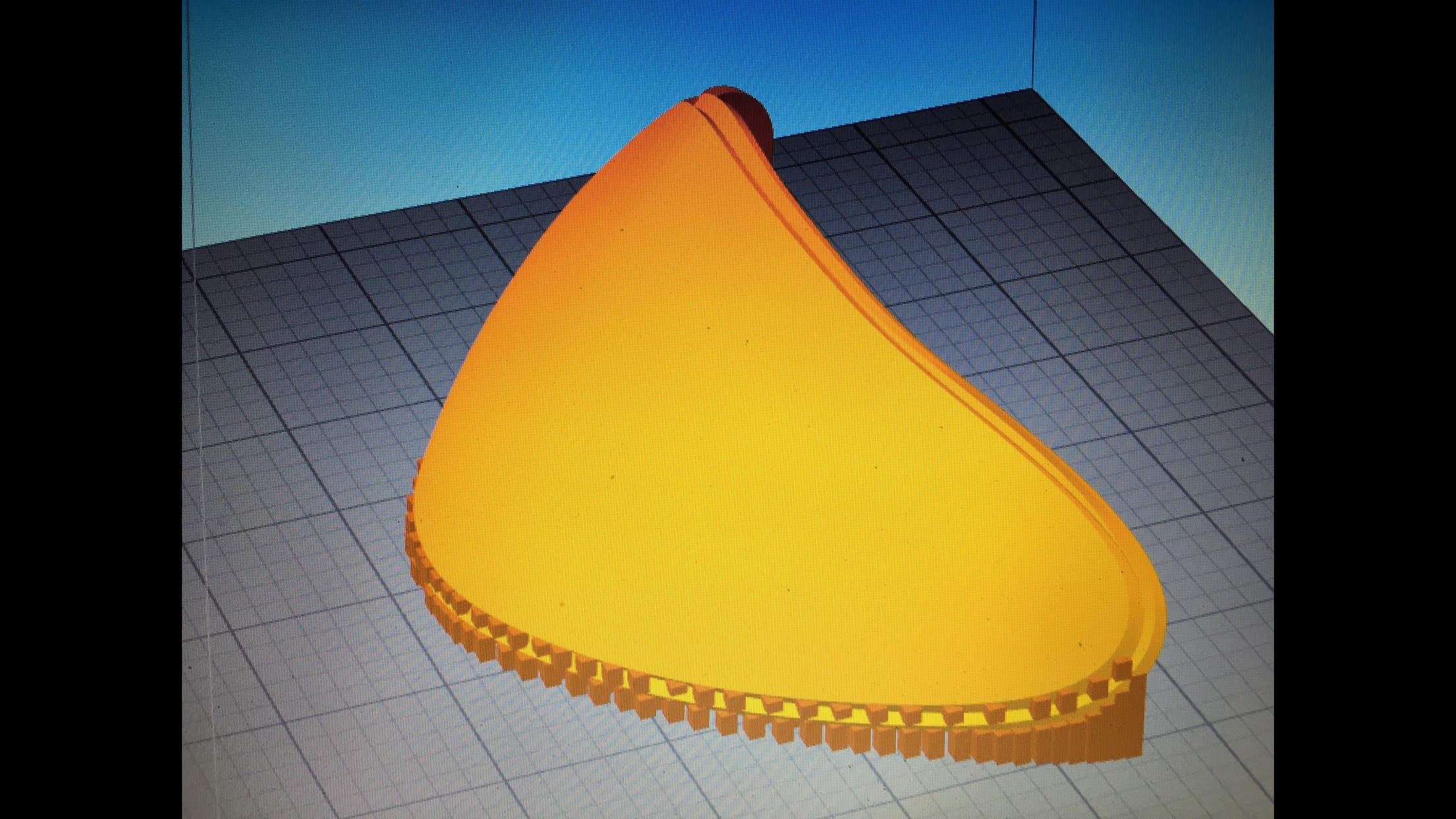

Here we have the model for the clear cover on the Clear View mask. Others have asked how I will handle moisture and humidity in the mask. I will be applying a anti fogging hydrophobic coating normally used in scuba gear and safety glasses. The moisture is expelled normally from the vent when breathing.

