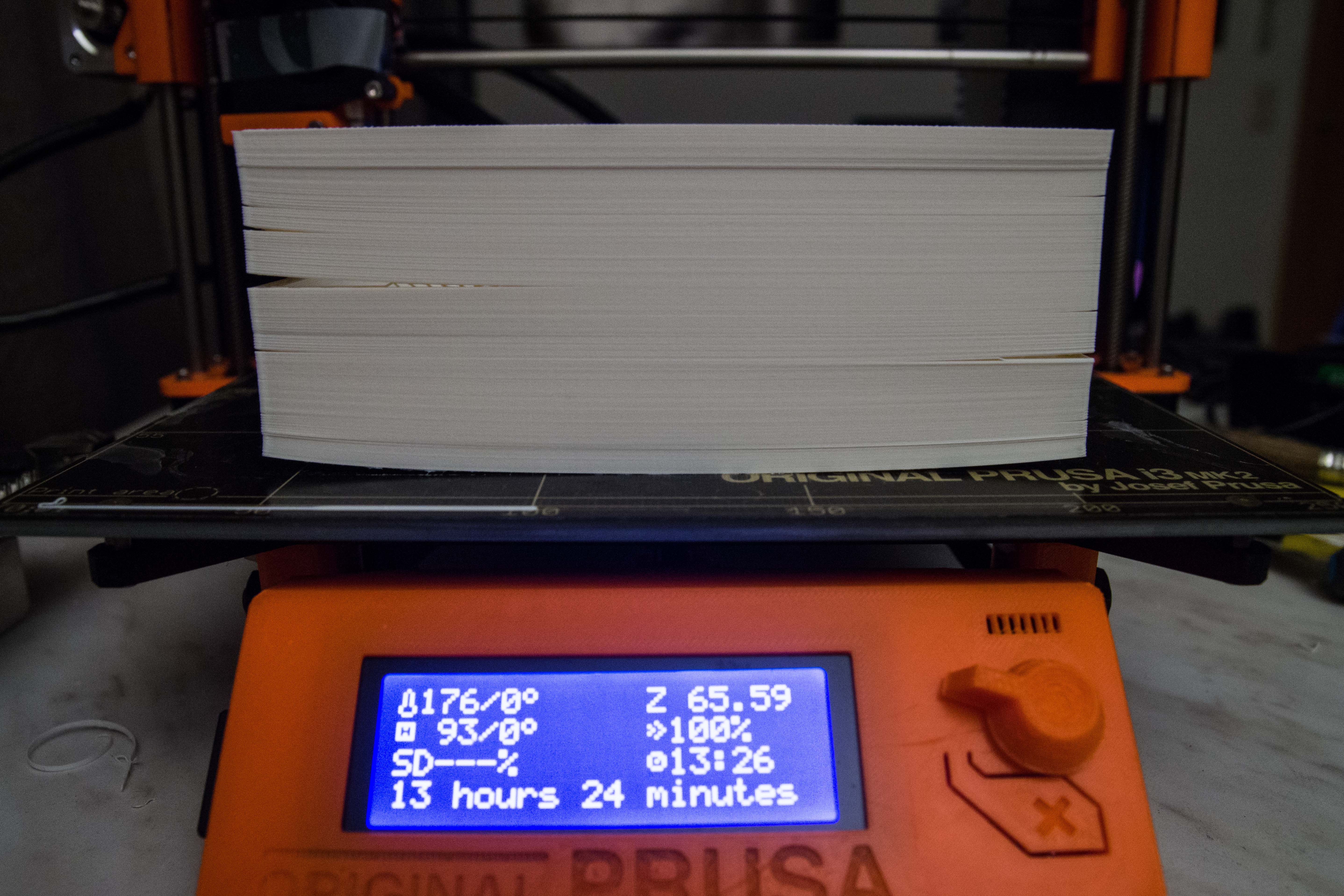

This weekend I finalize the Standing Controller box 3D printing from Danny. I love the design and he demonstrated a lot of creativity. This print took 13h26 min.

But my 3D printer and ABS plastic had a lot of warping issues.I will look out for other ABS plastic that may have less warping issues. Or maybe next time I just use PLA instead.

