Working on soft multithreading software to let step motors work simultaniously. Vanish graphical display, ways to sloooow to work with, takes to many resources. Googled the web and find cheap displays 'Nextion' with building cpu and with seperate graphical designer. Very little resources with simple serial communication. Gone try this one. Not at the end of my story for now :)

dannyvandenheuvel

dannyvandenheuvel

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I have some questions about the Pololu DRV8825 current resistor is set to 0.1 Ohm, so according to the

DRV8825 documentation the Vref = [motor current limit] /2. My stepper motor draw 0.4 A so that Vref = 0.2V

But the Ultratronics v1.0 has for the Z-motor 2 connectors, and the Thor robot also has 2 motors that must work as one motor. Each has 0.4A to draw, does that mean that I have to set this DRV8825 VRef to 2X0.4 A = .8A ==> Vref 0.4V?

It is unclear for me if the 2 motors will not have issues when one draws more current than the other one and this translates to asymmetrical mechanical driving issues that causes wear on the cogs?

I could of course drive the 2 stepper motors separately but again I end up with a stepper issue because one motor will get one step advance ahead before the other one. This again causes stress on the cogs.

Are you sure? yes | no

I am going to test what will be the best,

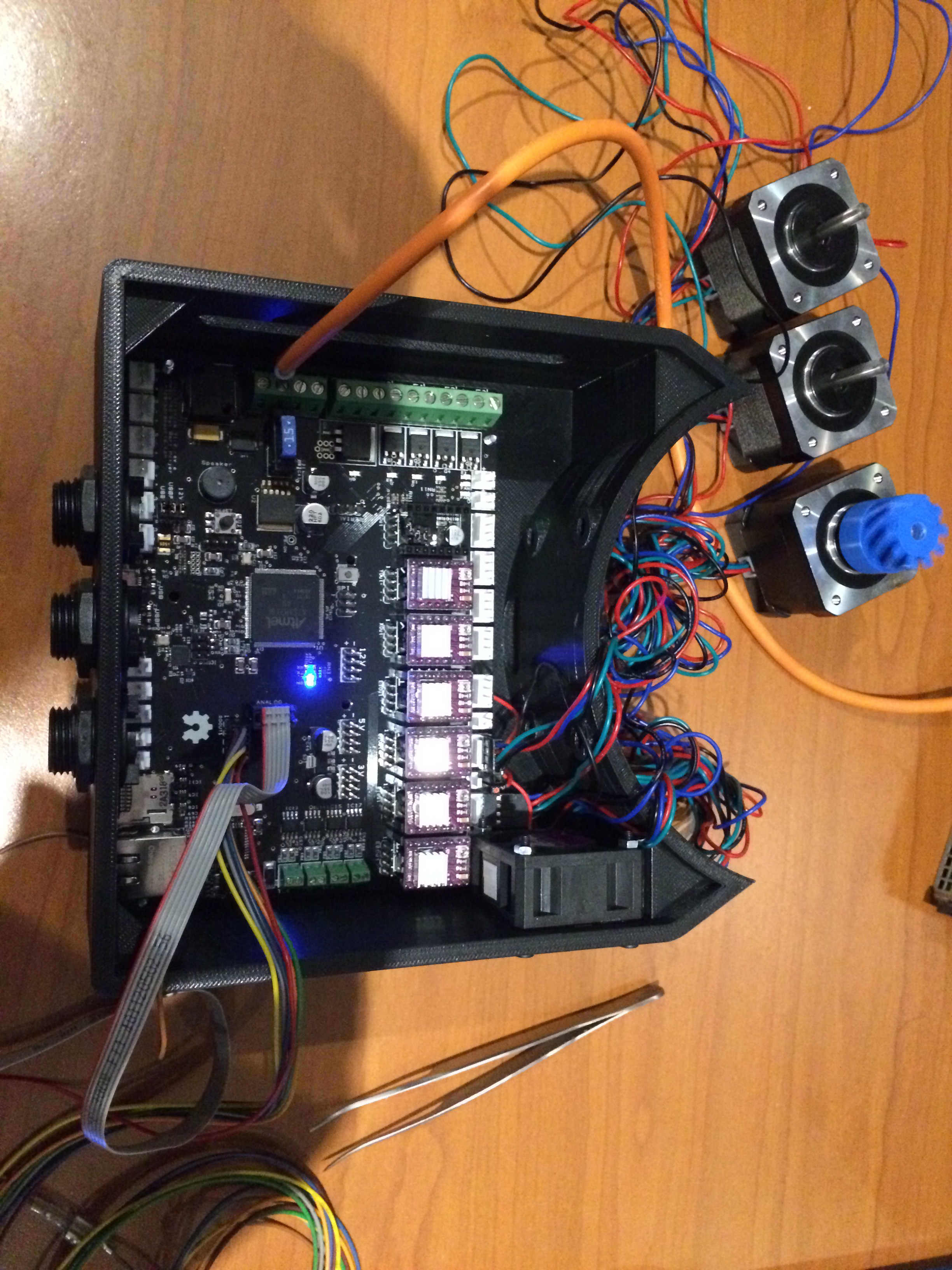

One stepper driver for each motor, we have 6 stepper motors. The counting starts from the left side to the right. E0,E1,E2,E3,X,Y & Z. I am going to use E0=base, E1 and E2= rotation arm1, E3= rotation arm2, X,Y=rotation wrist or moving tool up,down. For the gripper I going to use a servo motor and take a free PWM output. For the neopixel light at the gripper a use a second PWM output.