Please Like (and follow for more exciting updates) as Seed Grant Money will make or break the success of this project for Hackaday Prize 2020

Please Like (and follow for more exciting updates) as Seed Grant Money will make or break the success of this project for Hackaday Prize 2020

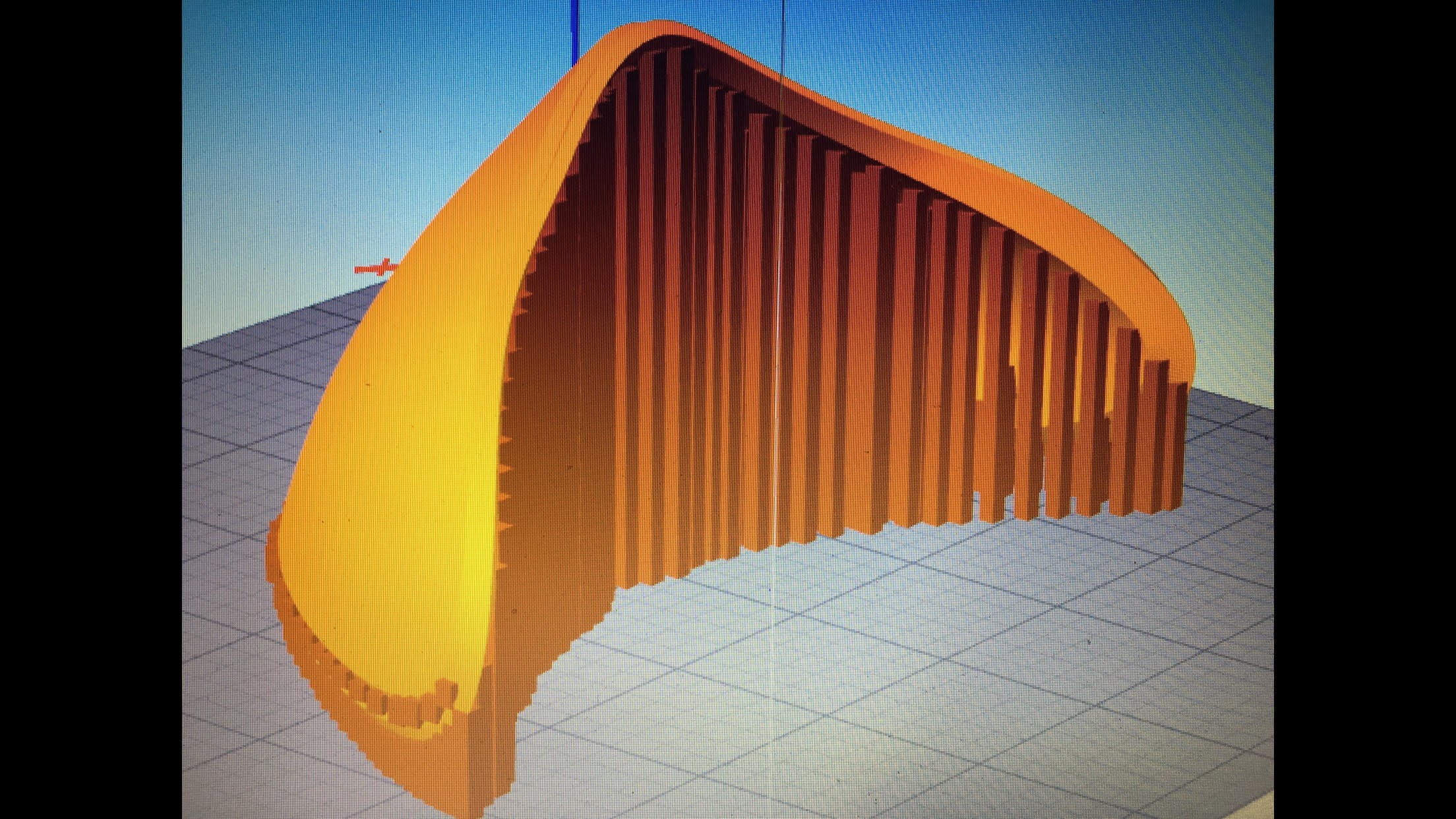

Unfortunately Simplify 3D would not generate supports for this model, no idea why. I had to insert 3 mm supports all the way around by myself manually.

