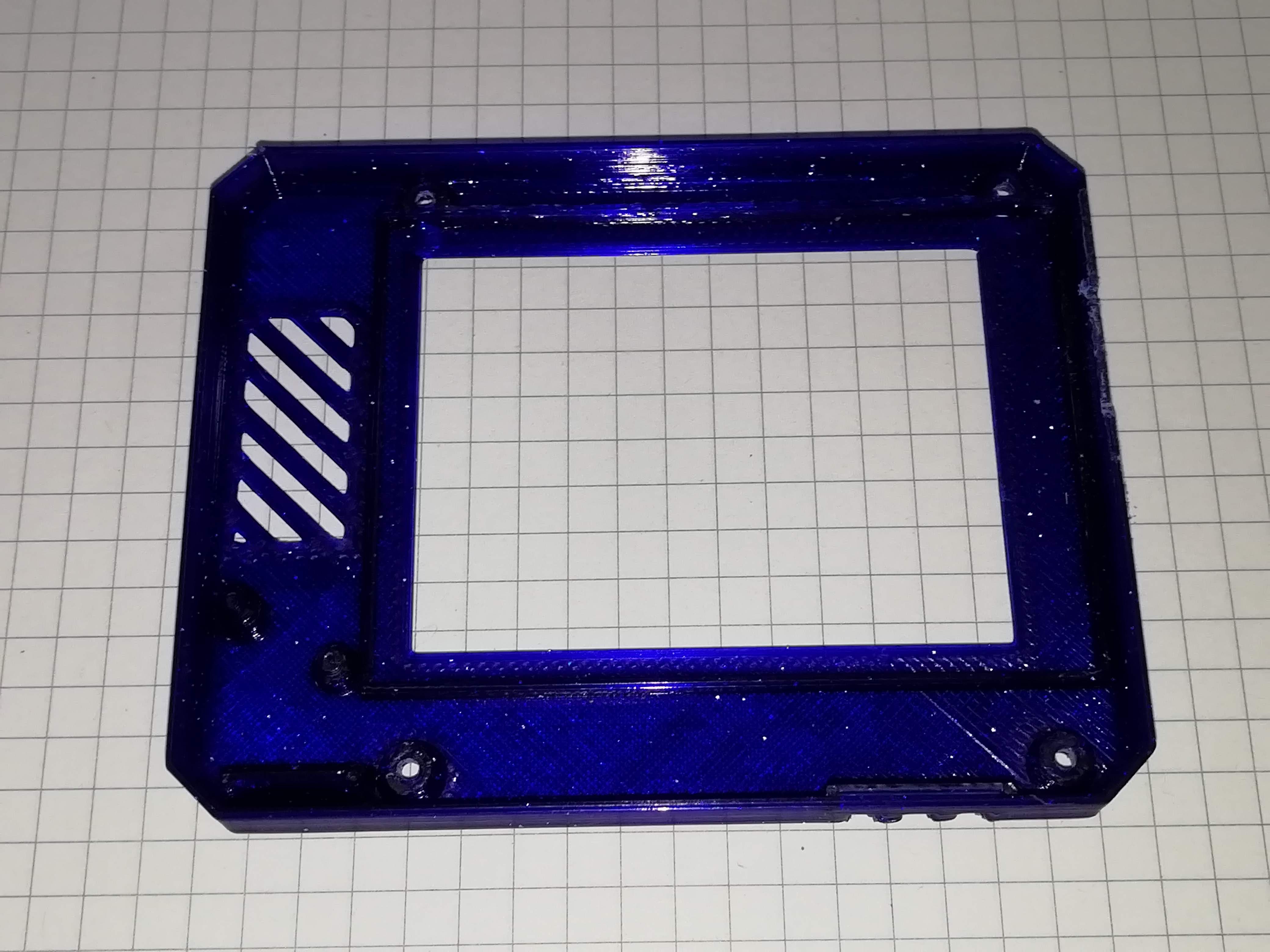

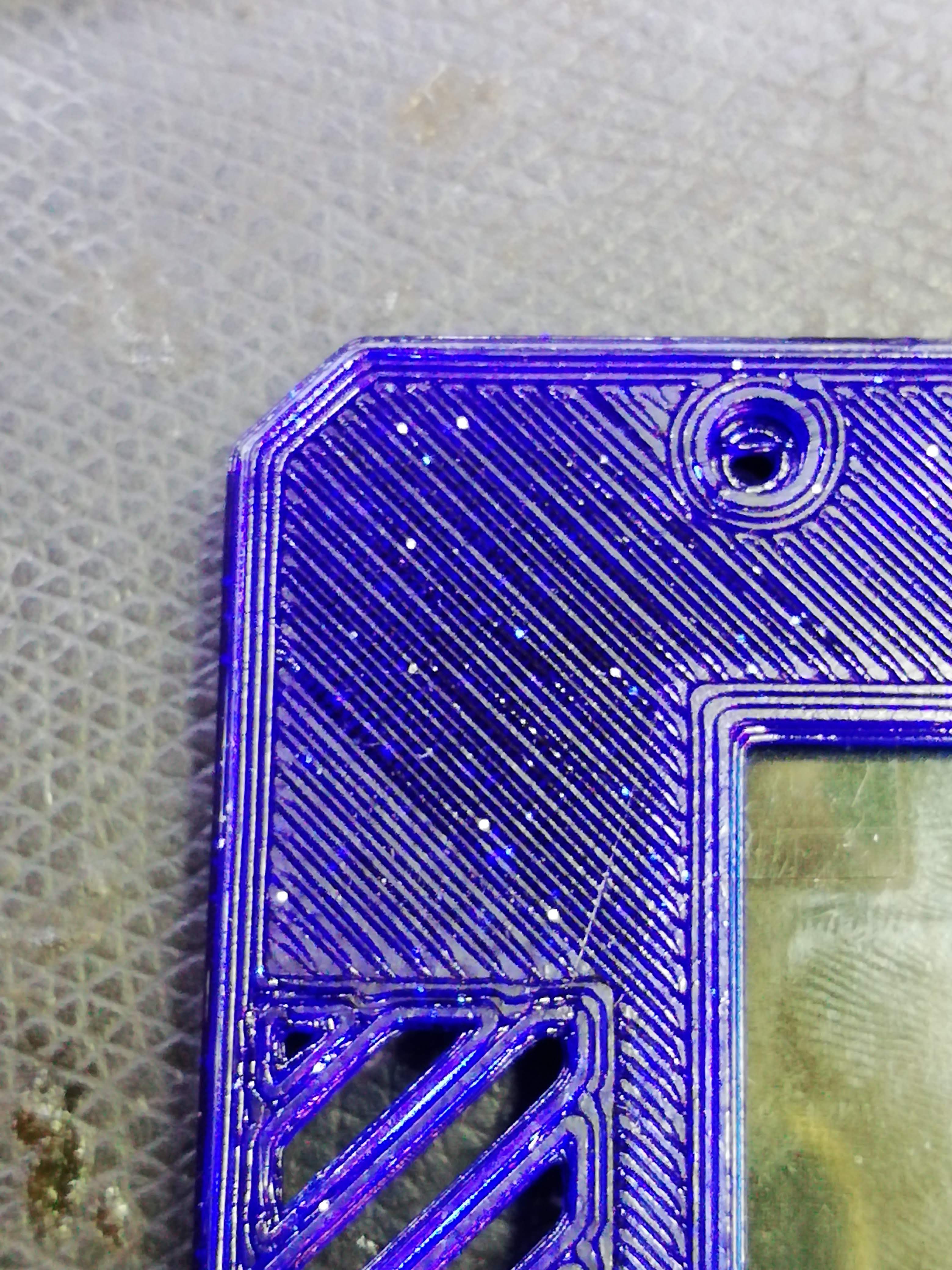

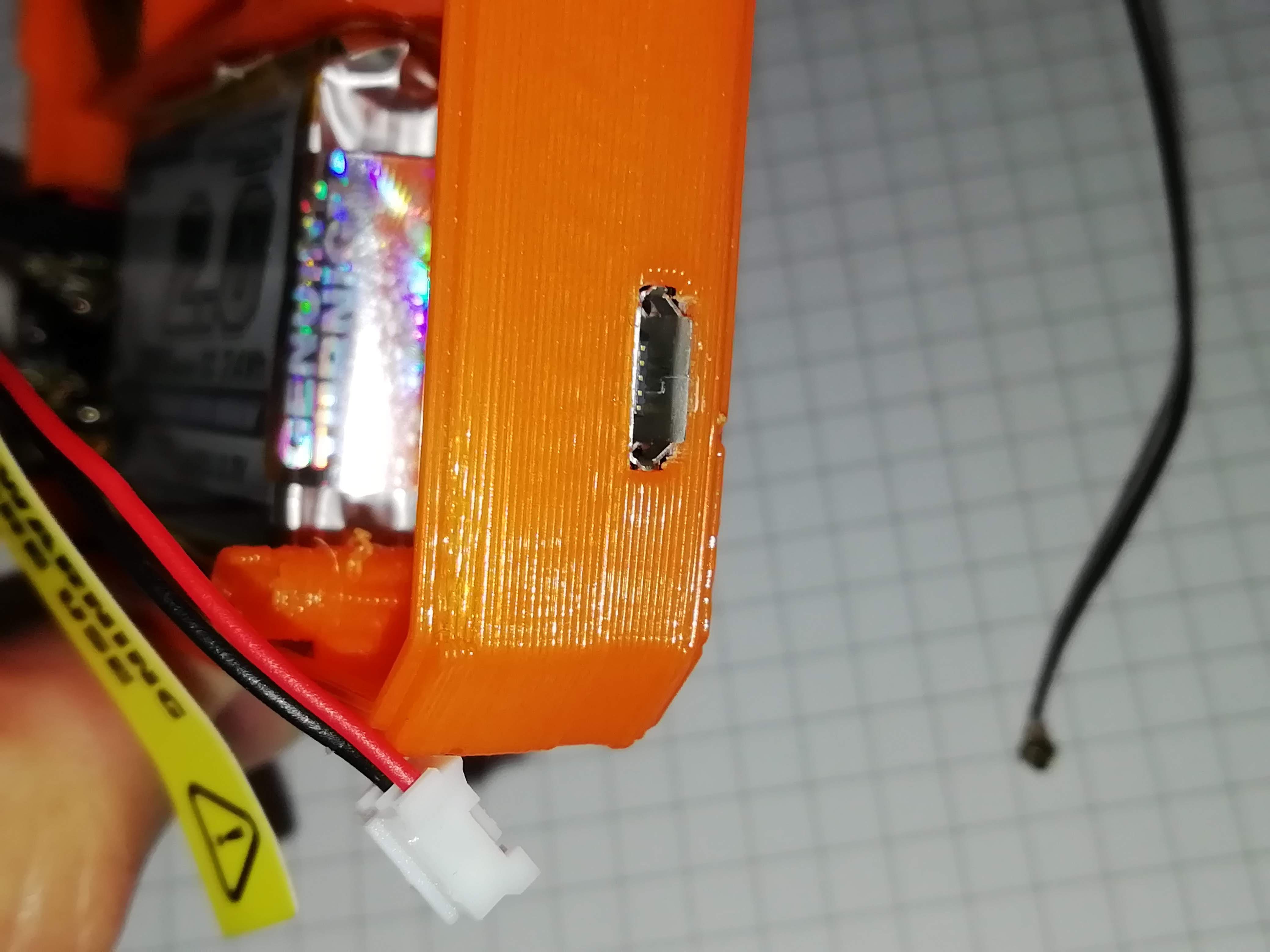