I think for E1,E2 there will be no problem because there's a gearing 1:5.

If this is giving to much stress I going the bring the motors togetter on one driver like you mentioned

I'll have to test it!

Are you sure? yes | no

Hello Danny, I also am receiving my components. I am following your advice. :-)

But I have a question. The Sunpower power source has 24V/4 A. This main board can control up to 7 RAMPS and provide 7 A.

Now comes the question, if software is developed to power all 6 Thor motors at once for speed. Don't we end up in having not enough power? Will de software need some consumed power detection to reduce the motor speeds?

Are you sure? yes | no

5 motors 0.4Ax24V= 9.60Wx5 = 48W

1 motor 2Ax24V=48W

Total comsumpsion = 96W / 24V = 4Amp when all motors use full power.

This will not hapen because rotating base will only be moved when object has been picked up.

Overall power will be between 2 and 3 Amps.

Are you sure? yes | no

Also 3 motors are geared and will be 1:5 so factor 5 more power

Are you sure? yes | no

Makes sense :-)

I just received my 17HS13-0404S-PG5 planetary gear motors but discovered that it is very hard to get into the motor house.

When I try to get the motors inside, I also pretty fast realize that it is going to be very hot inside! 3 planetary motors and a plastic that does not conduct heat.

Are you sure? yes | no

Olaf, that's why I made the last modification with the holes for fans and air flow :/

Are you sure? yes | no

Am I correct that the motherboard does not come with these Step motor controllers?

