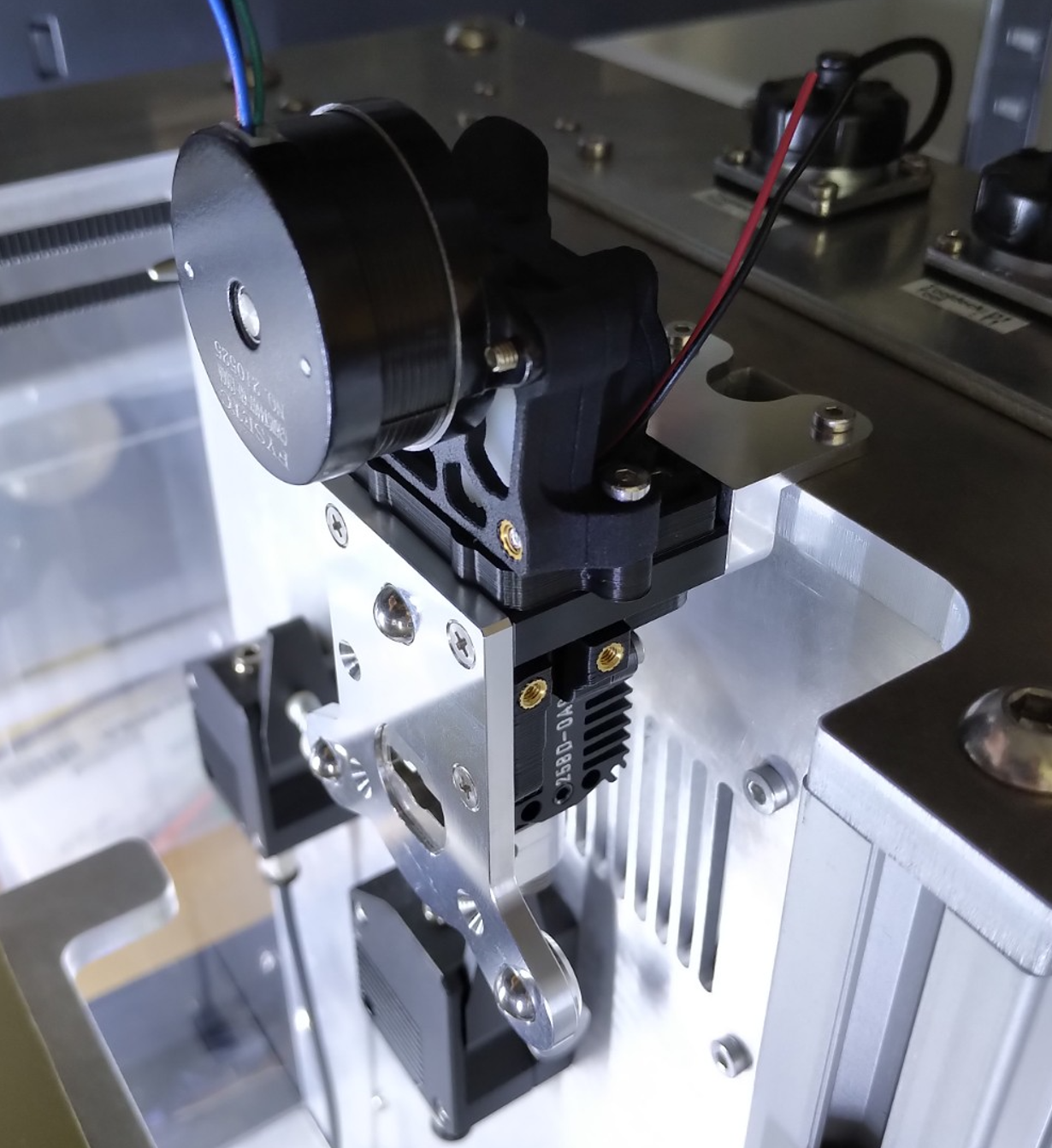

