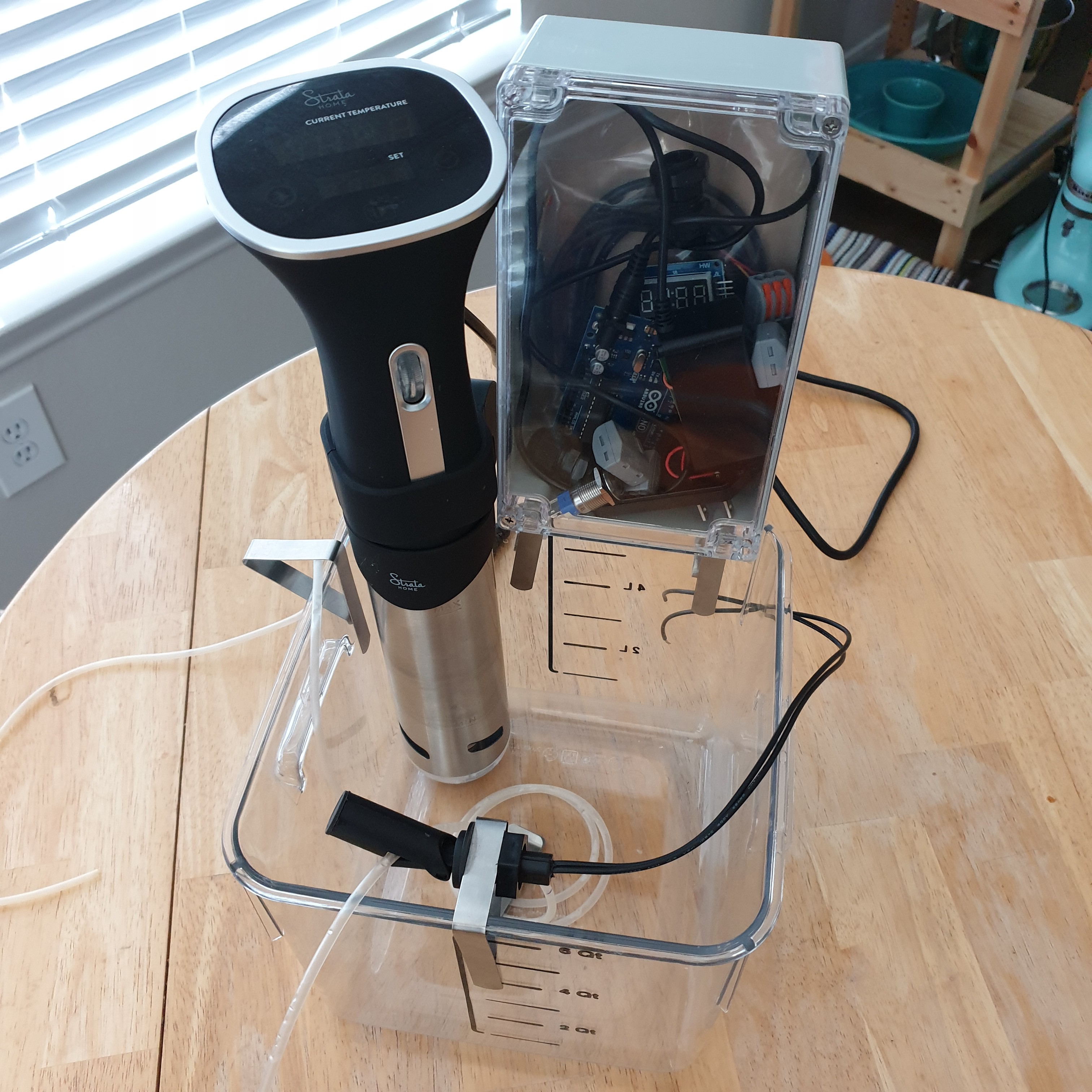

It was decided last week to explore what it would take to develop a safe OpenFluidWarmer design with a sous vide cooker. Testing showed that the constant temperature water bath method with the sous vide cooker was able to meet the thermal performance requirement that the previous two hot plate design could not. Since performance with the sous vide cooker has been so promising, the recent design effort has focused on improving the safety and reliability of the system. The image above is the latest build progress towards the OpenFluidWarmer sous vide cooker prototype.

The most notable design compromise with the sous vide cooker design is the amount of time it takes for the device to warm up and be ready for use. The two hot plate design could warm up in less than 60 seconds from 25°C to 105°C. Whereas the sous vide cooker design takes about 11.5 minutes to warm the water bath from 25°C to the lower required heater set point temperature of 70°C. It is a little misleading to make this comparison because the two hot plate design was never able to meet the thermal performance requirement at the 105°C set point anyways.

At this time, I don't believe a warm up time close to 11.5 minutes to be a significant issue with this warmer. The device could be turned on 10 minutes before the procedure or run continuously during a procedure when need for warming IV fluids was anticipated. Then the IV tubing can be placed into the water bath at a moments notice when warming is needed.

The sous vide cooker design starts to outshine the two hot plate design when it comes to operational redundancies and simplicity of assembly. The sous vide cooker itself includes an independent power button, temperature controller, and temperature display. The additional system housed in the electronics enclosure (what I am calling the sous vide cooker "safety companion") includes button controls, a sous vide cooker power disconnect, temperature monitoring, and state and fault indicator displays. If for whatever reason the sous vide cooker failed, the "safety companion" system will alert the user and potentially disconnect the power. If the "safety companion" failed, it's very possible that the sous vide cooker will continue to operate as intended without issue. Hardware redundancy really helps to ensure safe operation of the device. On top of that, it's very convenient that a full package, cost-optimized constant temperature bath solution like sous vide cookers are readily available for purchase. All you have to do is supply power to it.

Instead, the two hot plate architecture only included one microcontroller/control system and no backups if that failed. Adding redundancies to the two hot plate architecture would greatly increase the complexity of the hardware, software, and assembly.

John Opsahl

John Opsahl

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.