In Log #6 I showed how I had gotten the Hoverboard driving, but now I had to consider how I was going to mechanically link it with specific assistive platforms.

When I contacted a local Occupational Therapist, she showed me two "Standers" that were used by her children clients. These were marvelous mechanical structures designed to support a child with limited, or no muscular strength or stability (my non-medical description).

The two specific devices I reviewed were the Jenx Multi-Stander and the Jenx Standz: Abduction stander. The smaller Multi-Stander is shown below in green, and the larger Abduction stander is shown in yellow.

I had initially thought I would be trying to add a power drive to a lower cost plastic structure, like a toy ride-in car, but these much heavier structures posed a different challenge.

With a cheap toy, there would be no issues making major mechanical mods to incorporate the Hoverboard drive, but these medical devices range in price from $2-5K so any addition of an external power drive needs to be non invasive. Translation: no drilling holes or bending parts.

The good news was that in both cases the casters are removable with a socket wrench, and so I decided to look for ways to use the existing caster mount-points to attached to the hoverboard. The smaller Multi-Stander was available for me to "play with" so I decided to make this my test case.

The tubular caster supports each has a 3/8" hole so as long as I could use a 3/8" bolt, I was golden.

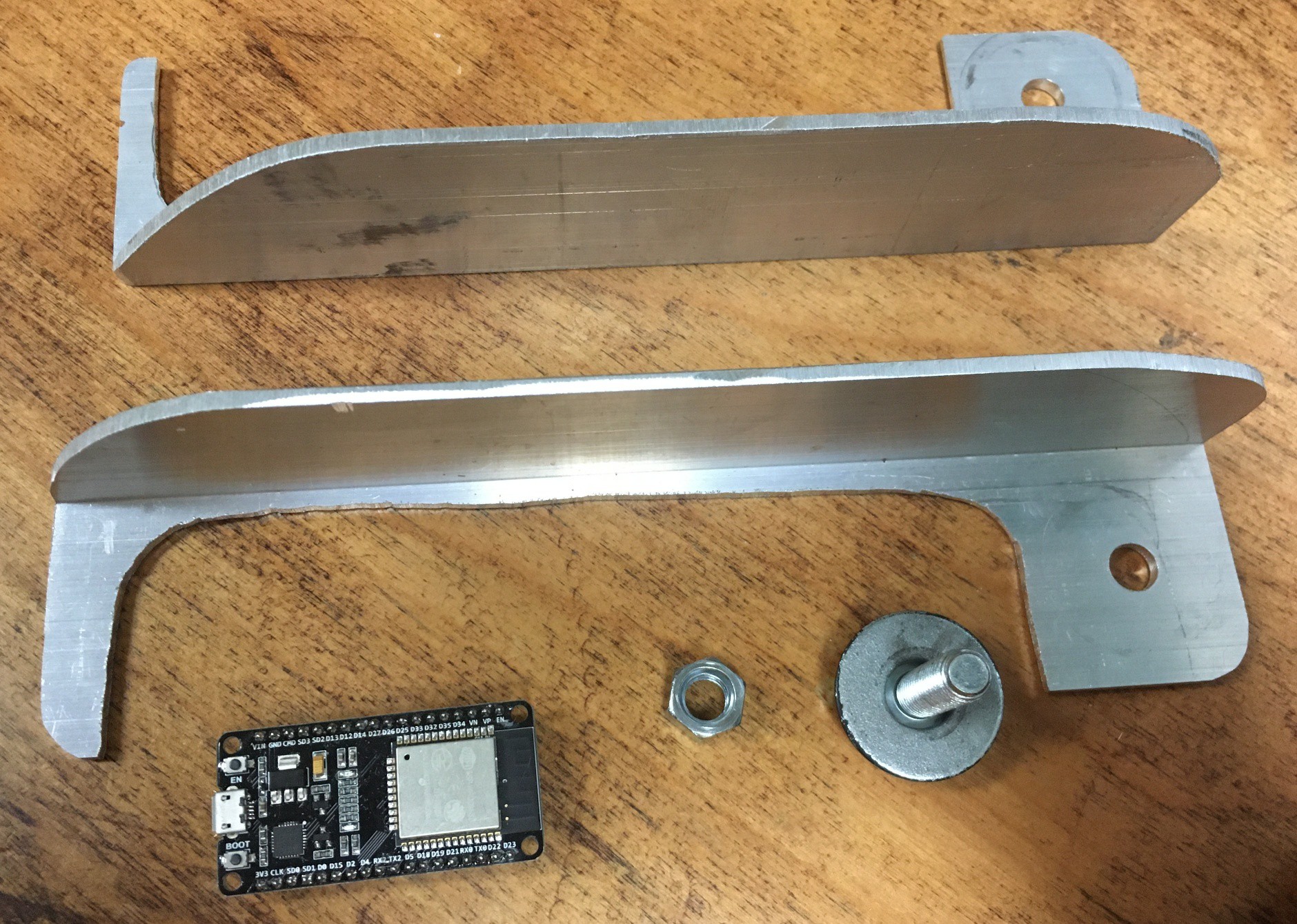

My first approach was to make brackets that could bolt to the Stander (in place of the casters), and then clip on top of the hoverboard (fitting around the wheel guards). Since the hoverboard was too wide to fit inside the caster mounts, it would need to be slung out further back/forward than the casters. This would impose a considerable torque on any mount. I made some aluminum brackets out of 1/8" thick L-channel. I used the L shape to prevent bending.

The brackets worked reasonably well, but they had some issues:

I was hoping that the weight of the Stander resting on the brackets would anchor them to the hoverboard, but this wasn't the case. The rotational torque of the drive when trying to spin the Stander was quite large, and so the hoverboard would lift up and try to spin. As a temporary fix, I used Gorilla Tape to hold the brackets to the hoverboard.

The other issues was that the Stander tended to rotate around the center of the hoverboard, and this caused it to traverse a very wide arc. This made it difficult to navigate in tight spaces.

Ideally, I wanted to move the drive closer to the center of the Standar, without obstructing any of the mechanisms.

Phil Malone

Phil Malone

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.