It started like it would print normally. I took special precautious to

make it was extra sticky to the heat bed by pouring a bit of acetone on it

and then scrub it with leftover ABS. That plastic melted on the heat-bed and

created a better sticking layer.

The first 5 mm went perfect with solid sticking on the bed. But as the print grew it actually started to pull the plastic from the heat-bed. And the fact that I also have splits in the layers in between means that I probably need a temperature controlled enclosure.

I can also repair the holes with some pasture or ABS hiding.

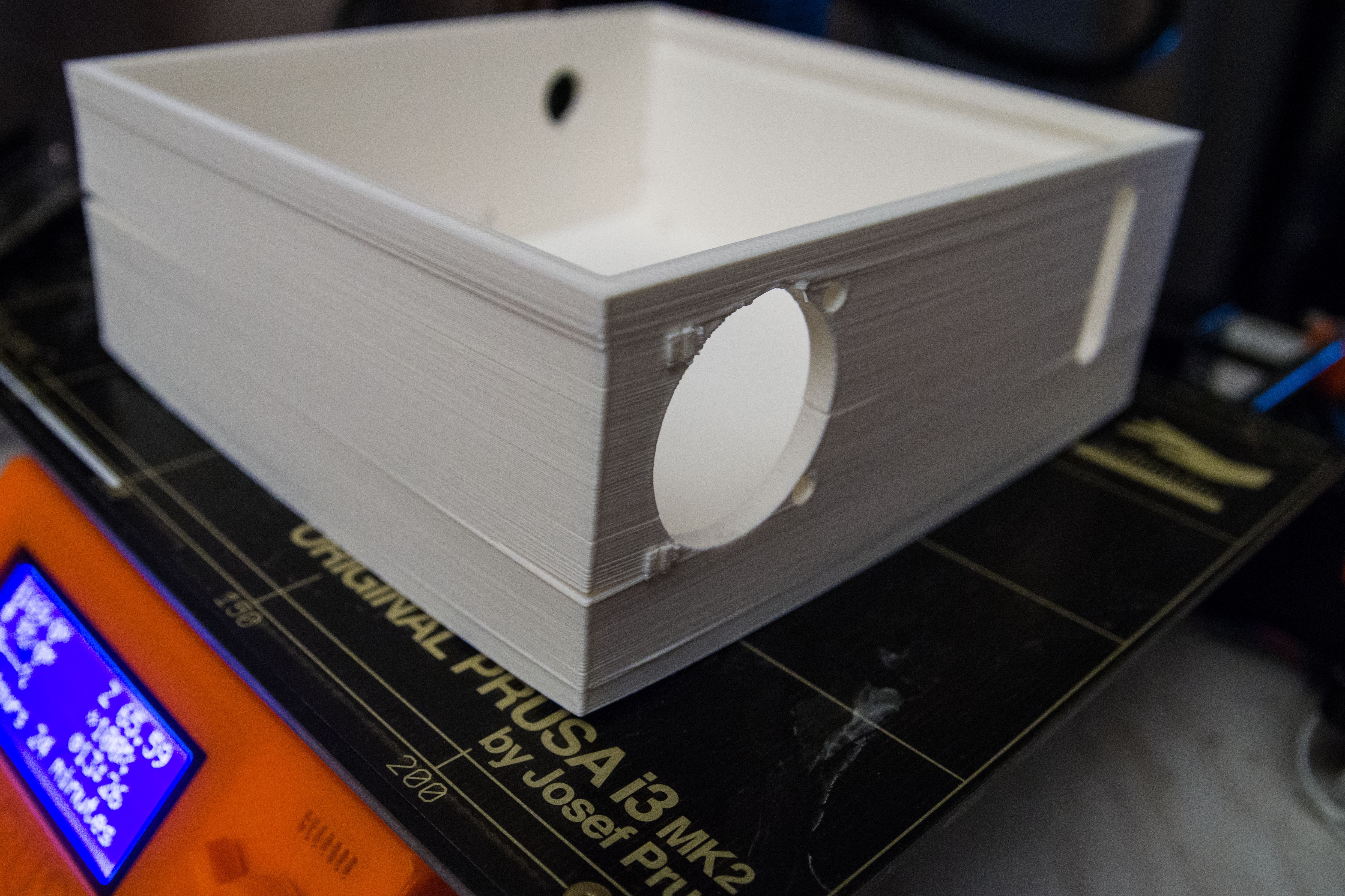

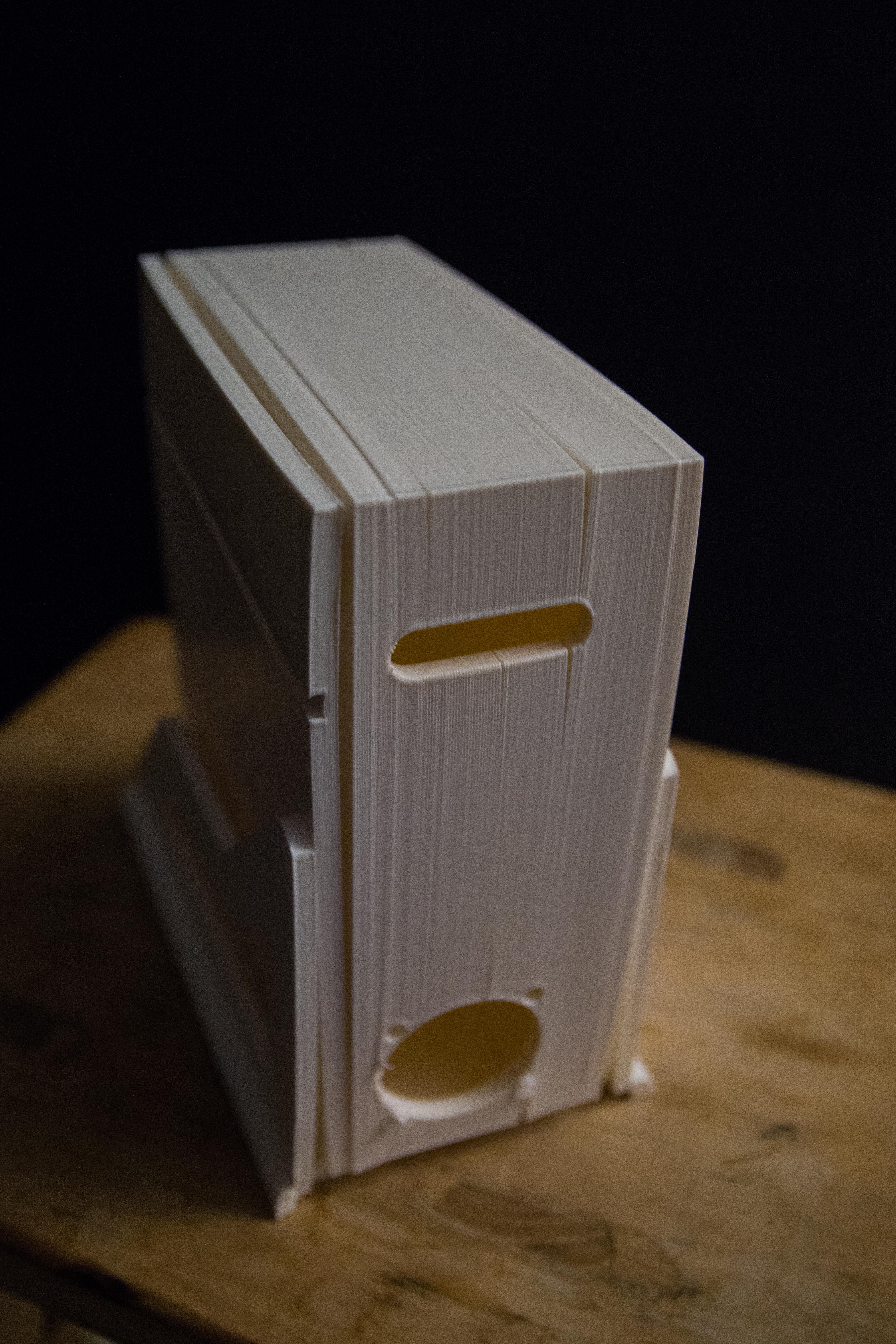