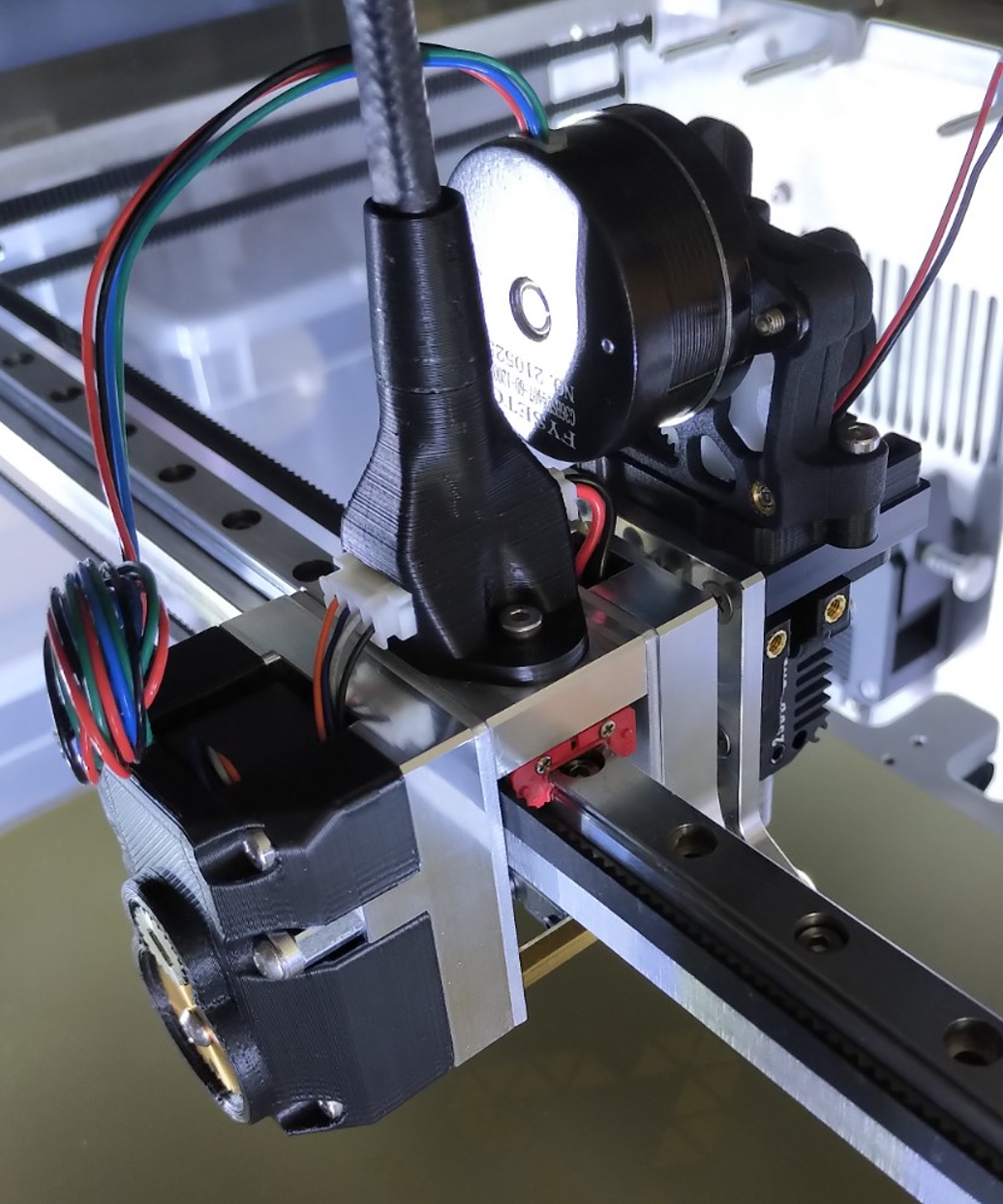

