This part of the tool is the main event, even so, we design a multi-tool kit, we put all our effort to create the best solution to address the challenge that Field Ready put in our hands. In this case, this log will be only about the design aspects of the head, the electronics will be addressed in specific logs.

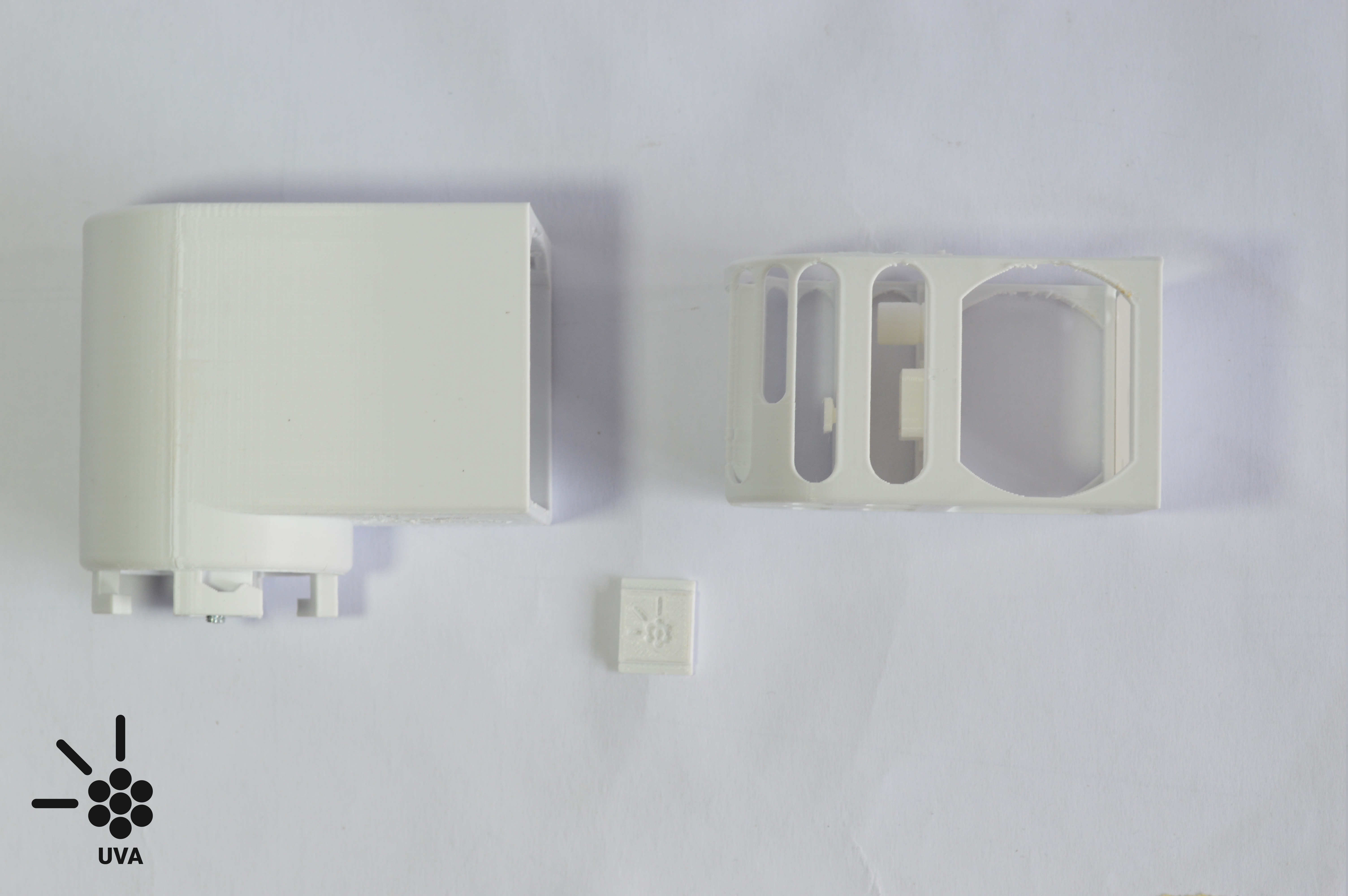

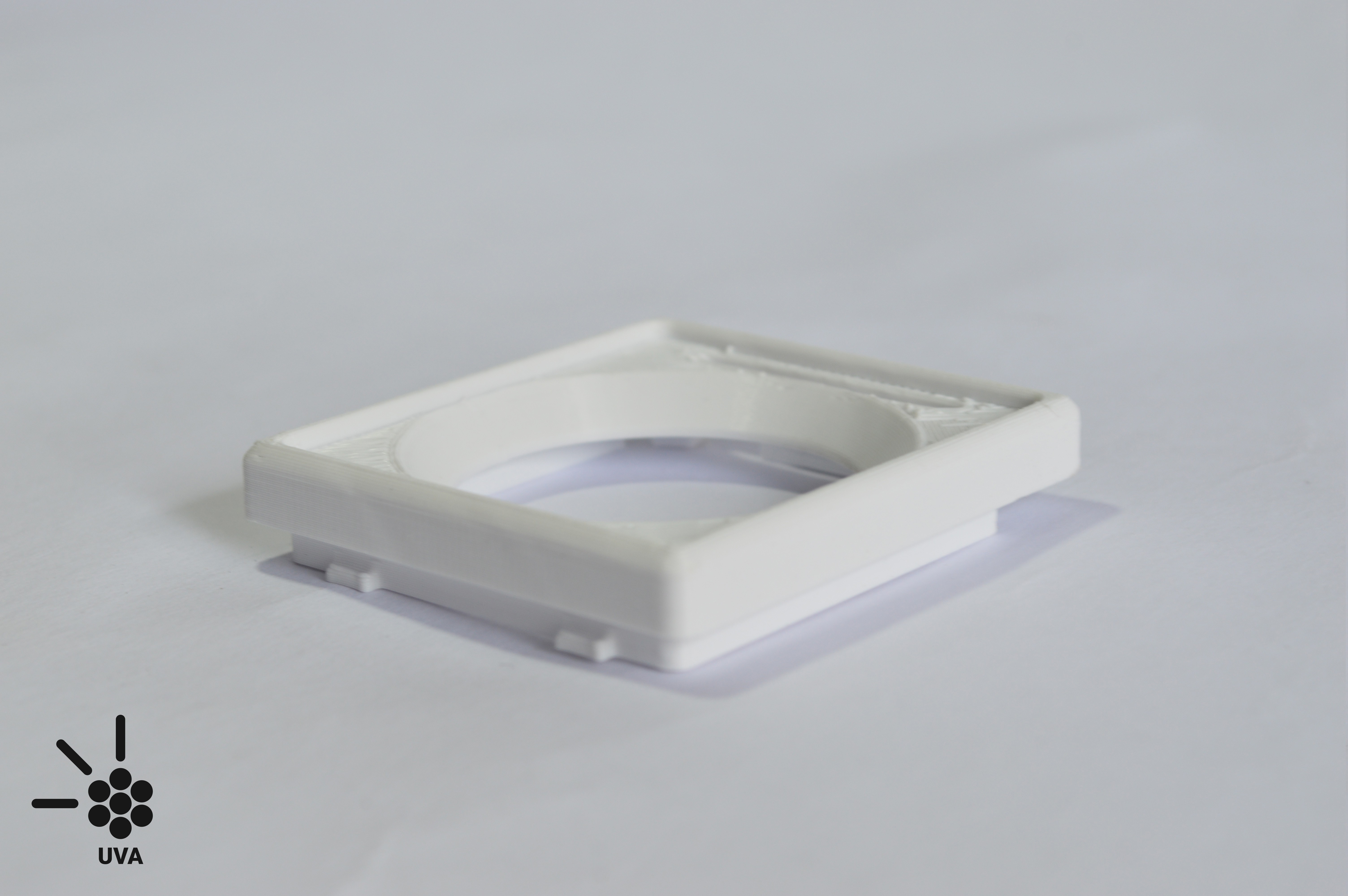

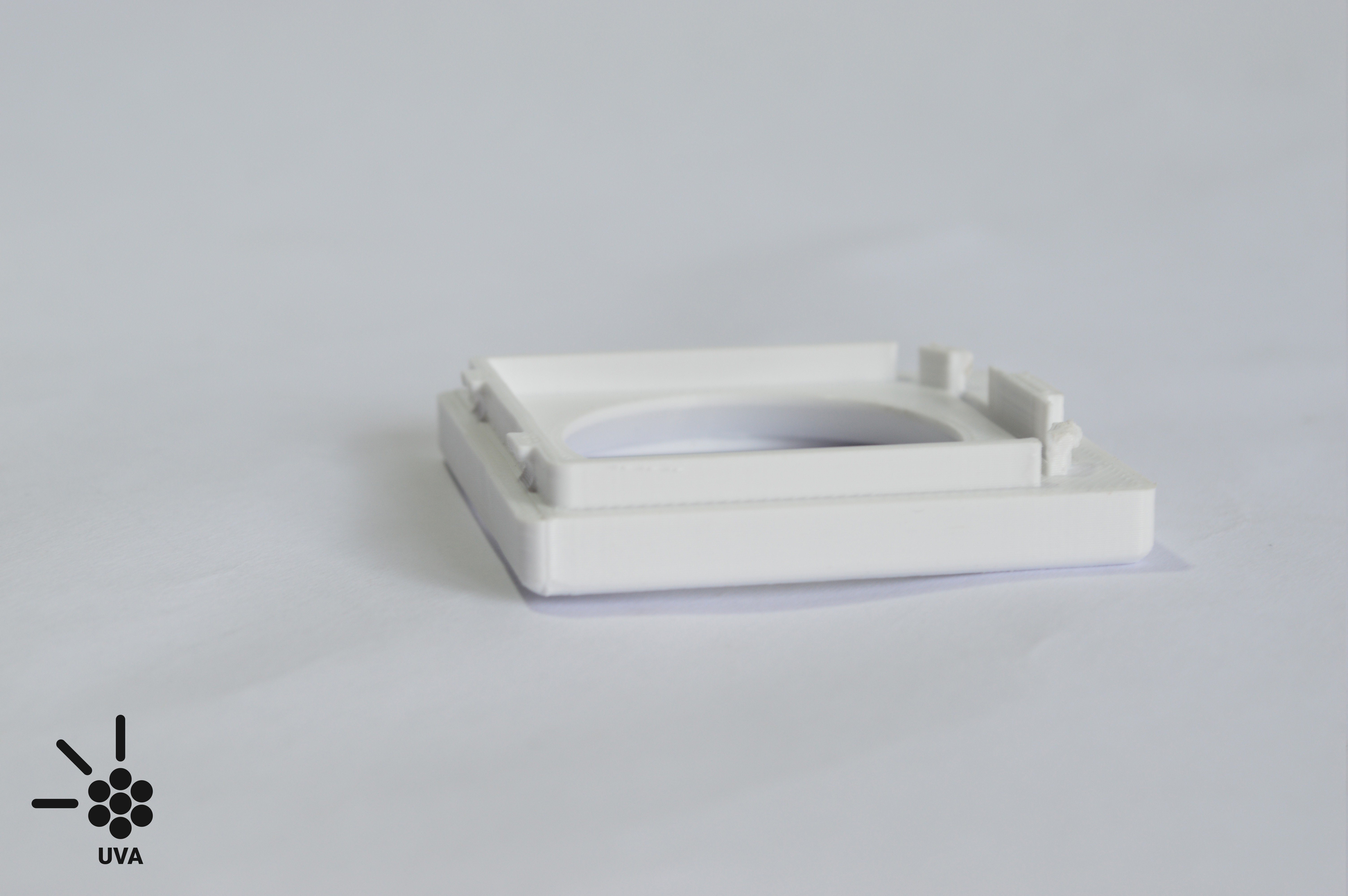

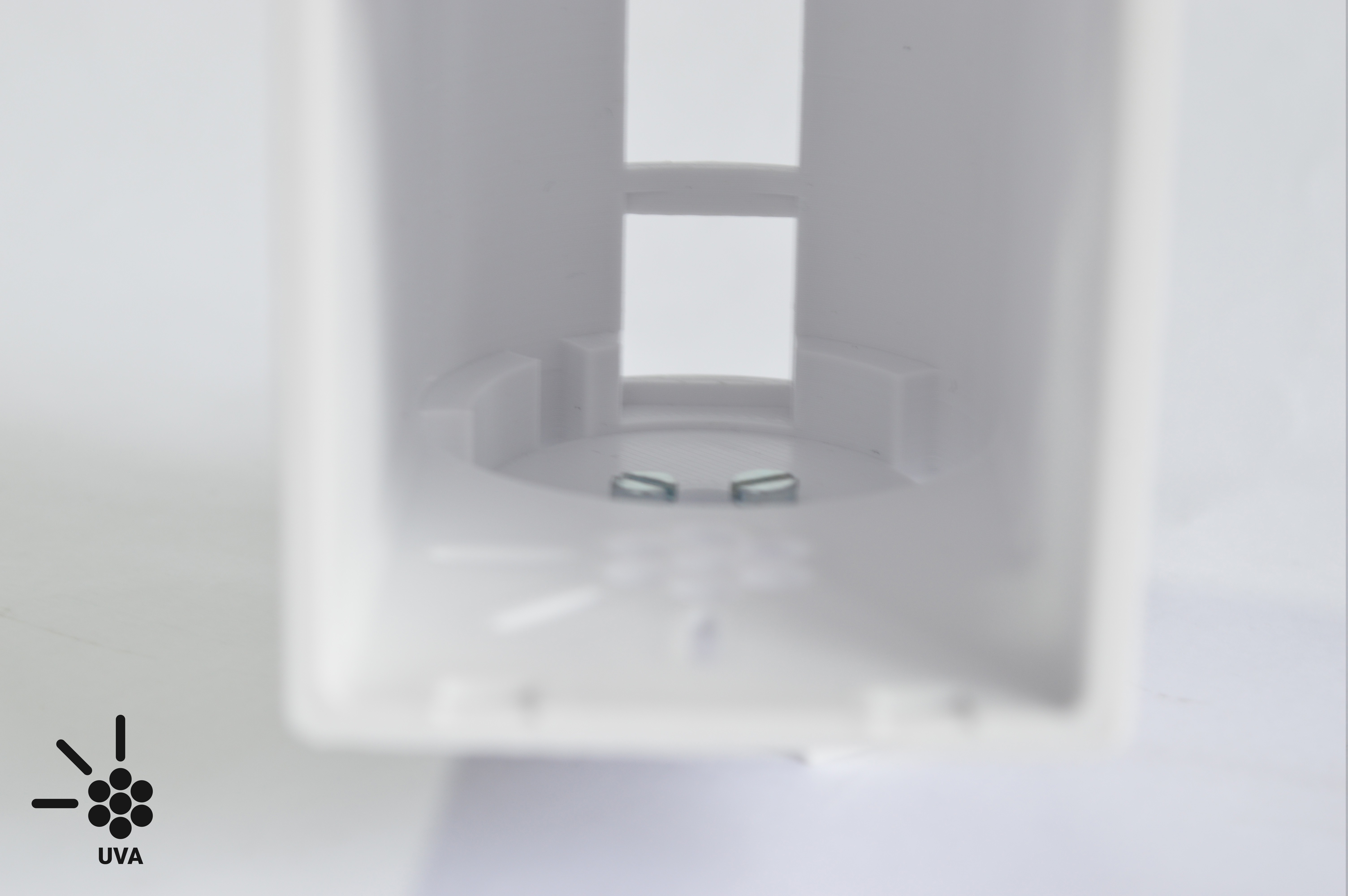

