The summer heat brought the nozzle's 1st real test. It definitely needs more range. The leading idea for adding more range is not using the boundary sensors for detecting runaway motors.

Experience has shown the nozzle never needs the boundary sensors & never has to be reset. It would be too much hassle to completely eliminate the boundary sensors, but they don't have to really stop the motors.

The fully automatic reset routine can be replaced with a manual reset of the nozzle angle. The confuser would reset the pitch as before, then the user would manually rotate the angle to within a few steps of the magnet, then resume the reset routine by searching for the precise angle boundary. It would require no hardware changes.

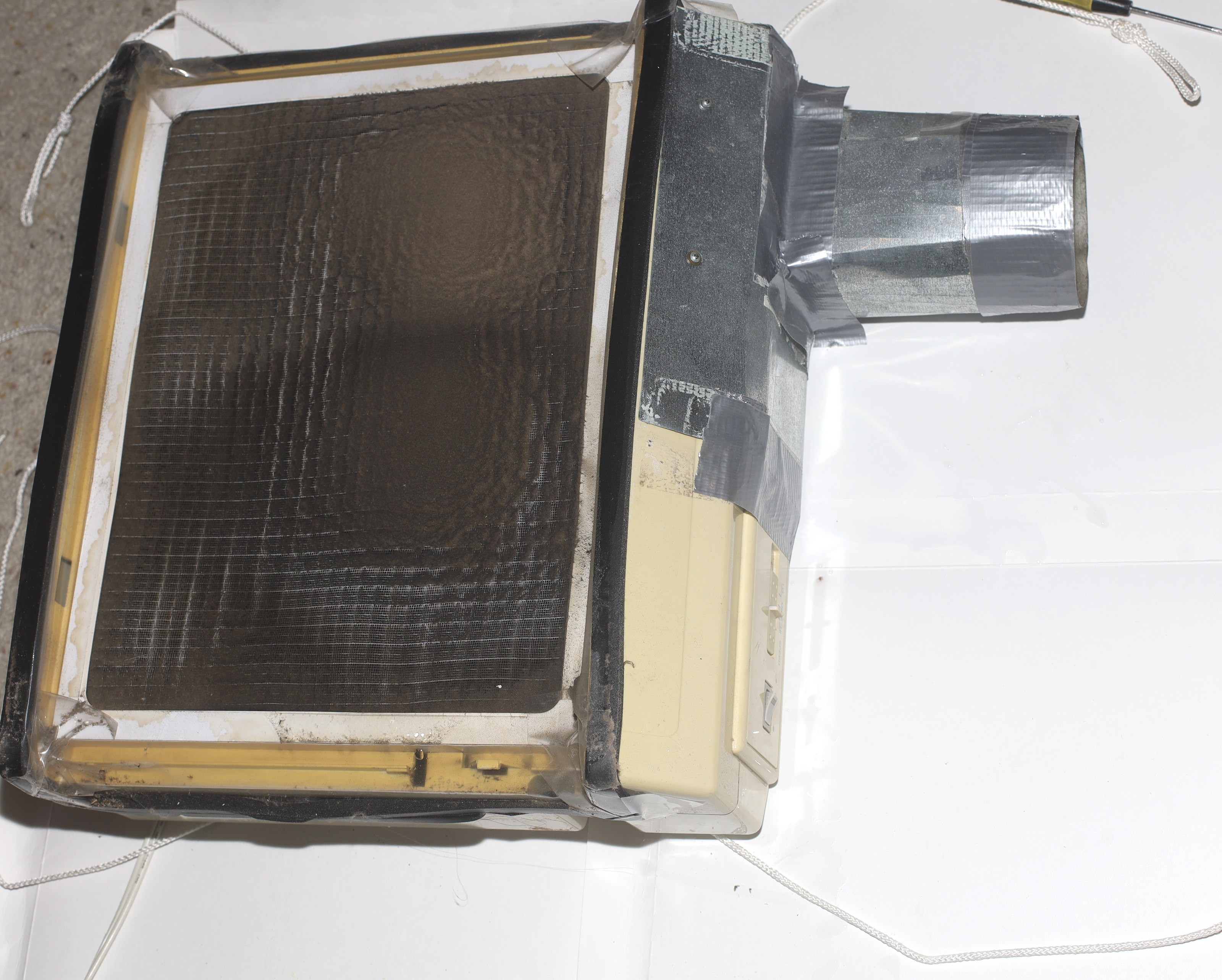

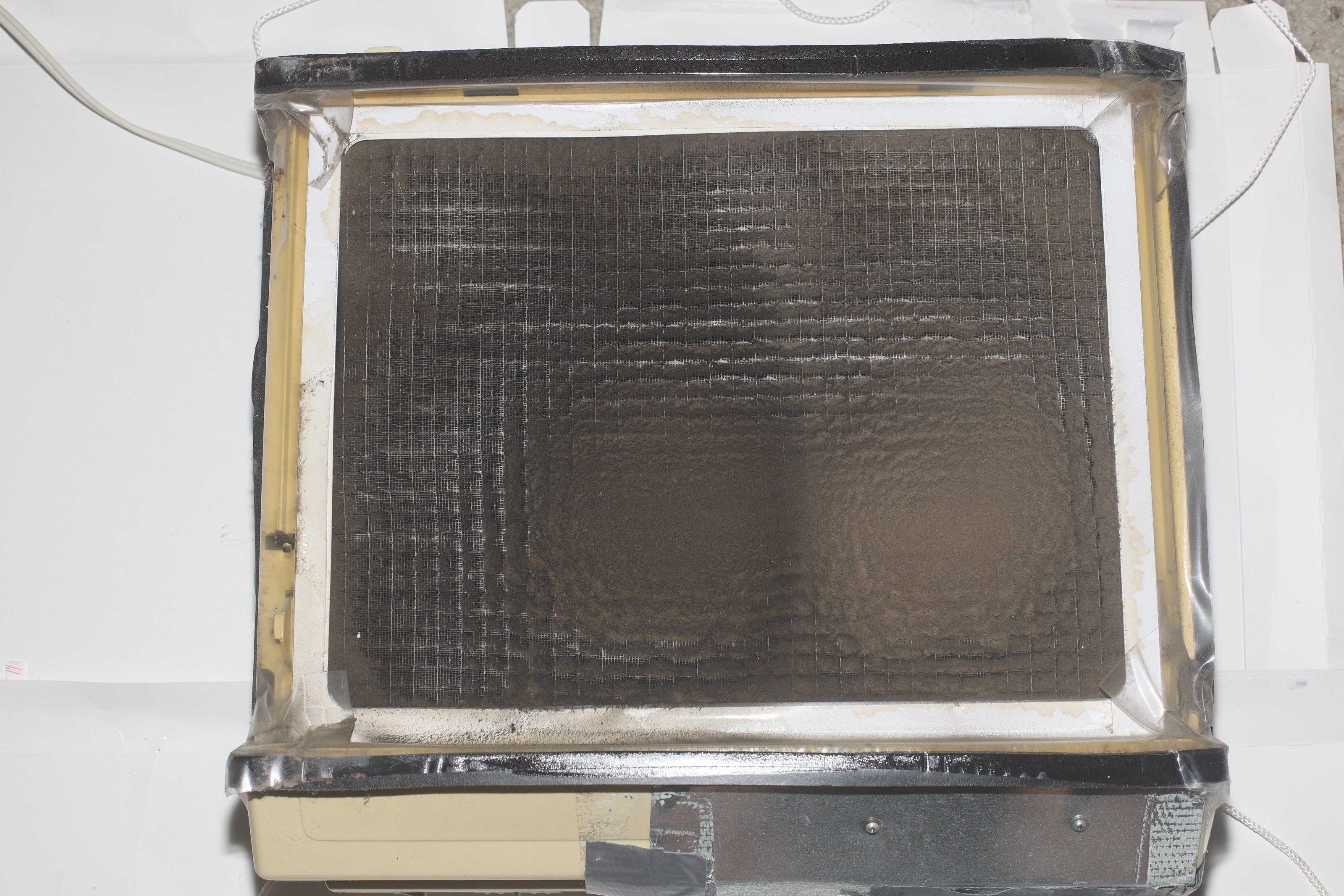

After spending 3 hours replacing another filter, ideas returned for making a complete blower, customized for easy cleaning. The filter would sit inside an inset notch, making it easy to seal the edges with tape. The edges would be flat, making it easy to scrape off all the critters. This one would be made of many smaller blowers that could be individually printed in 1 piece. The smaller blowers would still be the largest the printer could fit.

There's a slight benefit to having the exit nozzle change diameter. The leading plan is having interchangeable nozzle extensions. The interchangeable extensions just wouldn't be F-35 compliant.

The whole thing could be made lighter with a year of lessons learned about minimum tolerances for PLA. The mighty 300:1 N20 motor with encoder is still in stonk.

https://www.adafruit.com/product/4641

Being a much more precise encoder, it would be susceptible to losing count if it wasn't wired in quadrature mode.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.