Are you sure? yes | no

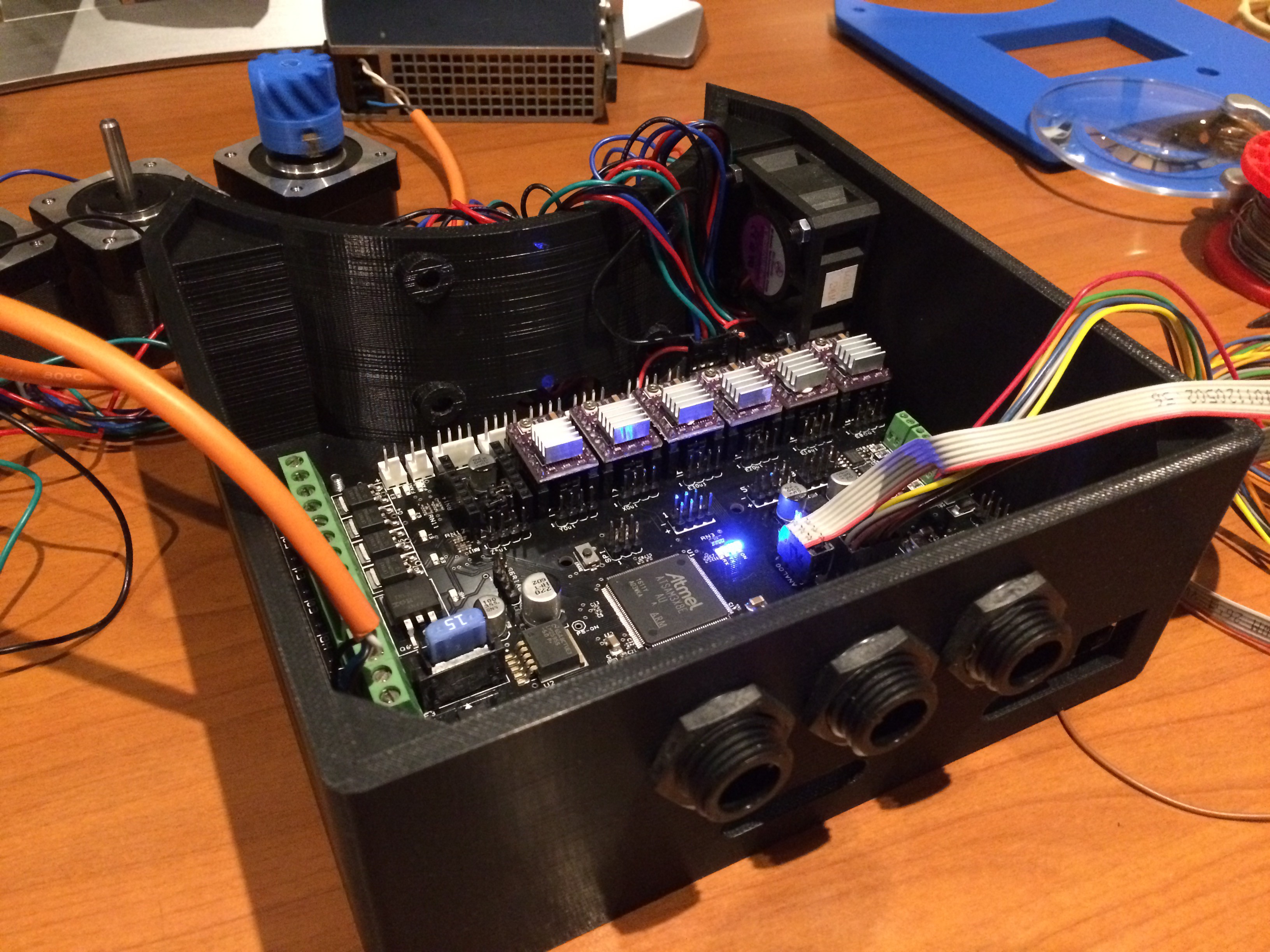

The reason working with a motherboard with all onboard is to avoid all the interferences that will hapen on the pwm signals, my first project I had a lot of problems with it. The controllers on board is a good thing in that way. Also the wires to the motors and all the homing switches, the seperate pwm servo for the gripper and the neopixel light on top of it. Now I can bundle everything nicely togetter. Only the power supply but that fine, never build a power supply into this environment, weird things could happen :)

You can order everything at https://www.123-3d.nl/ or https://reprapworld.nl , the display will be from https://www.itead.cc/wiki/Nextion_HMI_Solution, next week the hardware will be build and I will inform everything on my page.

Are you sure? yes | no

Interference, makes sense.

Are you sure? yes | no

I just ordered that same controller :-)

Your explanation makes sense, and even though I already have a controller, it is going to cost me more to find the components, sockets,..... and risk ending up with a none functional controller because of interference.

Are you sure? yes | no

WOW!

Are you sure? yes | no