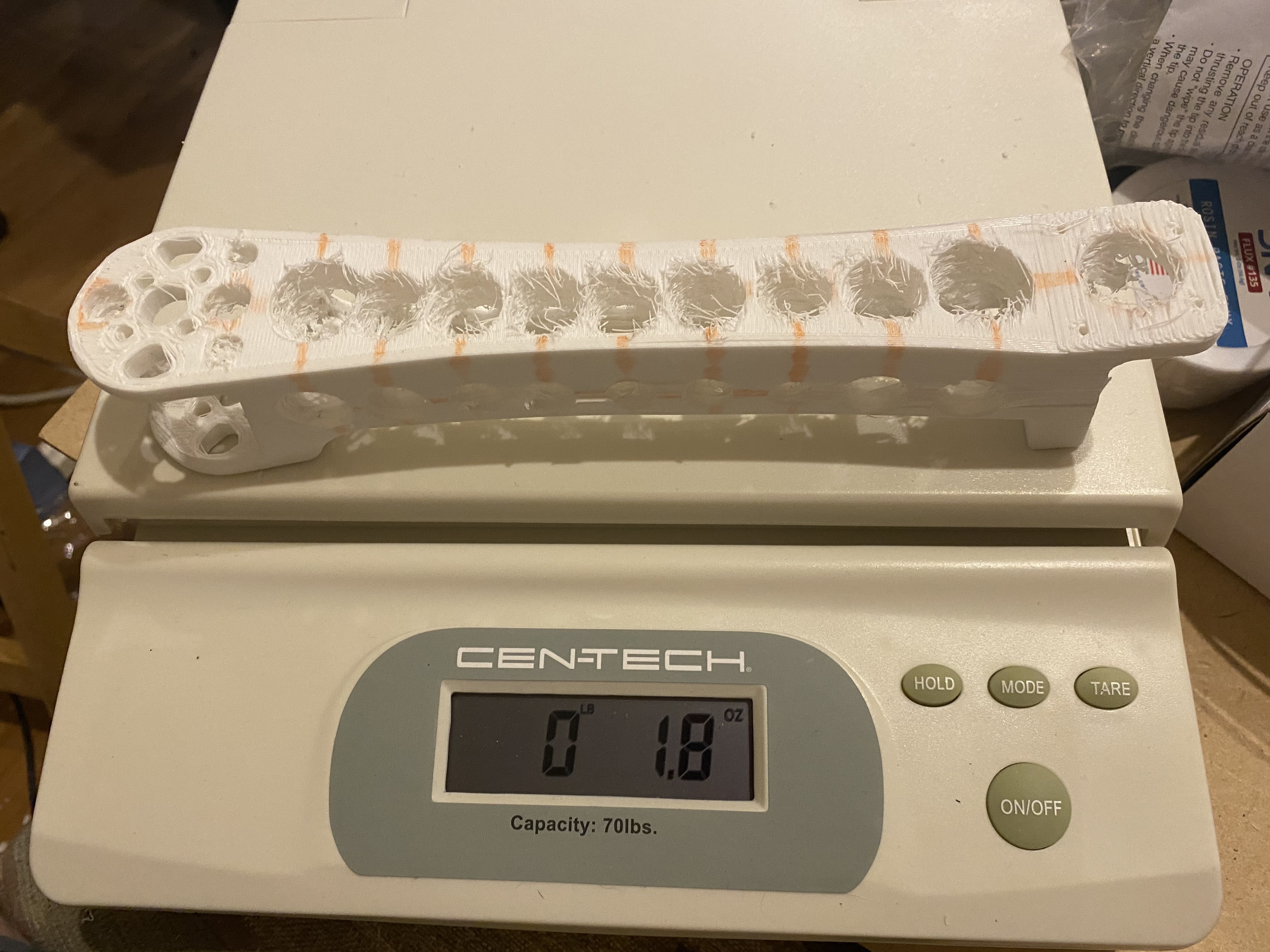

Ok so we are at the point where we need to shave off every ounce we can to make room for a good thrust to weight ratio and allow plenty of ceiling space for additional electronics. I manually drilled out the prototype and found it reduces it all the way down to the original oem part weight, however drilling manually is impractical and makes a mess. So everywhere I have drilled out I am transferring those holes back into the 3D model for efficient weight reduction right off the print bed. The top level with additional frame plate and anti vibration spacers may also be removed for another few ounces dropped off the frame. My challenge at the moment is to make a frame with parts lighter than the originals. Every ounce of weight dropped is equal to gaining another ounce of thrust and flight weight capacity. After some calculations I have found with some weight reduction I can manage to keep the overall power budget below 1000 watts and therefore reduce the requirement of three power supplies down to two power supplies. Only having two power supplies onboard further reduces the weight 1 - 1.4 pounds lighter by itself.

Josh Starnes

Josh Starnes

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.