Eye candy

Meta

My metaproject here, the real project in some sense, is to get better at writing about stuff like this. My silence lately demonstrates a weakness: reporting unsatisfying progress between tidy milestones. I've often found the work to simplify a complicated thing easier than trying to describe the complications, so instead of writing a lot I've kept working until the writing can focus on the point briefly rather than blur a pile of provisos. I think that trade has often worked well. In this context the habit works against the concept of logging progress and process. So what can I say without either writing a book, or waiting until I get to a point that doesn't require a book to describe, or "simplifying" to an extent that approaches dishonesty, or otherwise offending myself?

Briefly?

I've

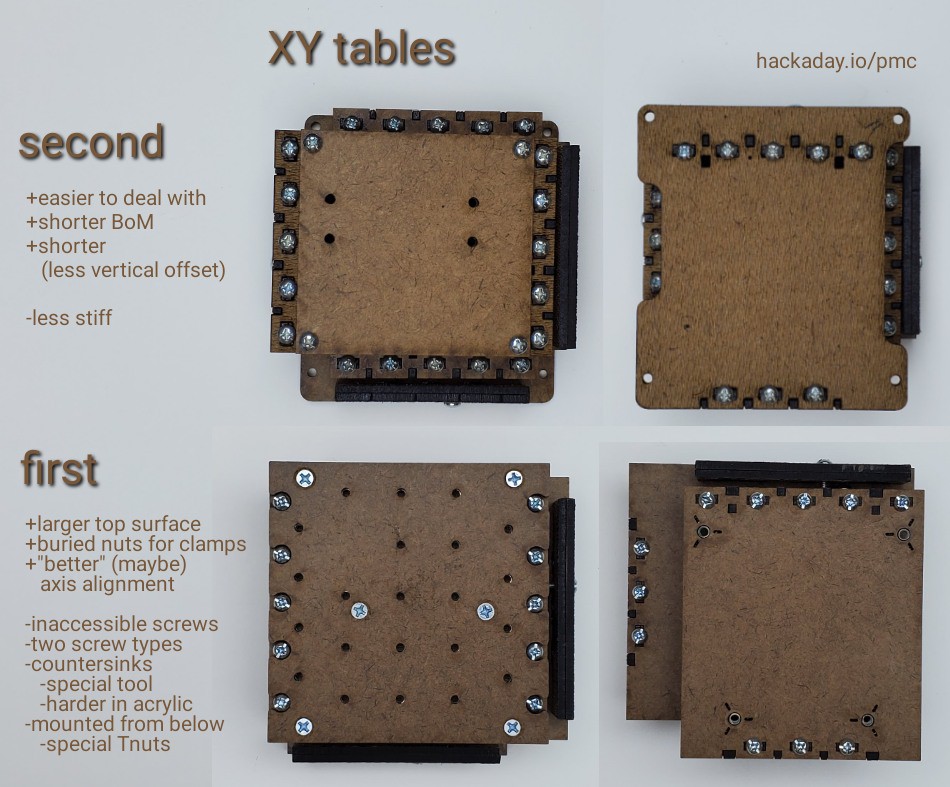

- CADed, cut, built & tested another rev of the axes, that

- simplifies assembly & accessibility

- simplifies backlash adjustment

- includes Dremel-clone spindle mount from laser-cut material and string

- roughs out my test pocket encouragingly well, but with a new imperfection that i don't understand

- has died, in three different ways, at about the same point in the first finishing pass of same test pocket

- Injured, apparently, and maybe crippled, but not entirely killed one of my motors

- it's complicated

- how much time to spend on figuring that out?

- ordered more

- gonna take a while

- which illustrates another element of supply risk

- already noted price hike in "Details"

- Mostly CADed the next rev including

- minor design tweaks

- major CAD refactoring - for eventual sharing

- Deferred writing logs

[...writing down a rabbit hole to discover the point & discard the detail -- a process that works but absorbs time...]

I've been working this project with some urgency because I expect life to interfere "soon", but i don't know when or for how long, and i hope to get a useful increment of progress before this gets shut down for a while. And Instructables has a relevant contest open for what has now diminished to a few more days.

So maybe-losing a motor and almost-but-not getting timely replacement combines poorly with my expectations for the future. Aggravated by several simultaneous uncertainties. So, it's complicated.

Anyhow... after handling the second design some, I've been working on a next revision that I aspire to cut today. But right now I'm writing this instead of working on that, so, see the meta? While design changes are small, I've put time into refactoring the CAD to better suit eventually sharing that - but still leaving "opportunity" to put more time into learning better ways to do things in Onshape.

Direction

Lately in this project I've concentrated on simplification for reproducibility from laser cut material & a simple BoM. At lowest cost, assuming "free" laser cutting.

The first rev was tricky & tedious to assemble and required lots of dis/reassembly to work on. Some tricky/tediousity is baked into the design, but at least exposing all the screws will allow random access vs sequential access into the layers.

At this point I'm focusing on simplification of "user experience" and accepting some compromise to capability. In the current design there are

- no screws buried under other parts

- almost, and maybe zero soon

- except for attaching the motor units, which are very interior

- no counter-sinks

- one less tool

- one kind of screw

- for structure - different screw for motors

- 6-32x1/4 "PC case" screws

- commonly scavengable

- but need many so probably a purchase item anyhow

- better for building with acrylic

- greatly improved backlash adjusters - yay

- fewer large-area parts

- area (not shape) of latest cut job would fit within a Ponoko P2 sheet (384mm*384mm)

- but that's not a feature claim yet

- [is] mount for Dremel-clone spindle - reduces add'l BoM to: string

(design feature list overlaps personal accomplishment list -- janky redundancy but I'll say that's ok for a progress log)

Beyond stating these topics, I will skip over:

- single->double->single->? progression of horizontal plates

- horizontal position of Y with respect to X

- motor mount screws

- 1/4 vs 3/8 inch screws

Paul McClay

Paul McClay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.