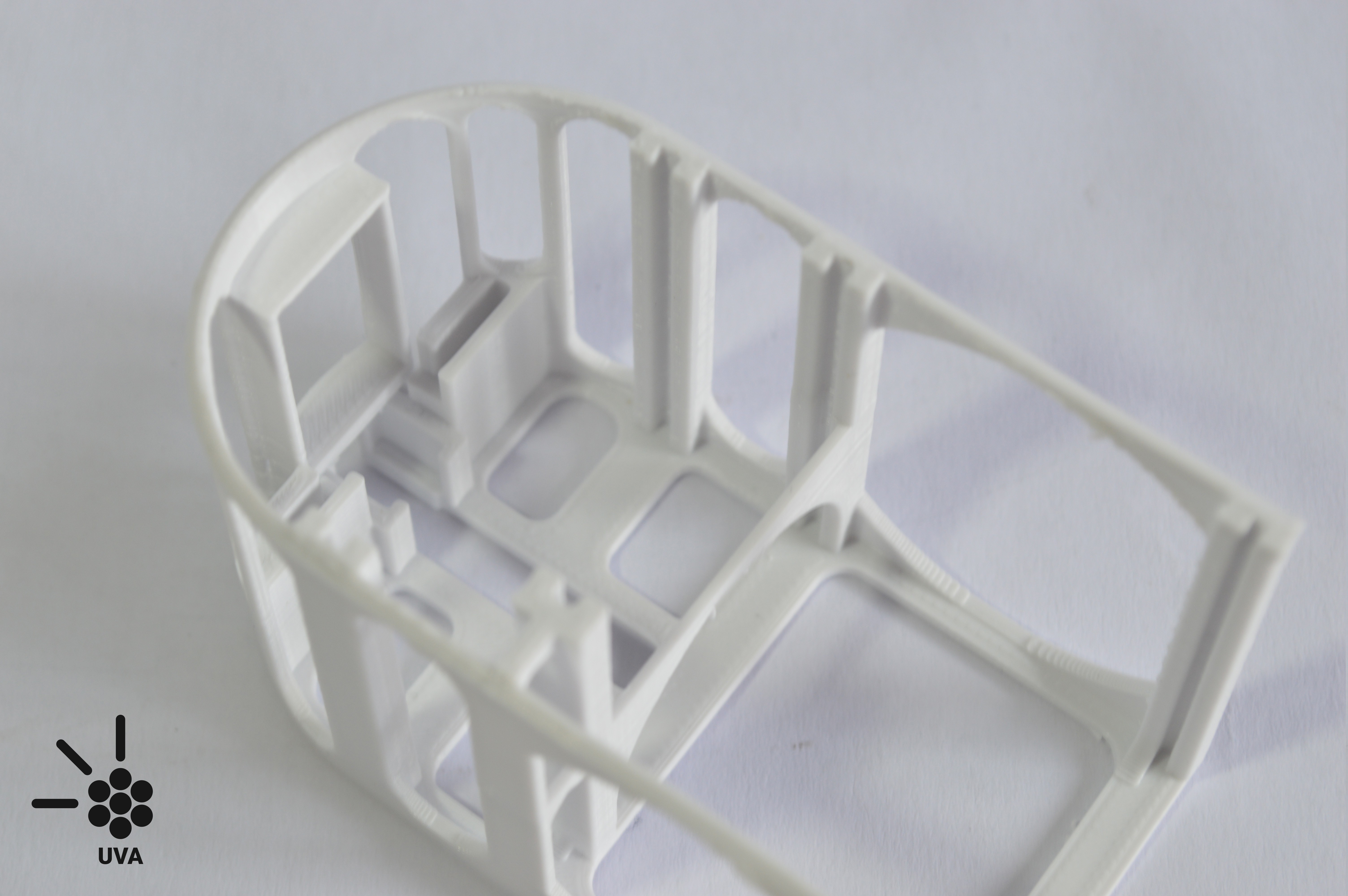

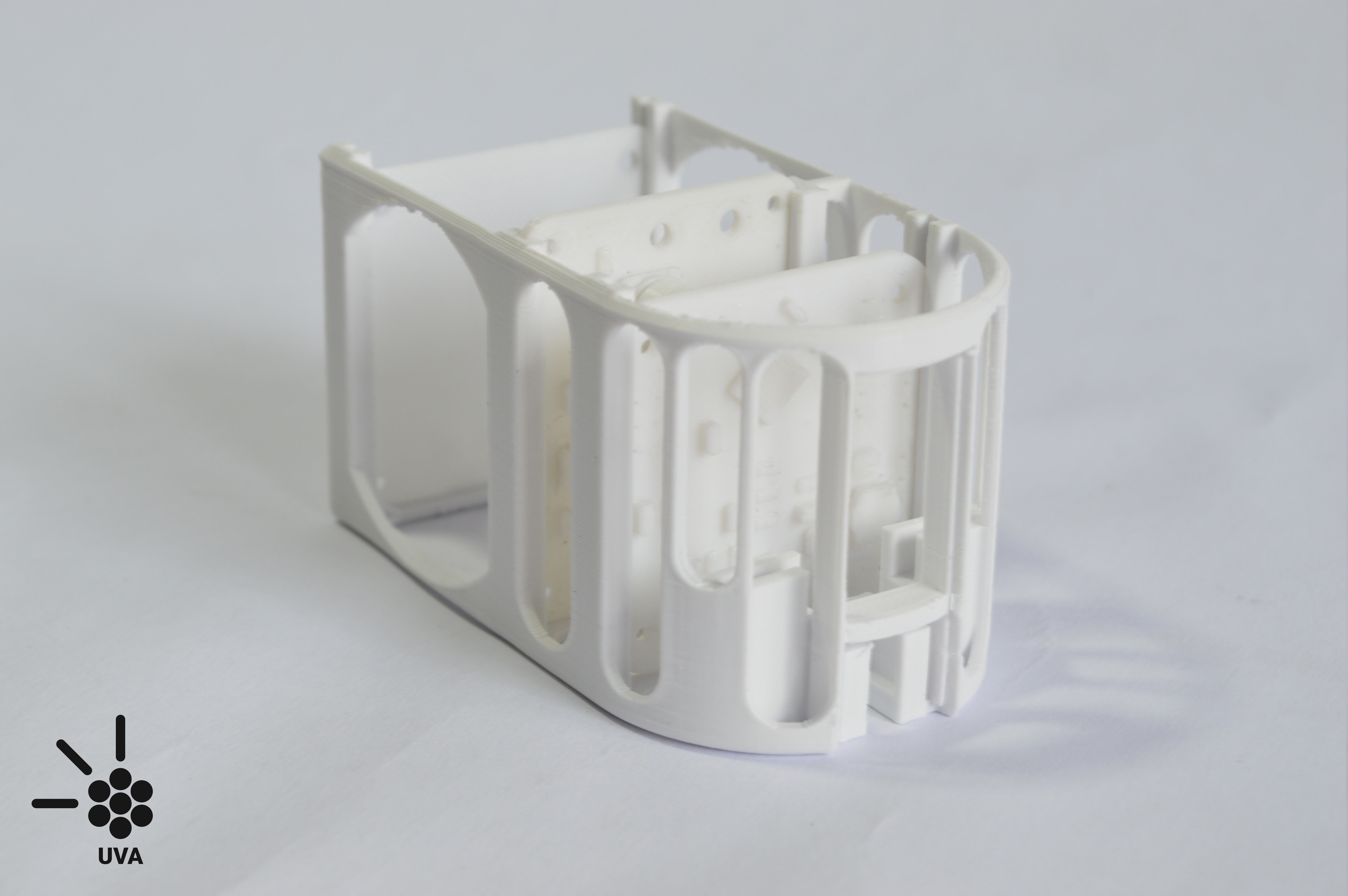

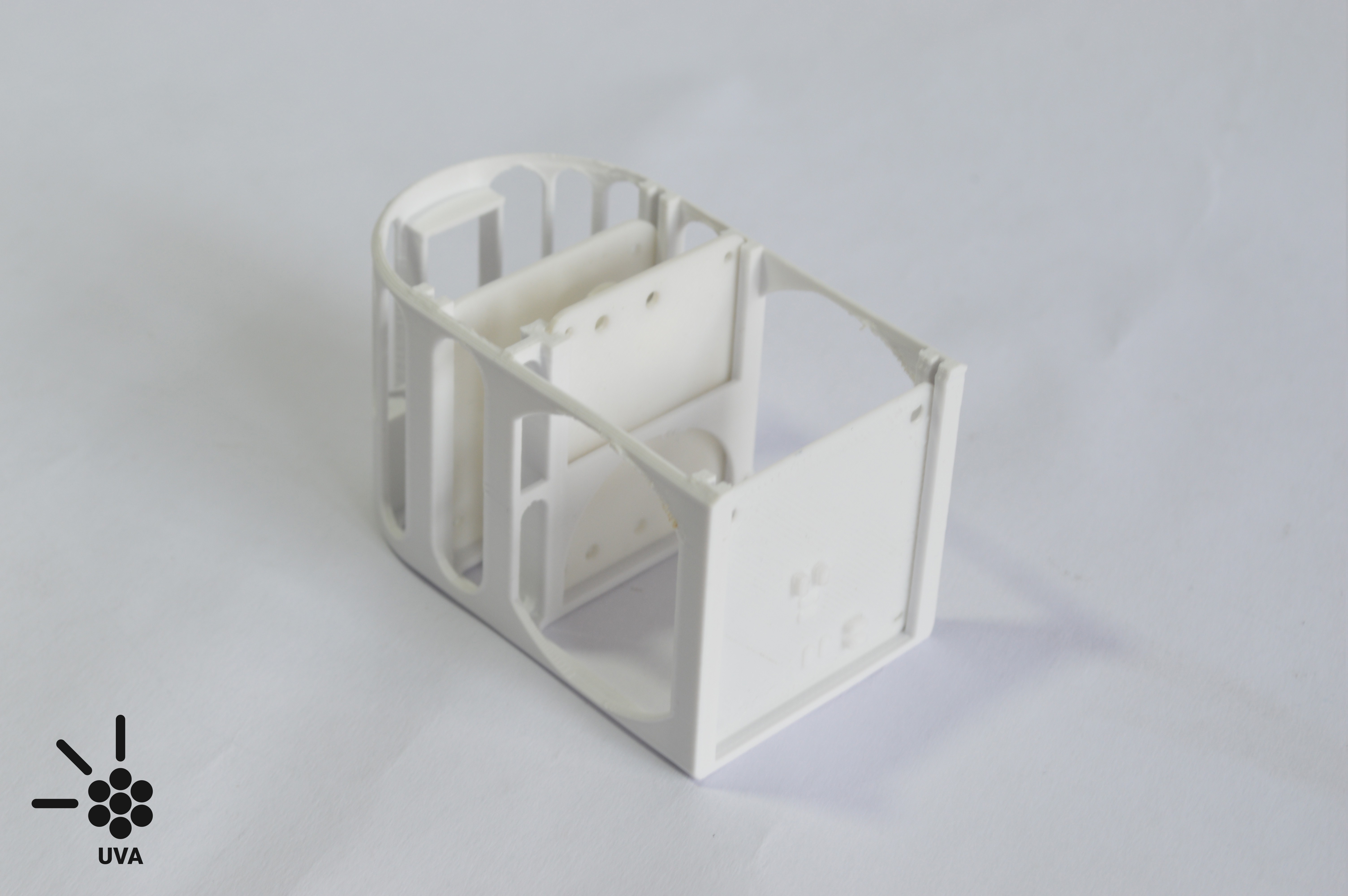

About the design. Like the battery, the UVA head is a modular design that consists of four 3D printed parts (The Chassis, the button, the front closure, and the circuits rack). Every circuit and component have it place in the rack (the UVA led board, the power source board, the screen, the button, and the CPU board). Also, the Chassis has the space to put Two 3M screws of 15mm long with them nuts to transmit the electricity from the battery to the circuits and are part of the UVA joint.