Side view to show the ventilator hole

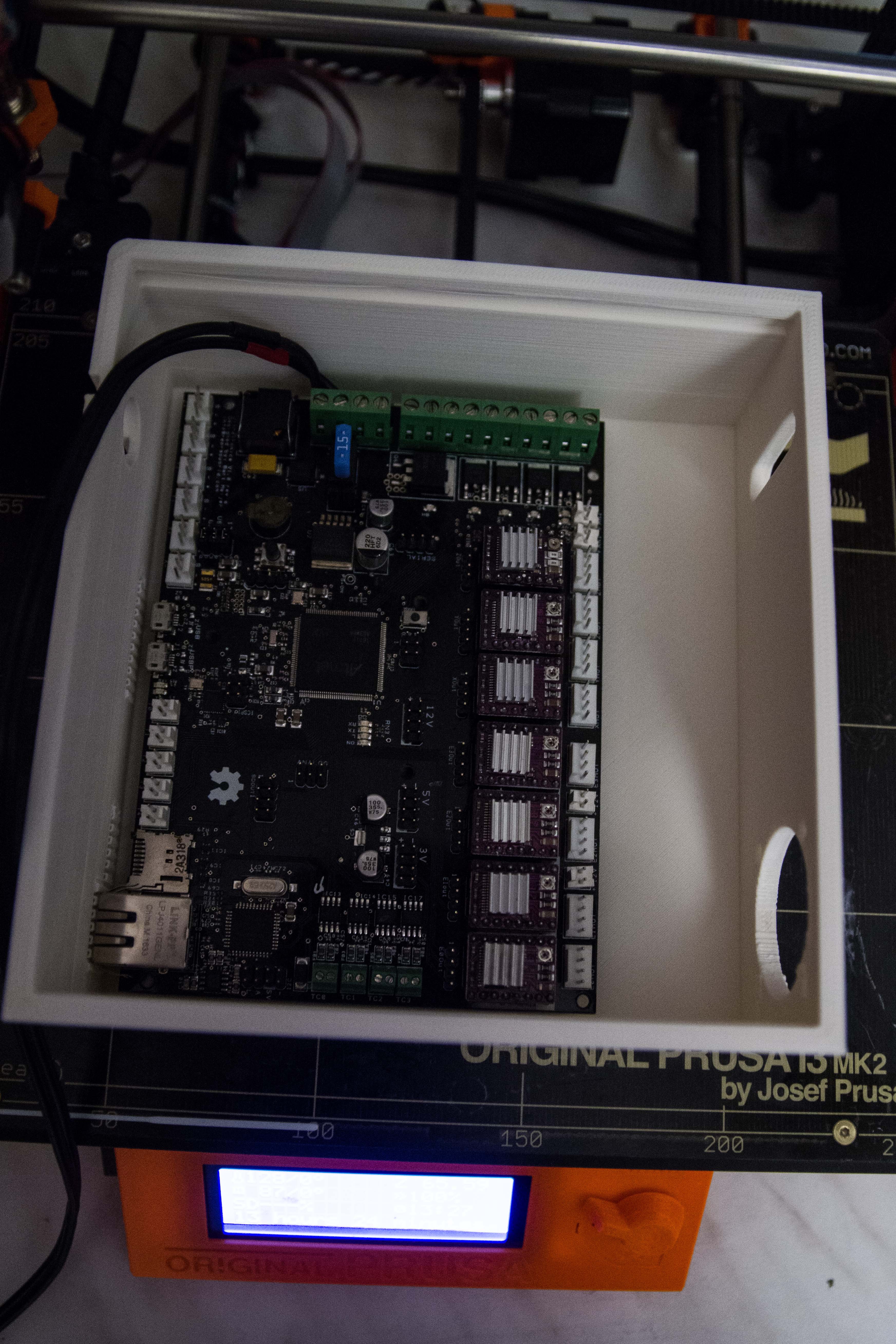

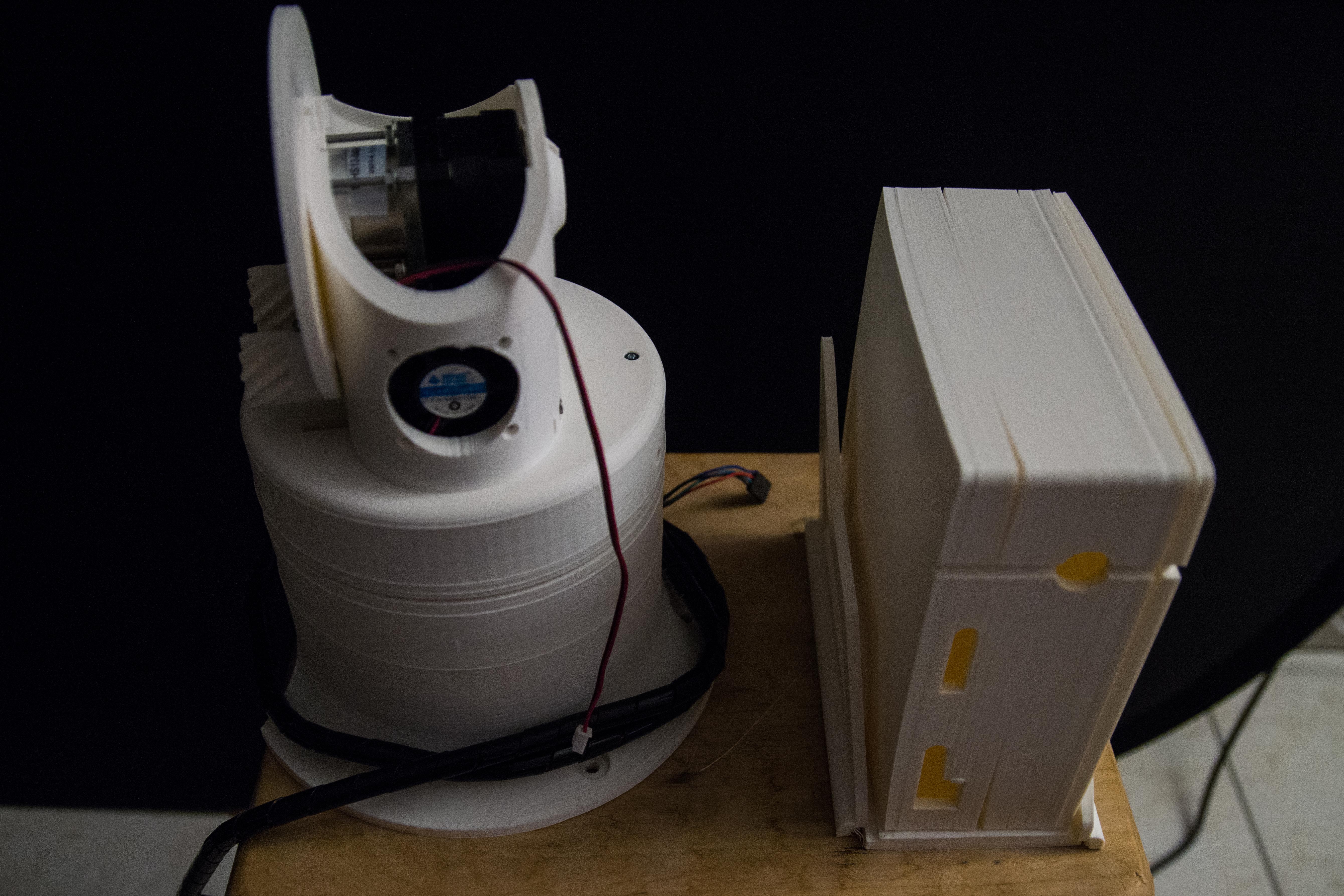

Top view with the Ultratronic v1.0 pro board inserted to see if it did fit. It appears that the box will be just right.

