Bill Of Material (BOM)

Link to the BOM. Most of the parts are off the shelf or 3D print. The four camshafts are custom made, I will explain these in a future instruction post.

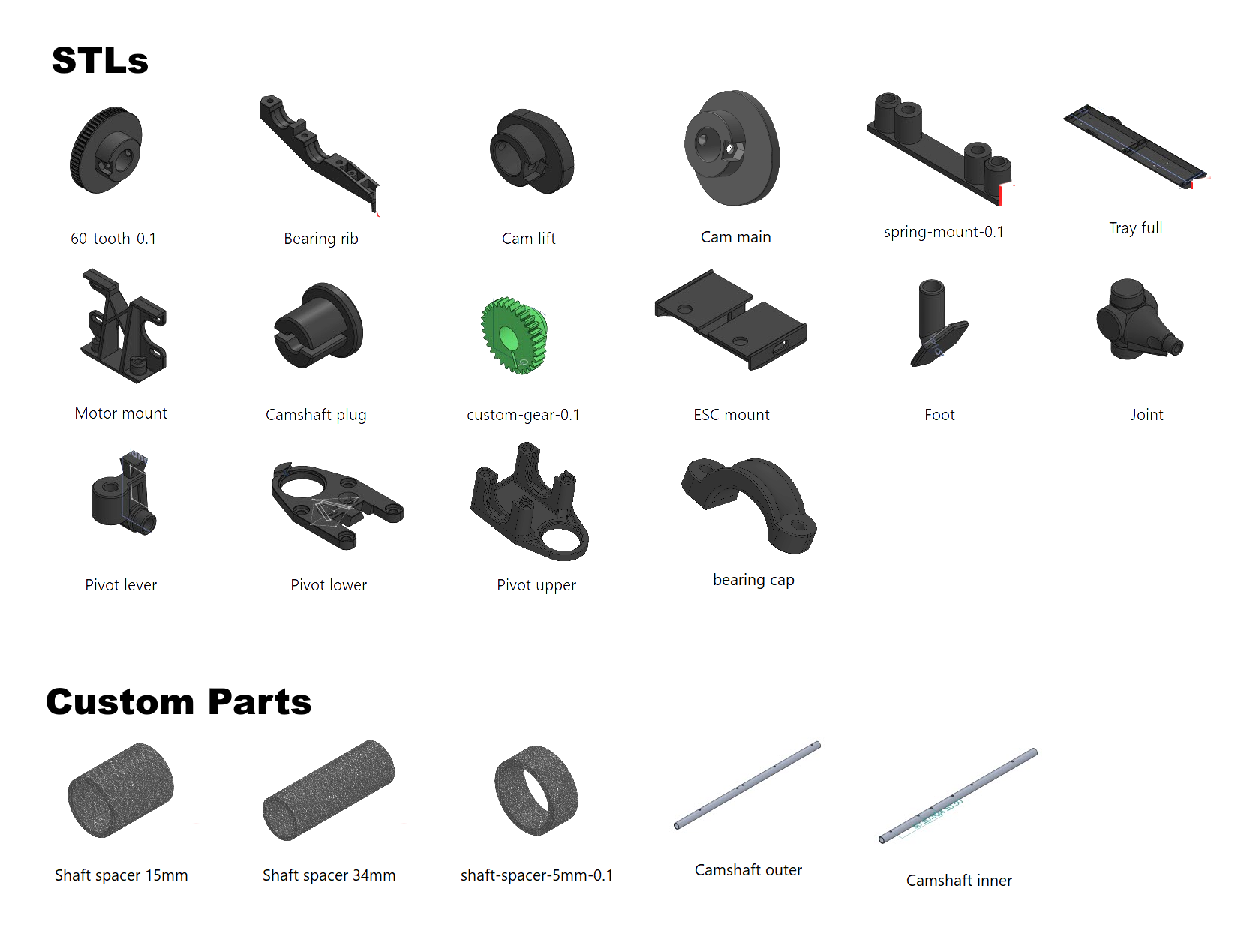

STLs and Printing Tips

Link to STL zip. The STL parts where designed to print on my Lulzbot Mini 6" with 0.5mm nozzle. Your results may vary so I recommend you print one of each part before printing all the parts, just in case you need to make some printing adjustments.

Print cam-lift.stl and cam-min.stl with strong or stiff material like nylon or PLA. All the other parts I used ABS. Use whatever material you like but the cams need to be a strong material because the bearings impart a lot of cutting stress during opertion.

gears.stl and 60-tooth-pulley.stl may speifically need a small (0.5mm) print nozzle. This is because of the detail required in the teeth. I've never tried to print them on a nozzle bigger than 0.5mm. If you try a bigger nozzle please let me know how it turns out.

Don't print all the Tray files; choose the '12 inch printer' file if you have that size print bed. Used the other 3 files if you have smaller print bed.

Print all the parts in the XYZ orientation that they come in. This is to maximise component strength. Also, some parts will require support material.

Except for 60-tooth-pulley.stl, print all the parts with maximum fill. Be careful that sometimes 100% fill can bulge a part. So, you might be better off with 90-95% fill. 60-tooth-pulley.stl can happily live with 10% fill.

If you find any mistakes please let me know. Thanks for following.

Russell Munro

Russell Munro

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

link fixed

Are you sure? yes | no

The STL Zip link is giving an error message :/

Are you sure? yes | no