While testing today, I figured out that the HF Start loaded the rectifier capacitor, even when I put a MOV or capacitor in parallel. That caused a decrease in arc strenght and after loading the capacitor to a certain voltage an high power discharge on the tungsten electrode.

I tested it again with nothing but the HF Start coupling coil connected to the rectifier and its capacitor still gets loaded, so it is definitely caused by the HF Starter.

By connecting a capacitor in parallel together with the 400ohm resistor in series to the rectifier + reducing the electrode to workpiece distance, I could reduce the loading of the rectifier capacitor to a minimum. Thanks to @Bharbour for the great advice.

The next problem was that as soon as there was a voltage from the welding source on the welding lines (open circuit), what also included a charged rectifier capacitor, the HF Starter arc did no longer work for some reason.

But at the end I was able to get it to work with a simple workaround - Maybe no permanent solution, but for now it's good because it works.

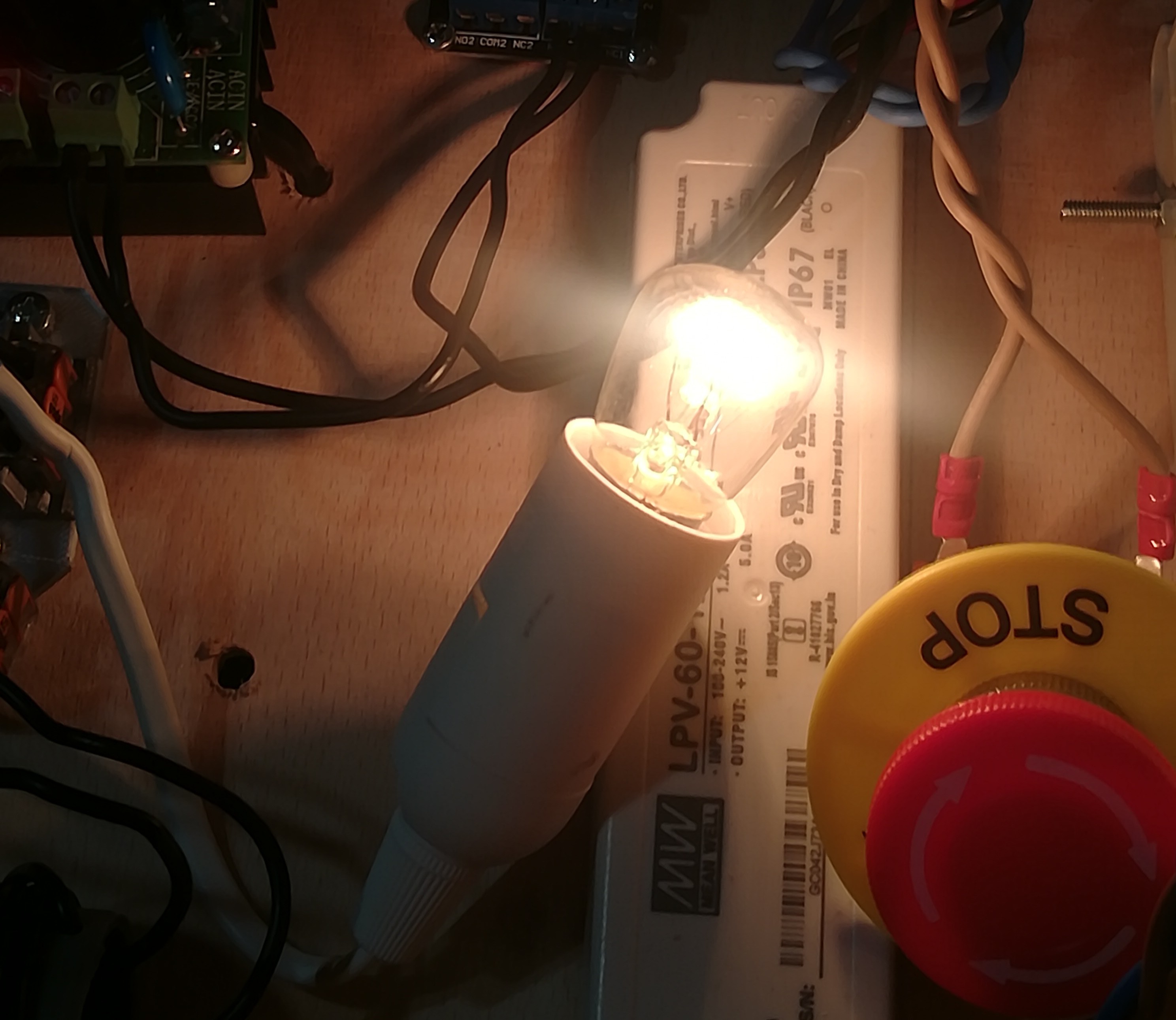

I added a 15W lightbulp as load to the rectifier to discharge its capacitor as soon as there is no longer power from the welding source, what starts the HF arc again. The lightbulp also indicates that there is power from the welding source on the lines what is also a good thing, so maybe I will keep it.

I think there will be a lot to do in terms of emi/rfi protection, what could end up to be really complicated. I will try many things out and hope that I can find a solution for it over the time.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.