I went through a range of tire aspect ratios and rim widths and watched the resulting angle which is required for the filament holes. All the ones that make sense are between 2-7 degrees of being 90 degrees from the tangent to the rim around the circumference. That means I could eliminate needing a CW and a CCW version and just have one.

The filament holes still need to be outwardly angled to generate a tire width wider than the rim, but the lower tire aspect ratios also usually correspond to the use of a wider rim. This means for the vast majority, that angle ends up just pointing at the centerline for the rotational axis of the rim.

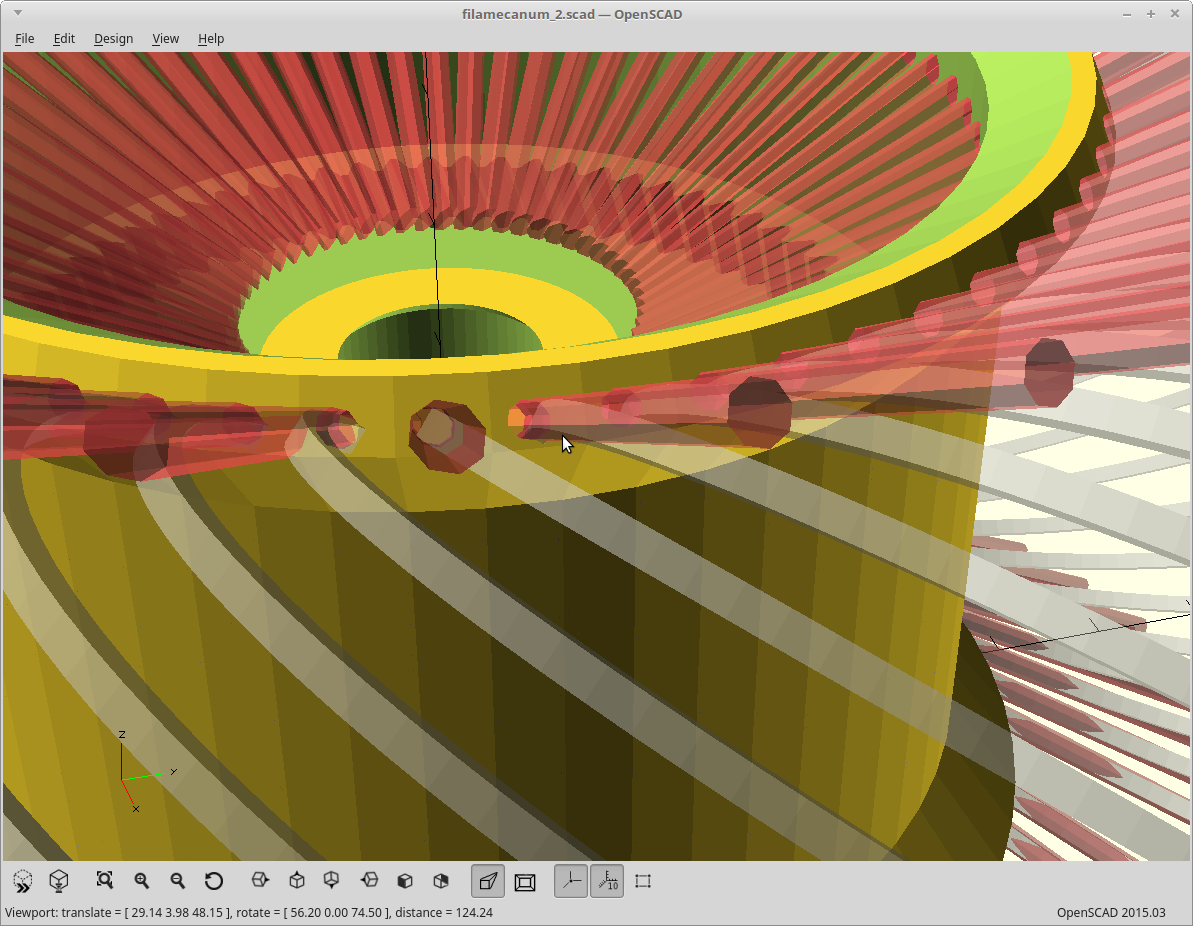

Those two points mean I can simplify the modeling of the filament holes significantly here and generate a single parametric model. I'm starting over with a fresh model, and doing that.

I'm going to split the rim and hub back up as well. It will consume less material to print this as two parts as then I don't need the conical underside to keep the overhangs manageable. Using a narrow rim aspect ratio would not have worked before as the overhang required for the cone became too severe. Now both parts can be optimized for what they need to do, and be parametric. It also means the transmission can go back to being laser cut. The only sticking point here is then I should really put the surface for the motor end seal in the transmission model, which means the output ring will end up needing a small rim as well.

Daren Schwenke

Daren Schwenke

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.