I used to had a grandmother. I remember her as a lovely person. She always tried her best to take care of me and my brother. Every time we went to visit her she was trying her best to take care of us. She was cooking for us, trying to play a board game or football. It took me years to realise that with time she is getting weaker and walking is becoming more and more difficult for her. Simple things like standing up, walking stairs or opening door become more and more challenging. At the time, I was unable to anything with that, however that inspired me to do something with that and I create a device which will be helpful for the older people and for the people with physical disabilities.

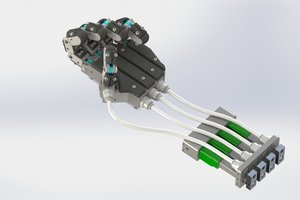

I am unable to create artificial limbs or exoskeleton, so I decided to design something more realistic and more affordable. I would like to introduce the concept of the intelligent indoor door system. That device will provide great help with home door management and will make it possible to remotely open/close doors without the need to push/pull them or to use any handles.

In the future system can be potentially further develop in a way to provide more features, which can bring additional help for the society such as the anti-burglary system (automatic closing of the door if a burglary was detected and no one is at home), invocation/prevention of drafts (in order to ventilate the house, lower the temperature).

Paczkaexpress

Paczkaexpress

Joseph Prosnitz

Joseph Prosnitz

Anthony Tamalonis

Anthony Tamalonis

Mei-Li Hey

Mei-Li Hey