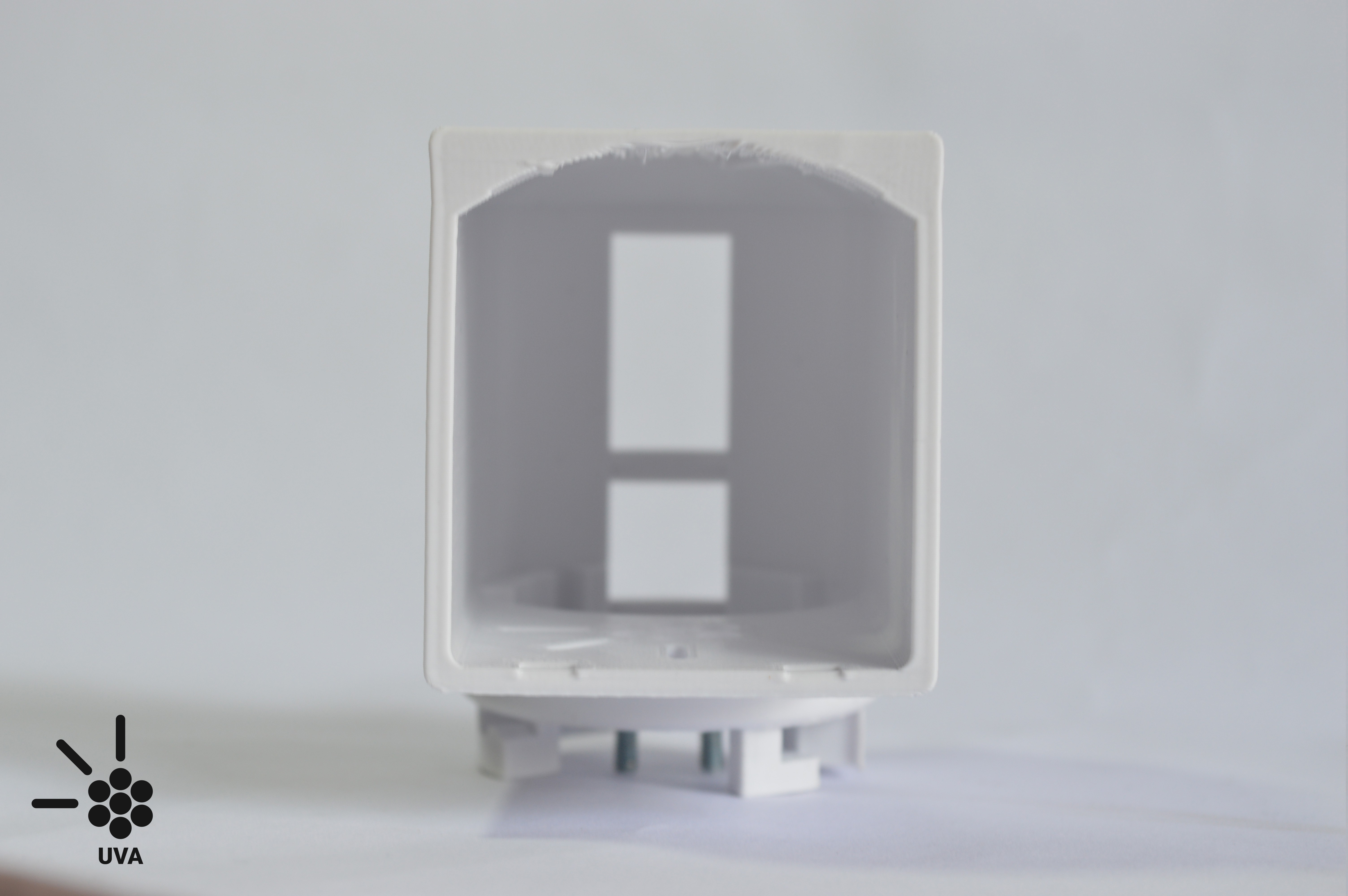

The chassis was designed to be printed without any support insight to facilitate the production and ensemble of the UVA. It was quite difficult and the insight finish of it is not the best but it is a great solution with a segmental arch taken from colonial Spanish architecture. It allows to reduce the height of the arch and keep a reduced size for the UVA head.

Even so, there are some supports outside that you have to manage to remove, but it was not so difficult. Even so, in further prototypes, we would like to reduce more the use of supports.

Al, the rack slices insight into the chassis, and all the connections were designed without glue, only by rotations and pressure. Also, we want to have a one-piece chassis to increase the resistance of it to avoid damages to the electronics and circuits.

Miguel Fernández

Miguel Fernández

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.