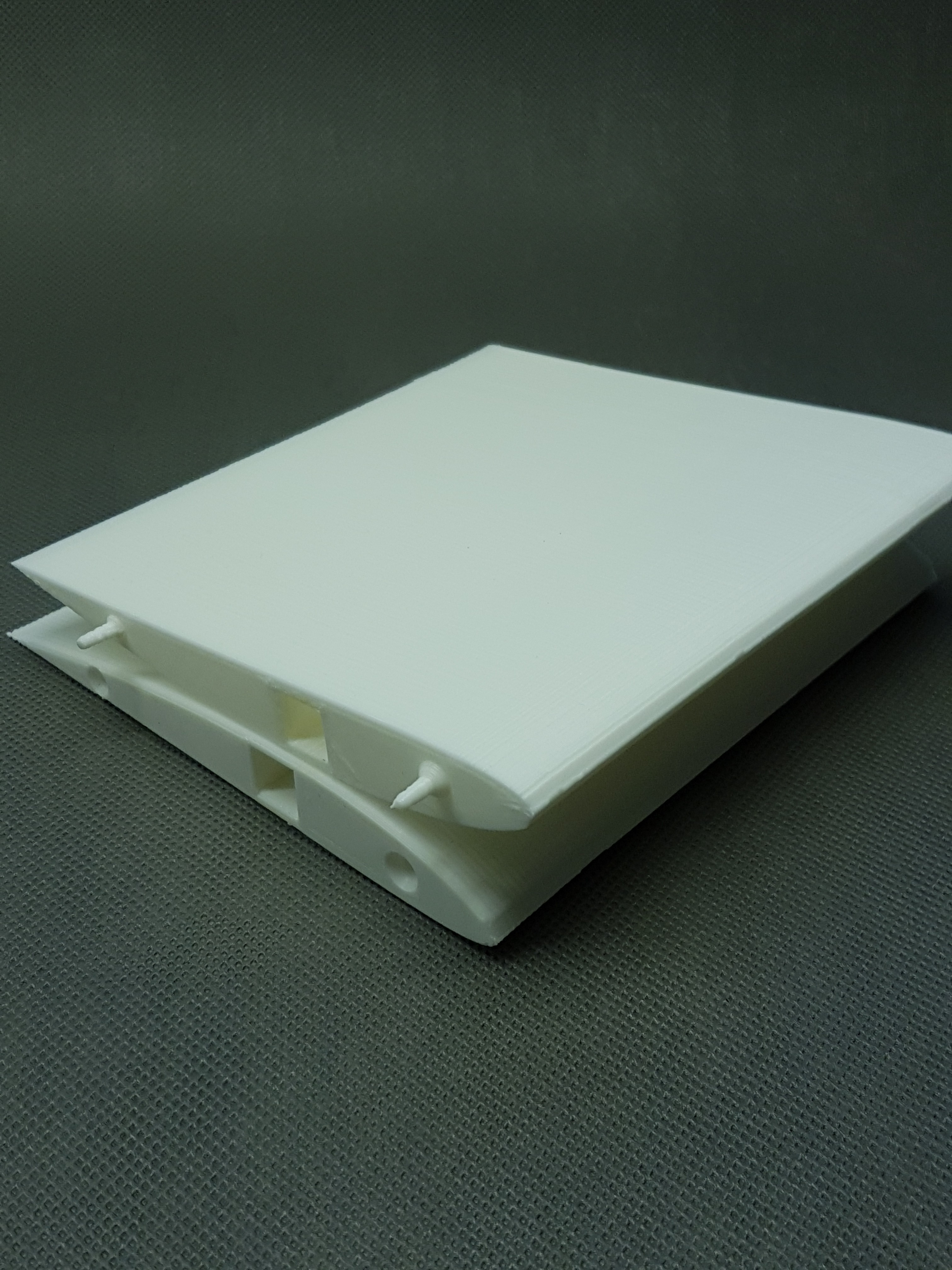

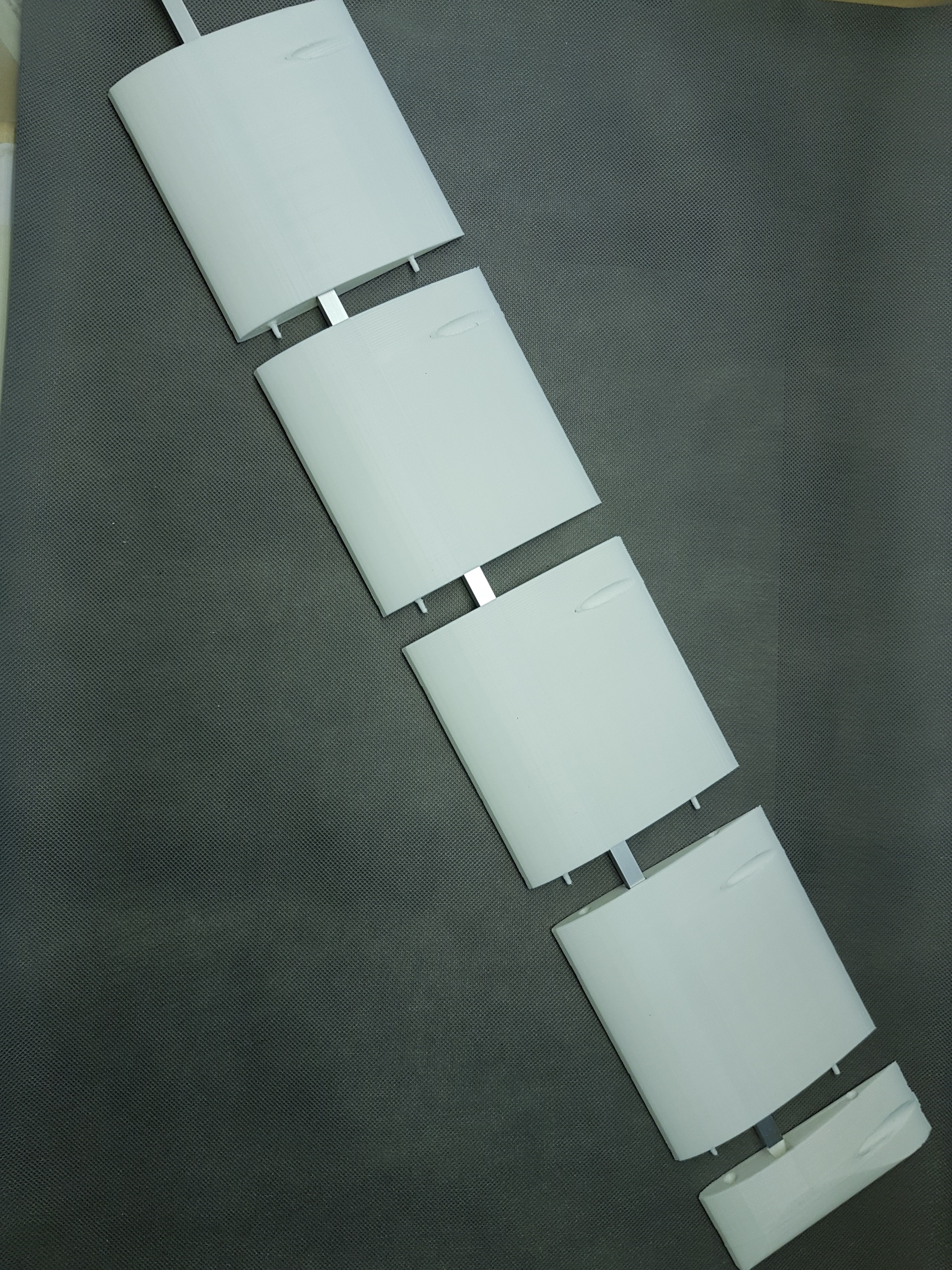

In the meantime, I had also dealt with the wings again. After "Mark1" fit quite well in terms of weight, the wing was not so stable that I thought it could hold out really long. Especially with strong bends, the PLA (printed with 10% infill for weight reasons) already cracked dangerously.

That's why I started developing "Mark2". In my opinion, the two M3 threaded rods were clearly too fragile to support the construction properly.

