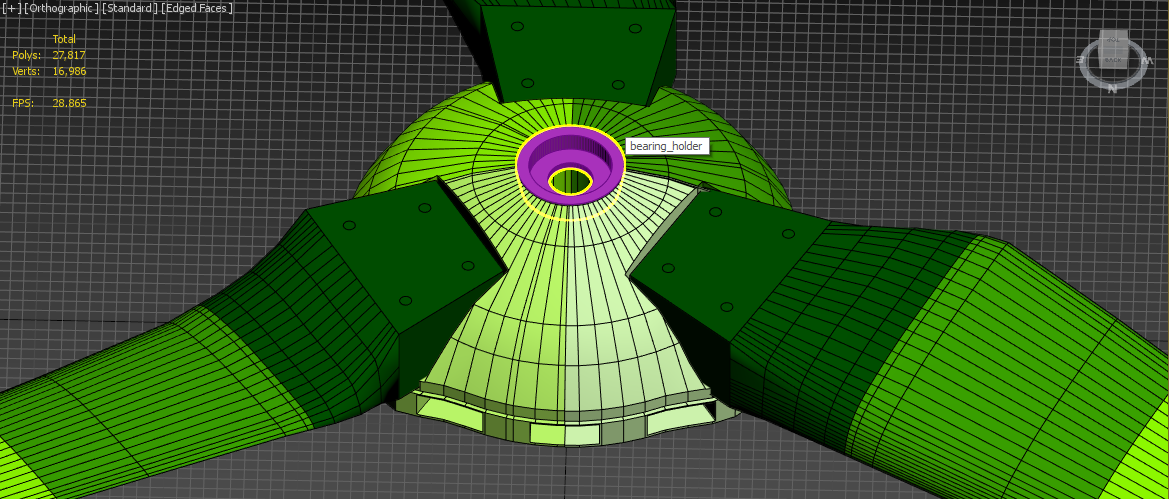

For now we had a little play on the margin between the bearing and the generator. The reason for this is that diameter of the hole for the bearing can vary a few tenths of a mm, depending on how much glue is used. Therefore we designed a custom piece that can be printed in one part so that it always will fit perfectly. It is shown below in purple:

And afterwards both are welded into the generator. It's also possible and maybe even better to wait to insert the bearing until the holder has been welded into the generator:

Bram Peirs @ FW2W

Bram Peirs @ FW2W

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.