The main documentation for the project is contained in the README Markdown file at the GitHub repo, here is a direct link: GitHub README.md .

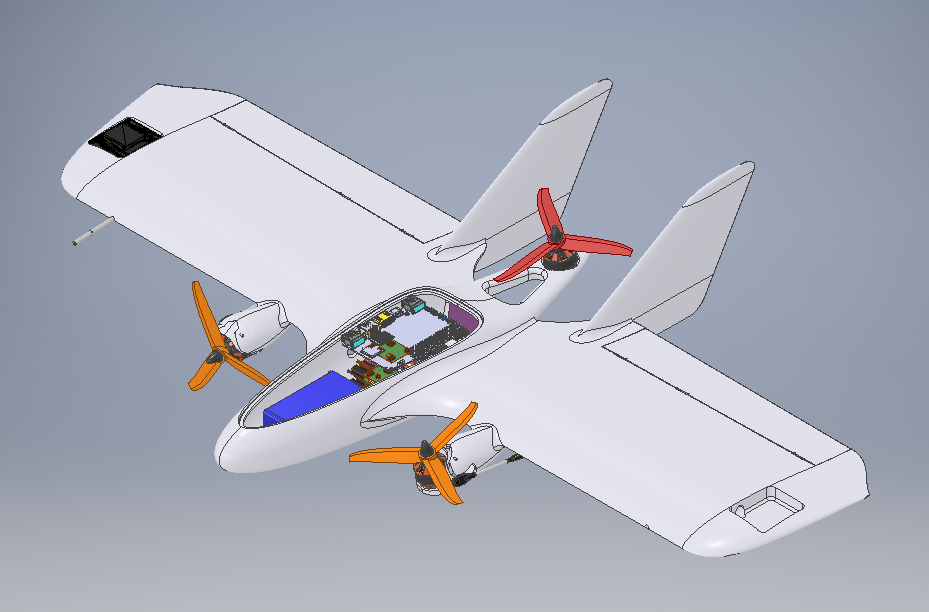

Metrics

| Description | Value |

| Wing Span | 800mm |

| Wing Area | 15.6dm^2 |

| Aspect Ratio | 4.1 |

| Airfoil (Root and Tip) | MH45 |

| Length | 520mm |

| Rotor Spacing | 315mm Circle |

| Lipoly Battery | 4s, 1300-1500mAh (~160g) |

| Motors (front) | 22xx or 23xx 2300-2600kV |

| Motor (rear) | 22xx or 23xx ~2000kV |

| Servos | HS-65HB/MG or eqv. |

| Flight Controller (size) | 30.50mm to 16.0mm Grid |

| Propellers (front) | 5050 to ~5249 |

| Propeller (rear) | 6030 to ~5249 |

Steve Carlson

Steve Carlson

Hákon Hjaltalín

Hákon Hjaltalín

Alessio Fabrizio

Alessio Fabrizio

Peter Sinclair

Peter Sinclair

Hi all. Exciting project this. Would it work with 5” motors and props? Parts are expensive nowadays but 5” freestyle drones are 2 a penny on the second hand market. I reckon with the right flight controller (F405 or similar) you could use it as a parts repository. I’ve seen some 2204 cinewhoops which might fit the bill. Guess I’d just need to work out a total thrust requirement and run it through eCalc,