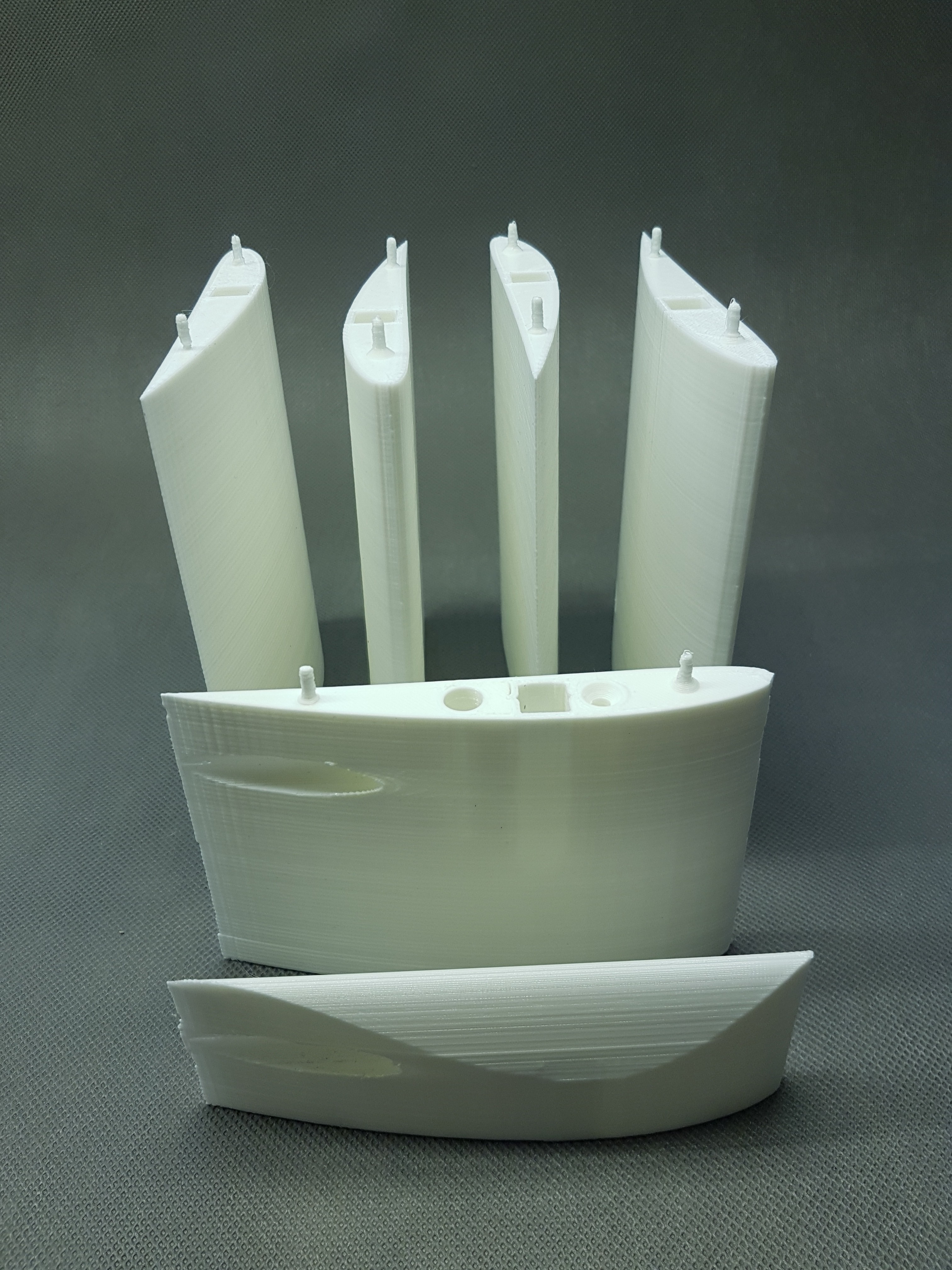

That's why I exchanged the two threaded rods for an aluminum profile. The individual elements of the wings remained almost unchanged. The wing was now clearly more stable.