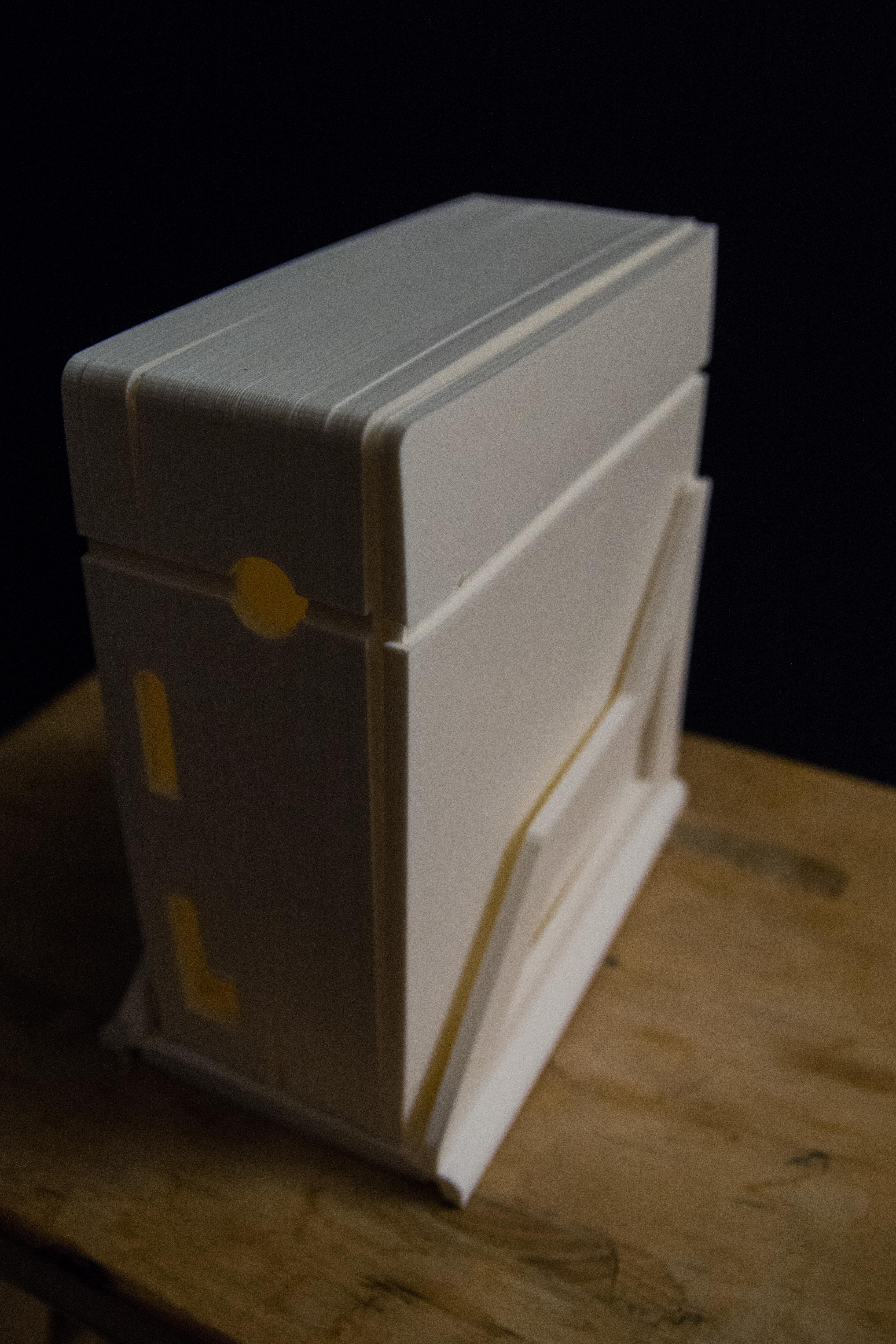

Partially assembled with the parts I printed last week. Missing in this view are these cool strips that can be colored differently and then inserted into the groves.

The lid on the right, I printed yesterday and was a 7 hour job. It also had warping issues.

Back view showing the ventilator hole.

I am wondering if the box will be better upside down. I probably want to blow the heat outside the box. But in that case the ventilator needs to be at the top.

Scale comparison with the Thor robot base.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I think I will have to get some nice paint to color Thor soon.

Are you sure? yes | no