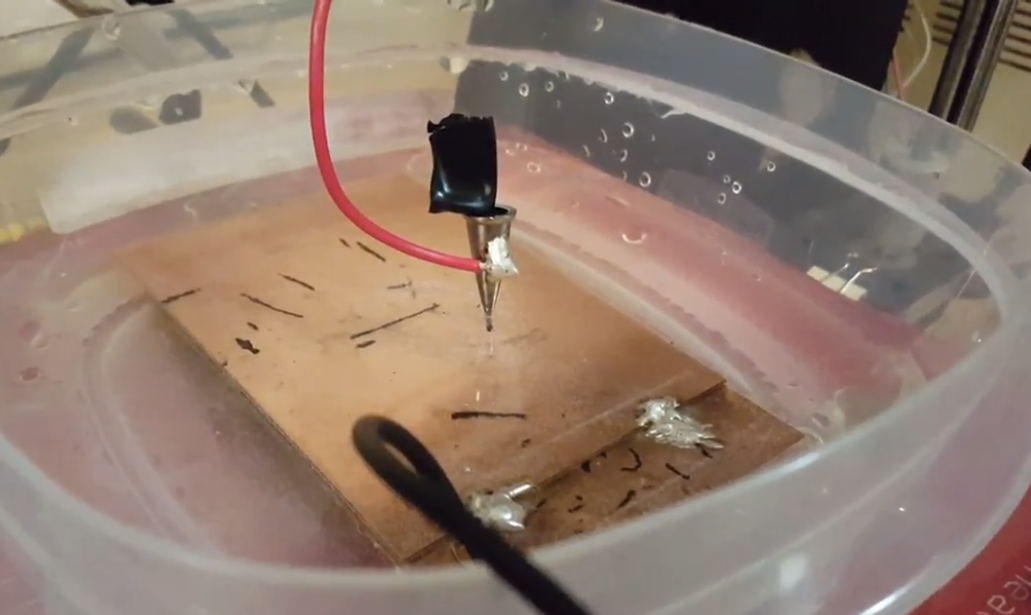

It is really easy to cut PCBs by hand. Simply alligator clip a blank PCB with the low voltage side of the power supply, hold pencil lead with the high voltage (30V, 3A current limited) alligator clip and softly pull the lead tip along the surface. But that isn't useful. We want to have a CNC machine that will do it for us.

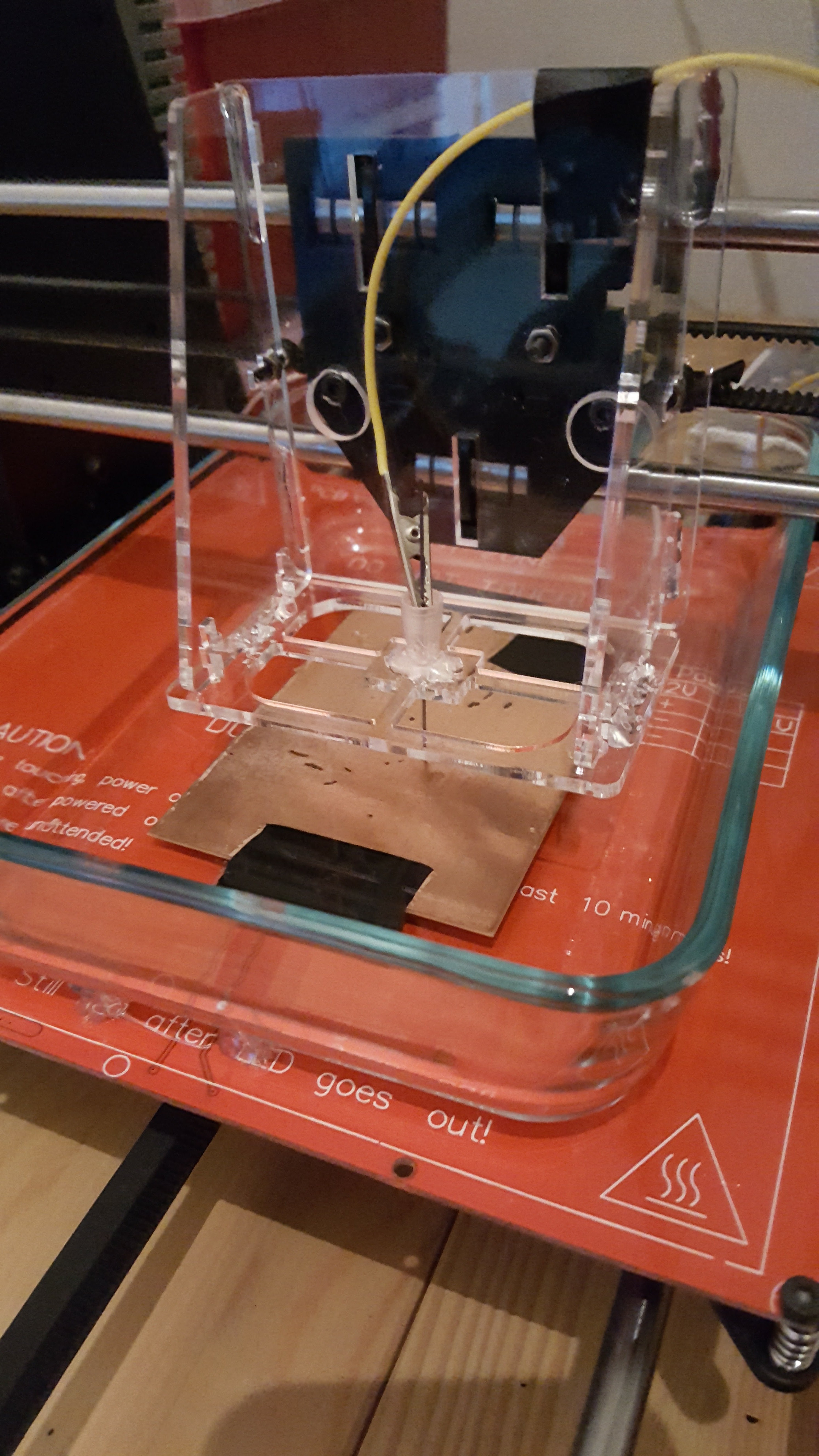

We had a 3D-printer sitting around not 3D-printing that was the perfect CNC base to test out ideas. We quickly recognized that a soft touch is critical, so we hacked together a "spring" made of solid core wire soldered to the tip of a mechanical pencil, as seen below. As it turns out, we got the first CNC cuts with this setup, but it was unsurprisingly unreliable, and only cut well in one direction. Nonetheless, it was an awesome quick proof of concept.

A while later, we made a more robust mounting setup using laser cut acrylic. It is still janky, with the pencil lead guided through a mechanical pencil tip hot glued to the support, and power coming from an alligator clip. Nonetheless, it was much more reliable and consistent. The lead is able to slide somewhat within the pencil tip, which allows some flexibility in the system needed to cut.

The first full shape we cut was a sort-of dogbone. On one end, the separation was designed for an 0805 SMD package. Interestingly, the cut width is actually usually smaller than the diameter of the graphite used, and the edges on the cuts here are pretty smooth and consistent. The hardest part here is dealing with the graphite consumption and warped PCB.

Finally, some video of the cutting process. The cutting is pretty fast, but obviously there are sections where it pulls away from contact and stops cutting.

Finally, some video of the cutting process. The cutting is pretty fast, but obviously there are sections where it pulls away from contact and stops cutting.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.