Please Like (and follow for more exciting updates) as Seed Grant Money will make or break the success of this project for Hackaday Prize 2020

Please Like (and follow for more exciting updates) as Seed Grant Money will make or break the success of this project for Hackaday Prize 2020

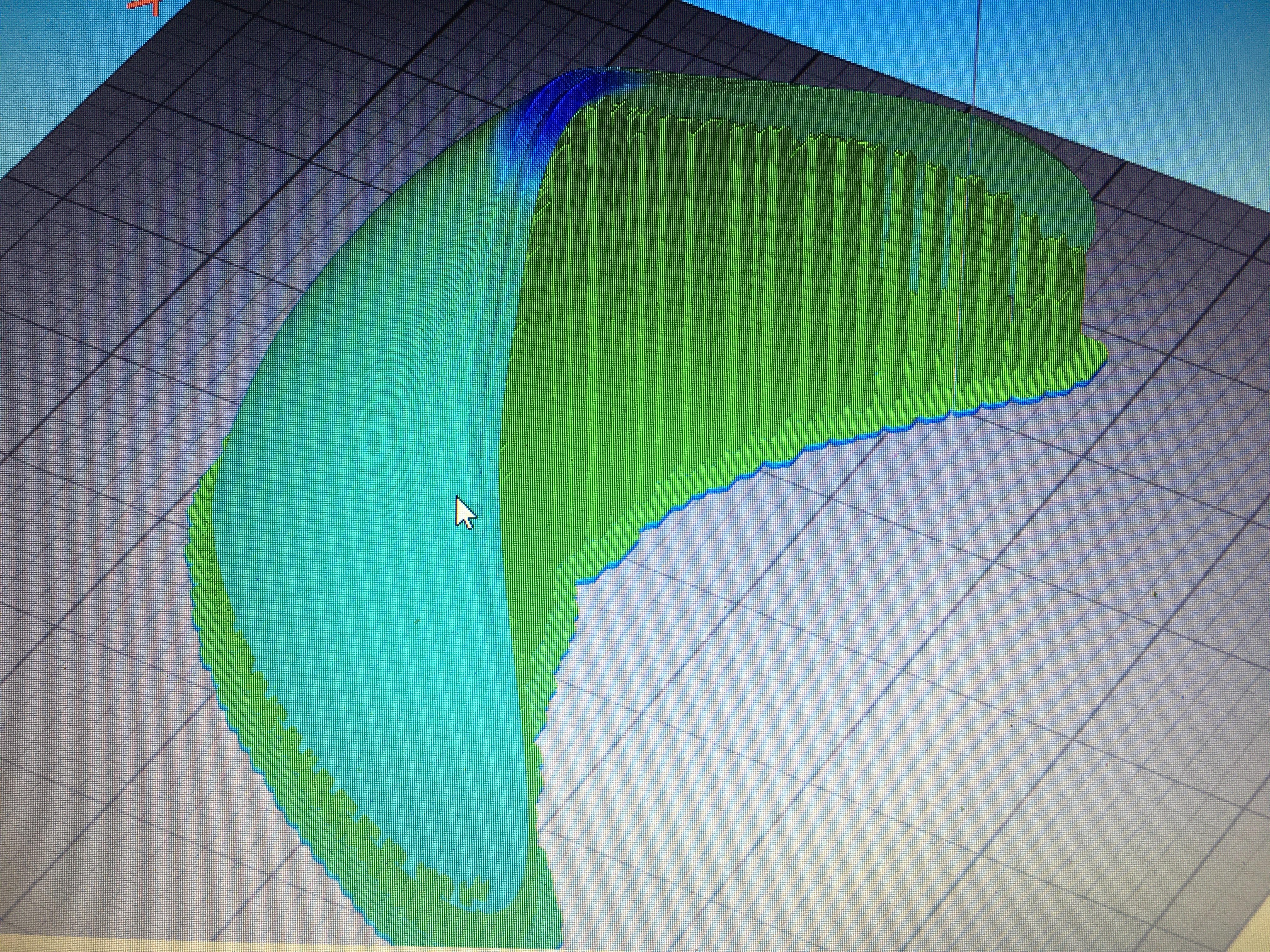

I reduced the speed on this print as well as reduced the layer height to .1mm ( that is twice the resolution of the average 3d print and twice that of all the models we have shown on the product so far). This is an 18 hour print , but the higher resolution is worth it. If no further revisions are needed this would be the top of a vacuum mold buck to make the first clear cover.

Please Like (and follow for more exciting updates) as Seed Grant Money will make or break the success of this project for Hackaday Prize 2020

Josh Starnes

Josh Starnes

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.