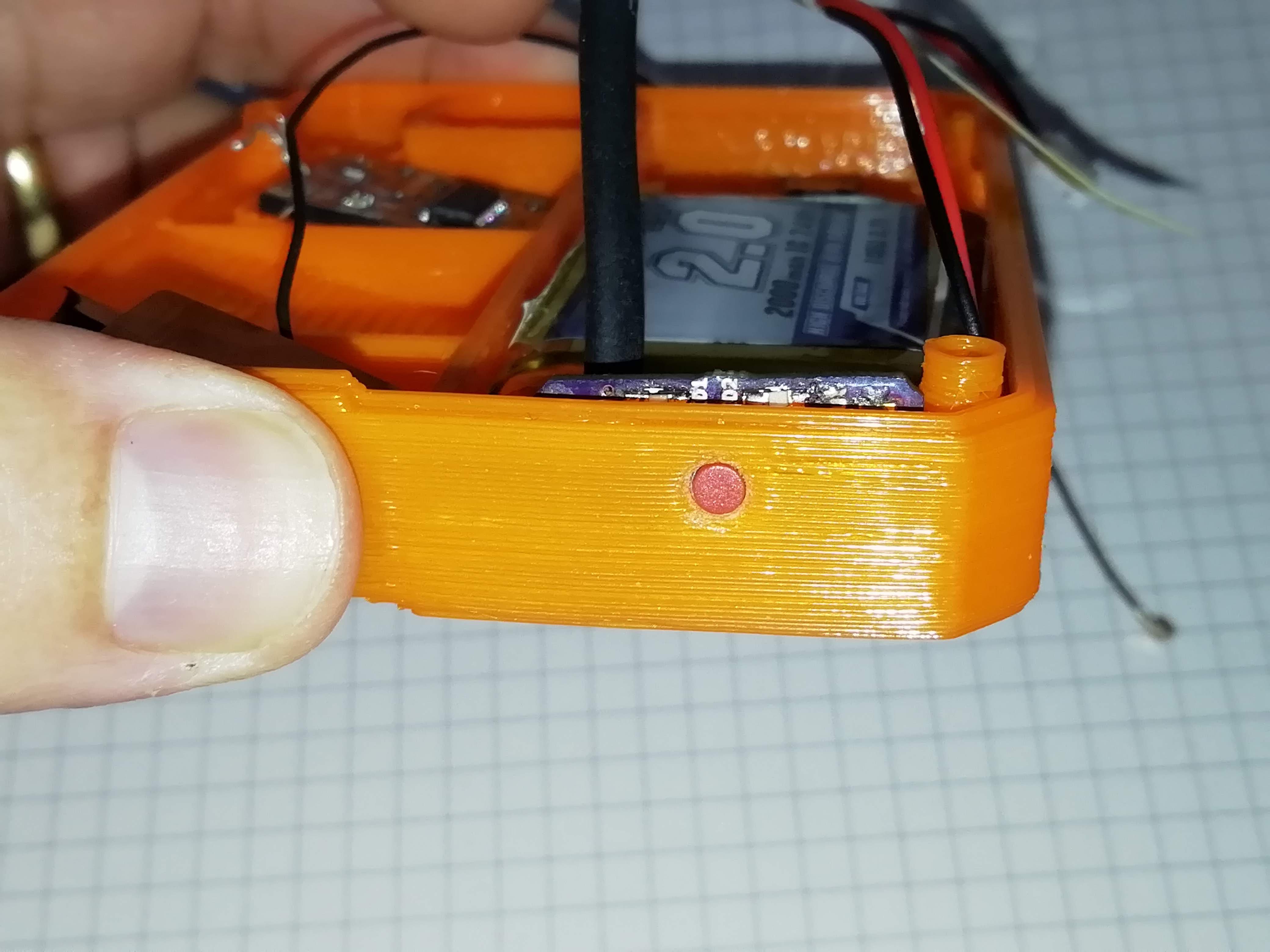

In order to check the validity of my CAD modelling, I made a few low-detail 3D prints of the parts. There are various parts which have a built in tolerance adjustment that can be changed for either FDM or resin printing (important as the final part was to be able to be resin printed in the event that it won.) This was just set as a tolerance parameter and for FDM I used Noe Ruiz's recommendation of 0.2mm for FDM.

