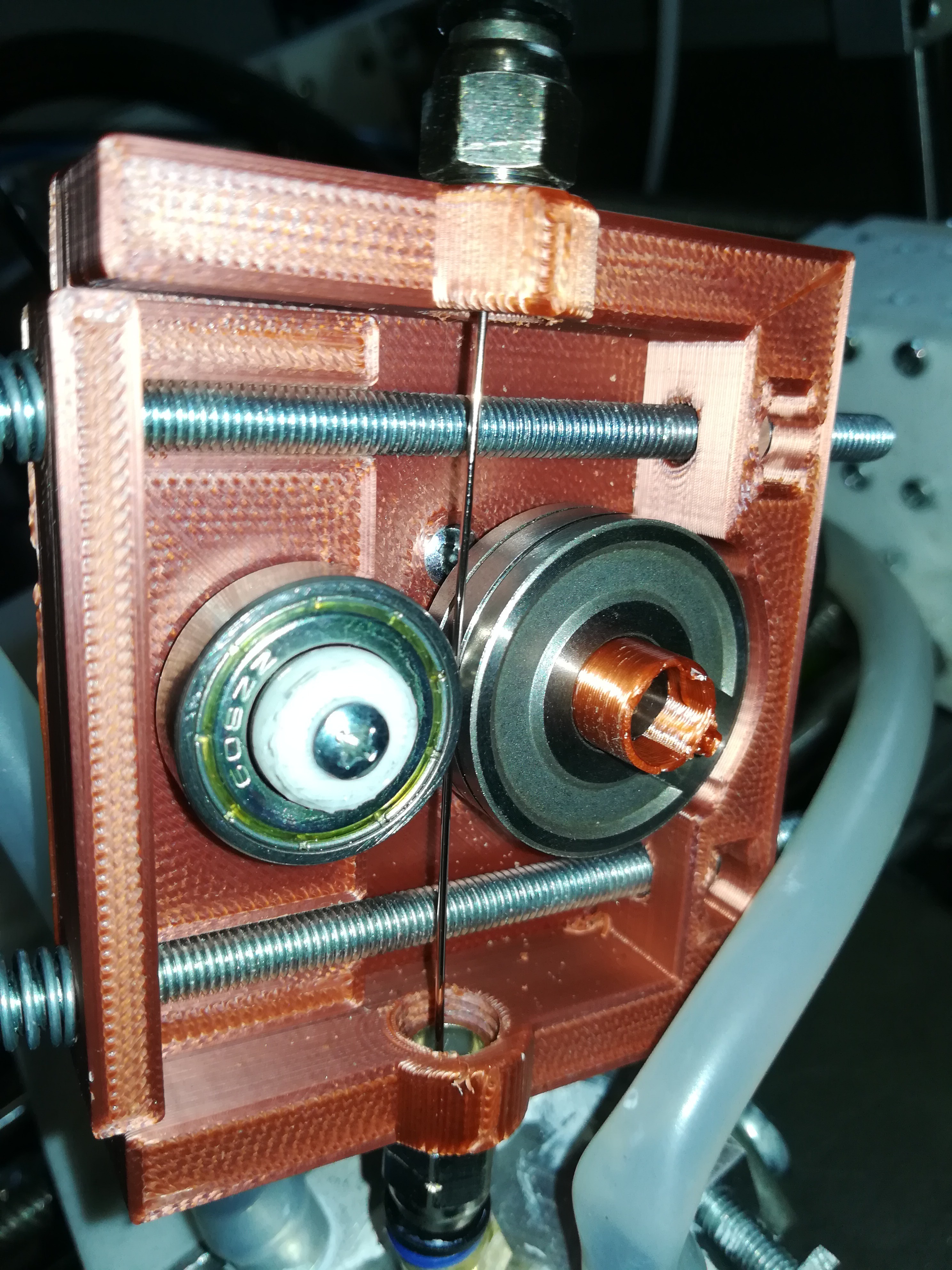

To give the wire feeder more torque I replaced the normal Nema 17 stepper with a geared 14:1 nema 17 stepper.

I also replaced the feeder wheel with a larger one in which the motor shaft fits.

With the new feeder, there should be no more lost steps due to the motor torque.

I could also print a better fused together thing with it.