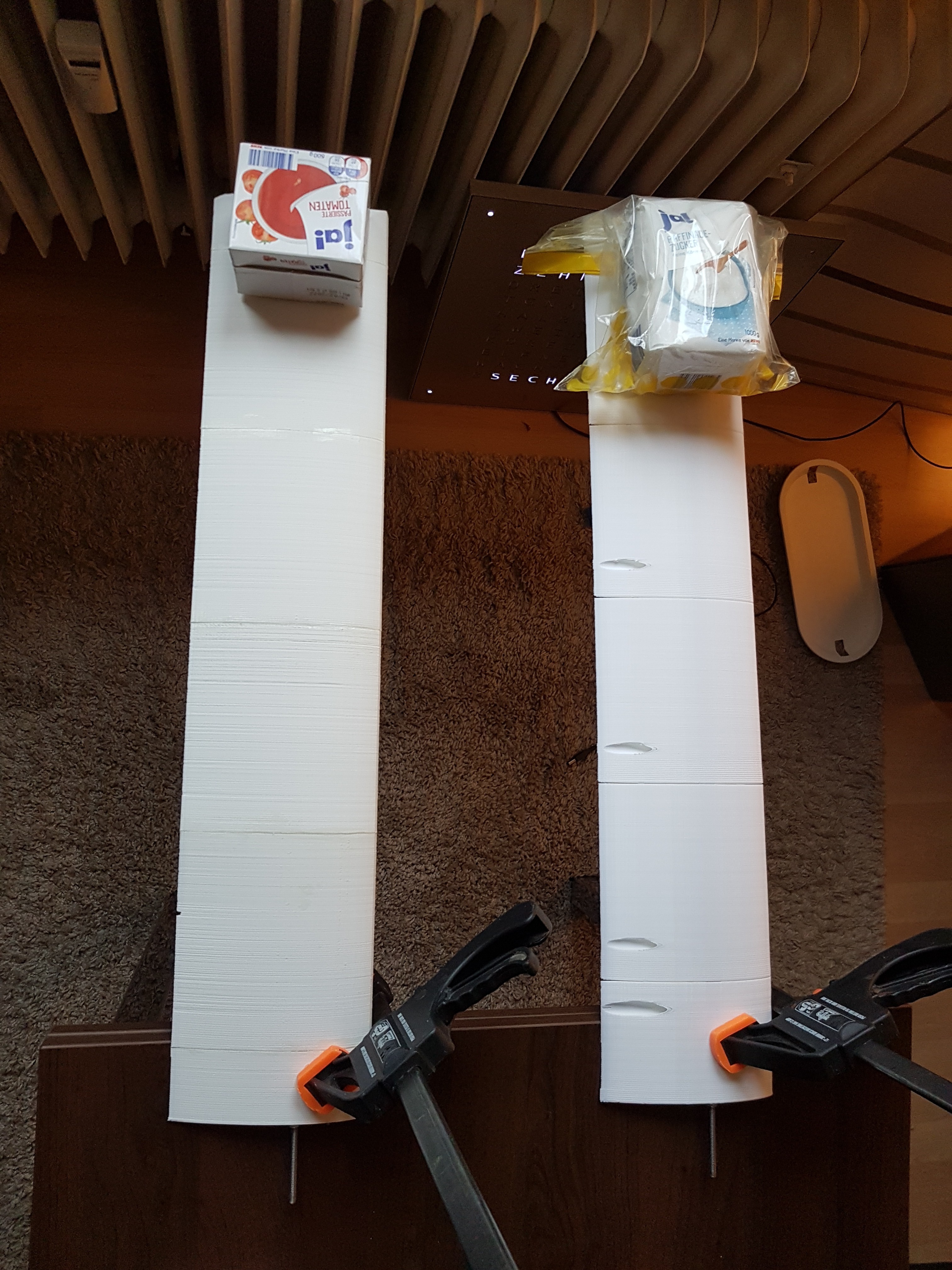

As you can see in the photos, I did a small (scientifically correct) load test with 1kg flour packages. In fact "Mark1" was more stable than I thought. At least he didn't break. However, he made alarming noises. In summary, "Mark2" clearly won this small casting. :)

Disadvantage: The aluminum profile increased the weight of the wing quite a bit. Now the whole wing weighed almost 700 grams, about 150 grams more than "Mark1". Since later three of them should hang on the hub of the turbine, including the mechanics of the pitch adjustment, this would be close to the 3 kg limit. But since there will definitely be a few unbalanced ones, I actually wanted to keep this "rotating mass" as small as possible.

In addition, I noticed that in combination with the (meanwhile created) prototype for the hub of WinDIY there was no possibility to separate the wings from the hub without completely disassembling the entire hub. Actually, I wanted to design the wings to be easily interchangeable. So you could easily remove or replace the wings for transport and repair. :)

Small teaser: There may still be a Mark3. : D

Above picture shows the cracking slit between the parts of "Mark1" during the load test. :/

Fabian

Fabian

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.