Looks like a great fit but one of the sides was 1mm off so could be easily corrected in CAD

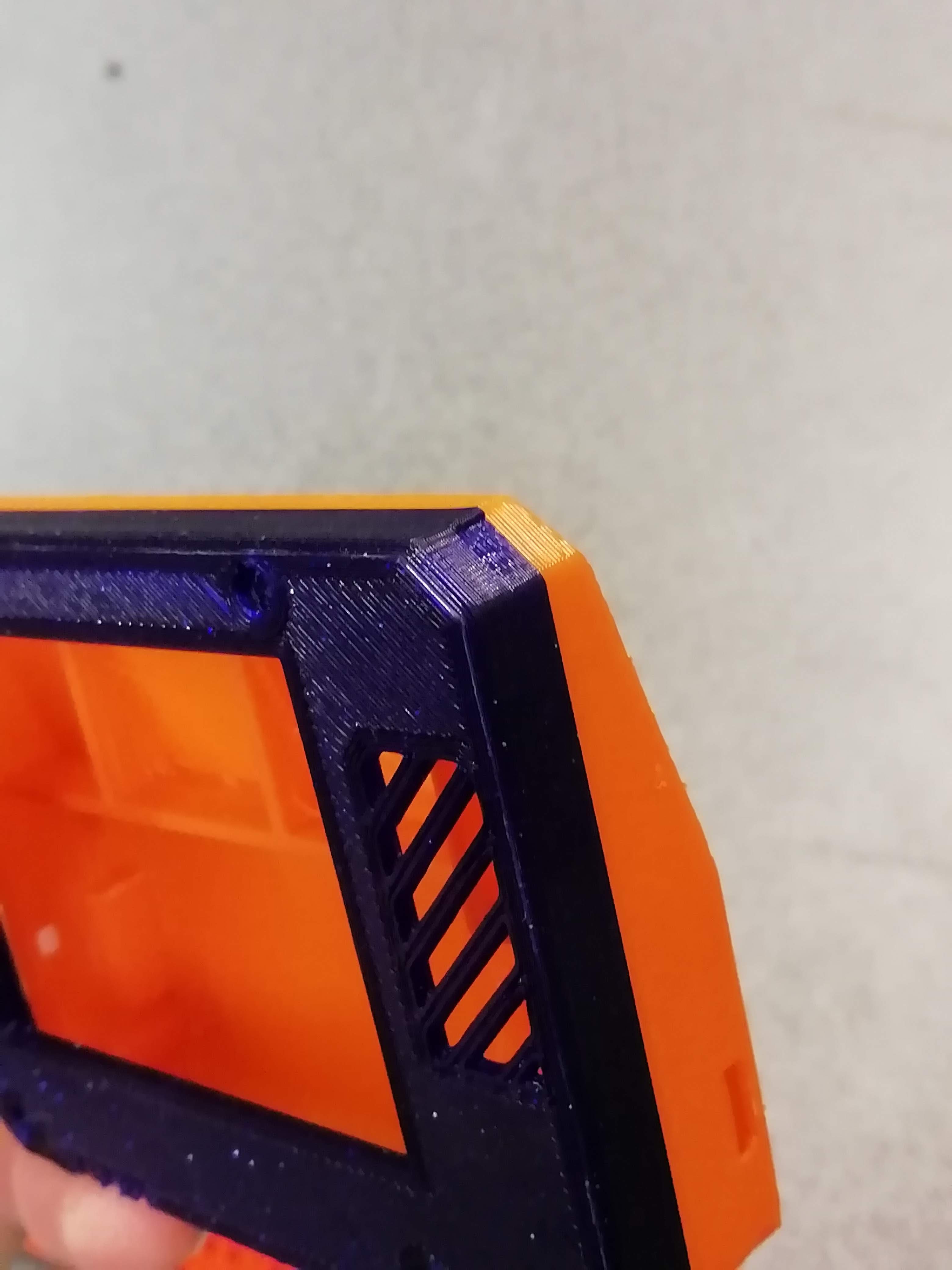

The colours are't final, just what was loaded up, but dayum! that sparkly blue...