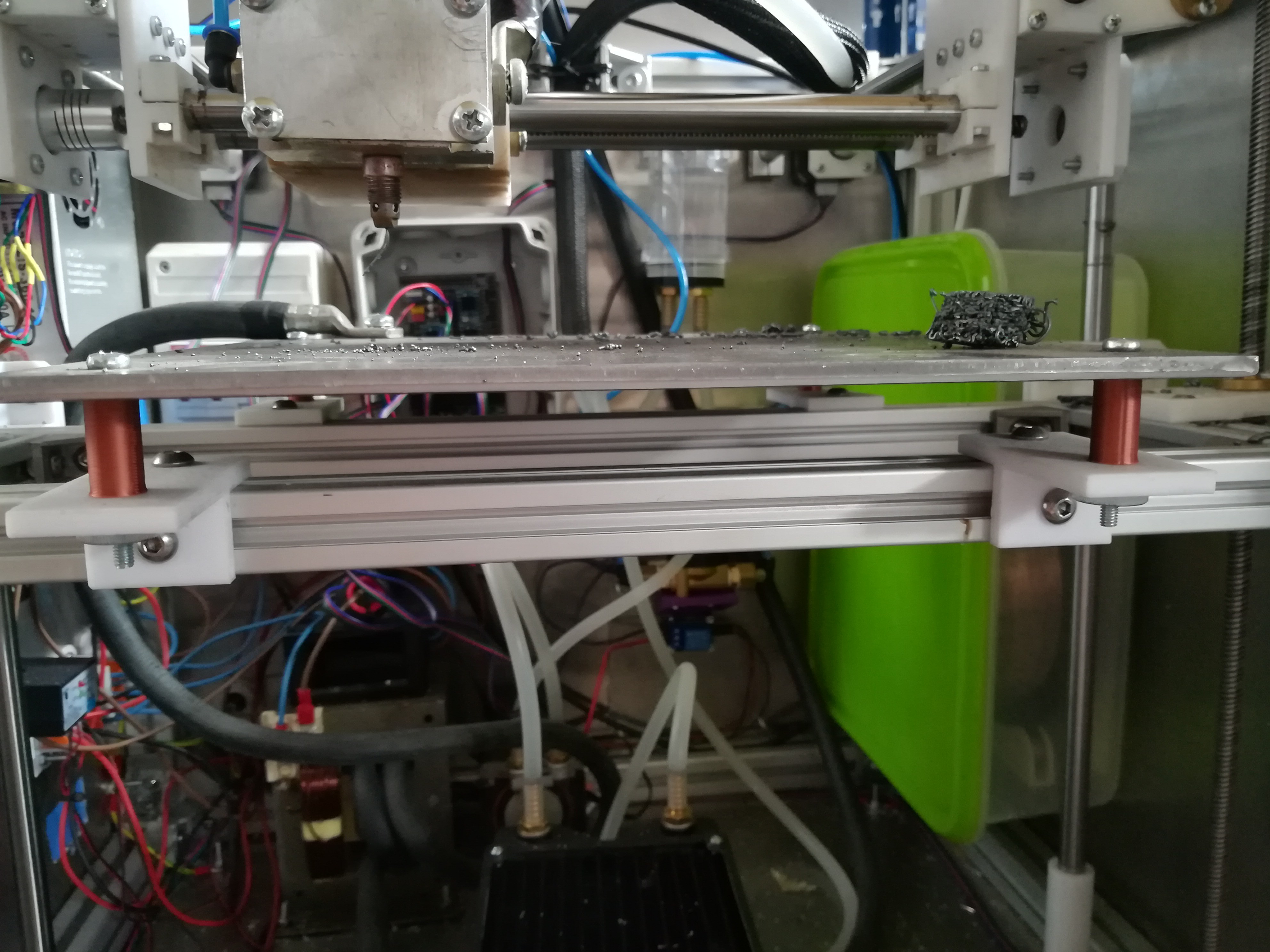

It looks like nothing, but it is actually better fused together and less brittle than the last 100 attempts. More like a solid piece of metal. The difference was that it got more and longer contact with the nozzle, so that the whole part got heated incandescent and therefore better fused together until it got loose from the buildplate. So I think more contact and therefore more heat could be the answer.

I removed the springs from the buildplate to make the construction more rigid.

I think I will give every print a starting layer and an ironing phase, before the printed object starts. Like printing the first layer with some distance to prevent arcing and ironing the second layer down to get a nice flat surface to print on.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.