BigFDM

Open Source Large Scale 3D Printer

Premises

We dream in a future of freedom, where open source hardware and Fab Labs enable people to fully understand how to make things they need, and where decentralized local production is customized to impact the surrounding community. Believing that empowering the user with knowledge about how to make machines, BigFDM wants to give to the world a powerful open source tool, to 3D print any large scale object you may need. And, together with LaserDuo, this is one of the first steps in developing other machines sharing the same philosophy.

BigFDM

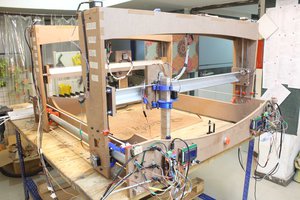

BigFDM is an open source large scale 3D printer.

Taking advantage of what we have learned in Fab Academy, BigFDM has been developed using standard Fab Lab equipment and techniques. BigFDM was in fact built in Fab Lab UAE by Daniele Ingrassia with the help of Hashim Al Sakkaf. Reversing the consumer process, where knowledge and building of machines stays inside a black box managed by companies, BigFDM brings the advantages of an open source development:

- full awareness about how the machine works

- reproducible design

- possibility to customize the machine and/or to build new ones

- built as much as possible with local materials

- local self-fixing and self-production of the machine parts

- community can use and improve the design

- cheap alternative to large scale 3D printers

- use BigFDM as tool to produce other open source machines

BigFDM allows the printing of large scale objects, some examples can be orthotics and prosthesis, art installations, furniture, replacement parts, industrial design prototypes, molds for casting of full scale parts. Using Fused Deposition Modeling (or FDM), it can use standard 2.85mm 3D printer filament, and as well common extruders nozzles.

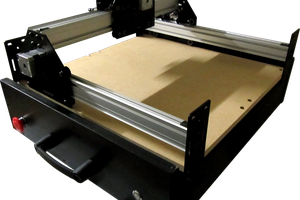

BigFDM specifications:

- 800mm x 800mm x 900mm printing area

- dual extruder with interchangeble nozzle

- 2.85mm filament

- 0.4 - 1mm nozzle size

- NEMA 24/23 stepper motors

- stages with HiWin linear guides

- anodized aluminium frame

- heated bed with 4 x 750W bed heaters

- closed housing of aluminum composite and acrylic

- fabbable satshakit and satstep based electronics

- integrated tablet for machine control

- printing from USB drive

- BOM cost of about 2600€

- power requirements 220V, 3000W max

Machine design

BigFDM has been designed considering to keep fixed from the beginning few constraints, which then influenced the rest of the subsequent design choices:

- the all machine parts must be inside a boxed main frame

- the machine XY stages design must be independent and consistent by itself

- the Z axis moves the bed up or down

These have been tought in order to bring the following benefits:

- a compact design that maximize the printing area while minizing the unused space (just 2mm between the bed supports and the housing!)

- minimizing the unused space has lowered the cost of the frame and the housing parts

- the main frame serves both as structural squared reference for all the machine parts and well as body for the housing

- the XY stages can be completely removed without disassembling any other machine section

- the XY stage indipendent design can be reused to develop other machines

- the machine printing area can be scaled up/down just by changing the length of few machine parts

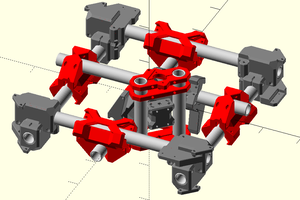

X and Y stages

The X and Y stages integrates all their components inside a squared plane frame of T-Slots profiles. Hiwin 15mm linear guides and 10mm GT2 belts, together with custom CNC milled POM parts have been used. Implementing a sort of stages interoperability, the stages frame can be completely detached from the machine, and virtually, plugged into a different machine having similar frame shape (eg a laser cutter). Similar interoperability has also been recursively kept for the Y axis, which can be modified/removed without changing the X axis.

Z axis

The Z axis uses a single NEMA 24 to move 4 lead screws guided by 4 linear rods and bearings. A 4.7m closed loop HTD M3 belt...

Read more » Daniele Ingrassia

Daniele Ingrassia

Sam Griffen

Sam Griffen

Nishant Agarwal

Nishant Agarwal

Alex

Alex