I'll take that as a first pass!

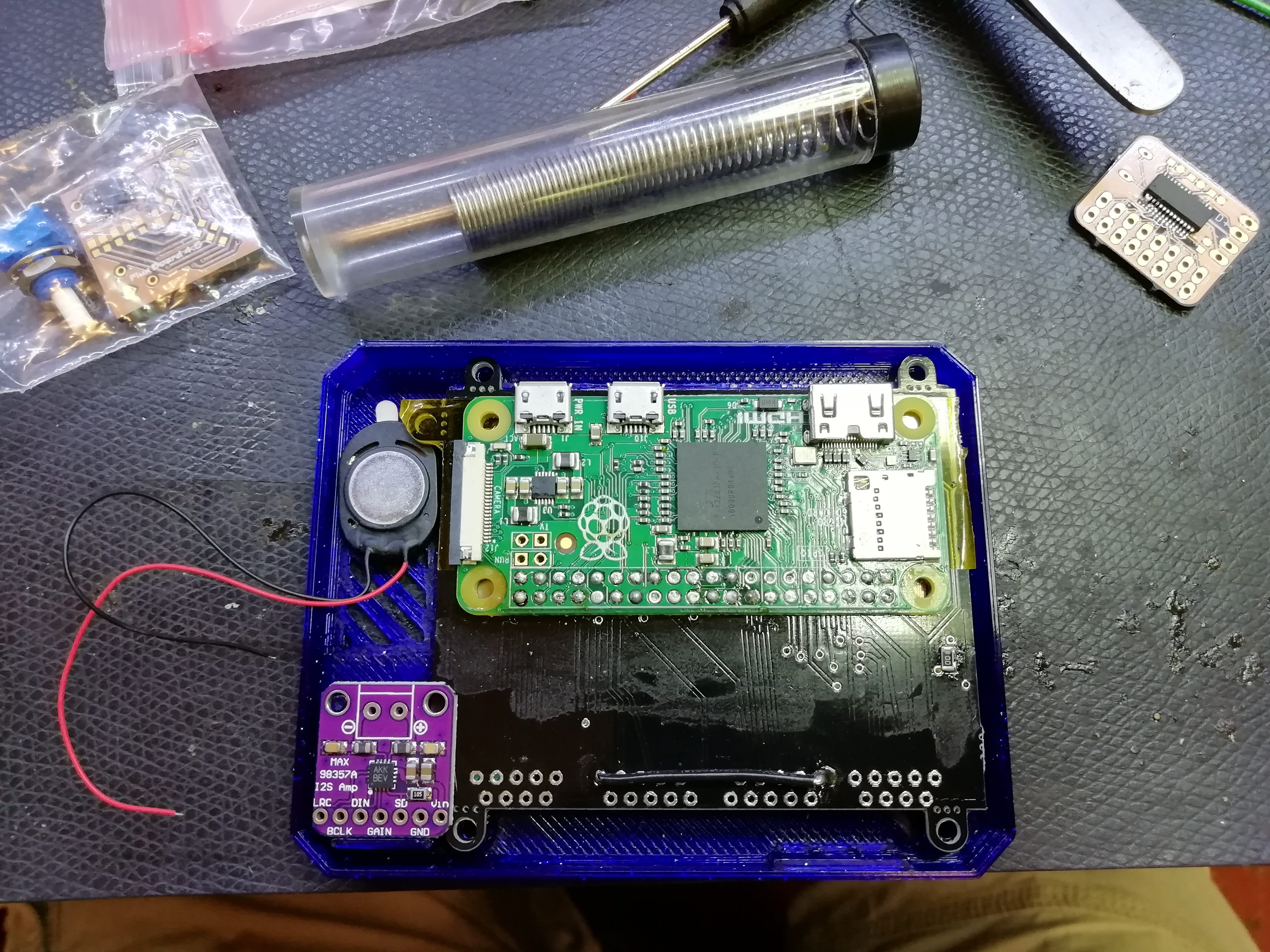

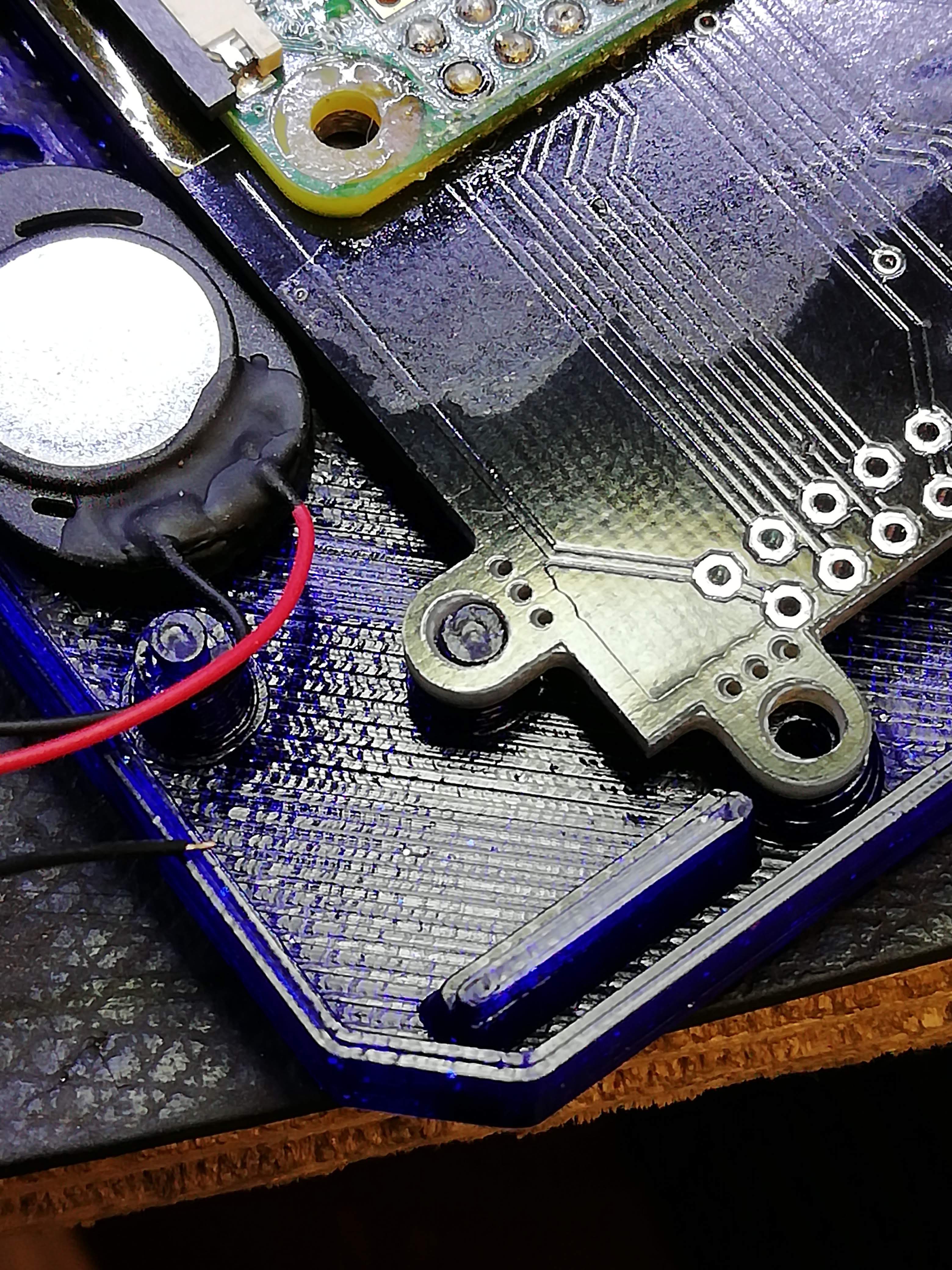

And for the rear case:

All looks really good!

And fits together well too! There are a few minor changes to make but that's why we make test prints...

ABrugsch

ABrugsch

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.