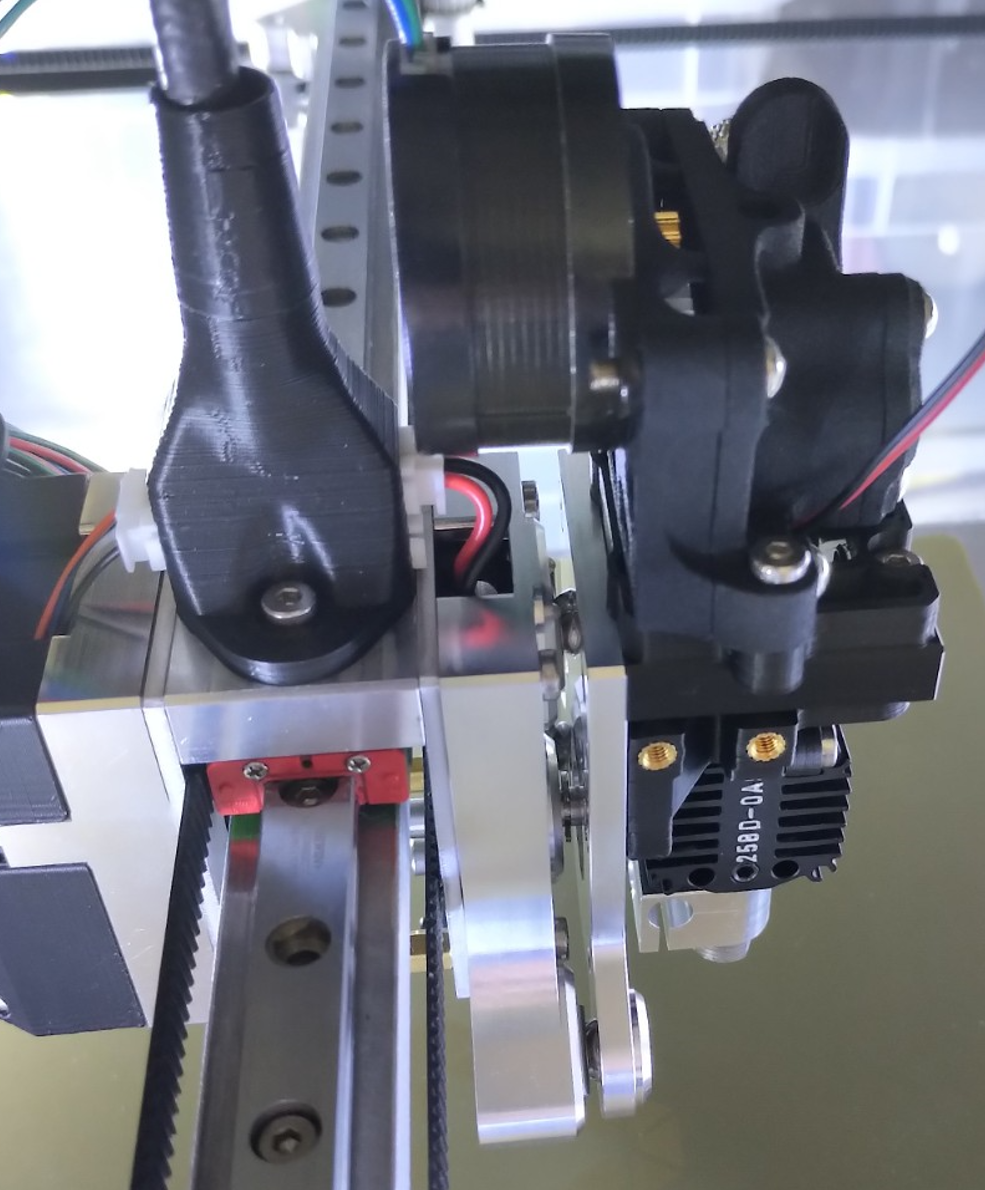

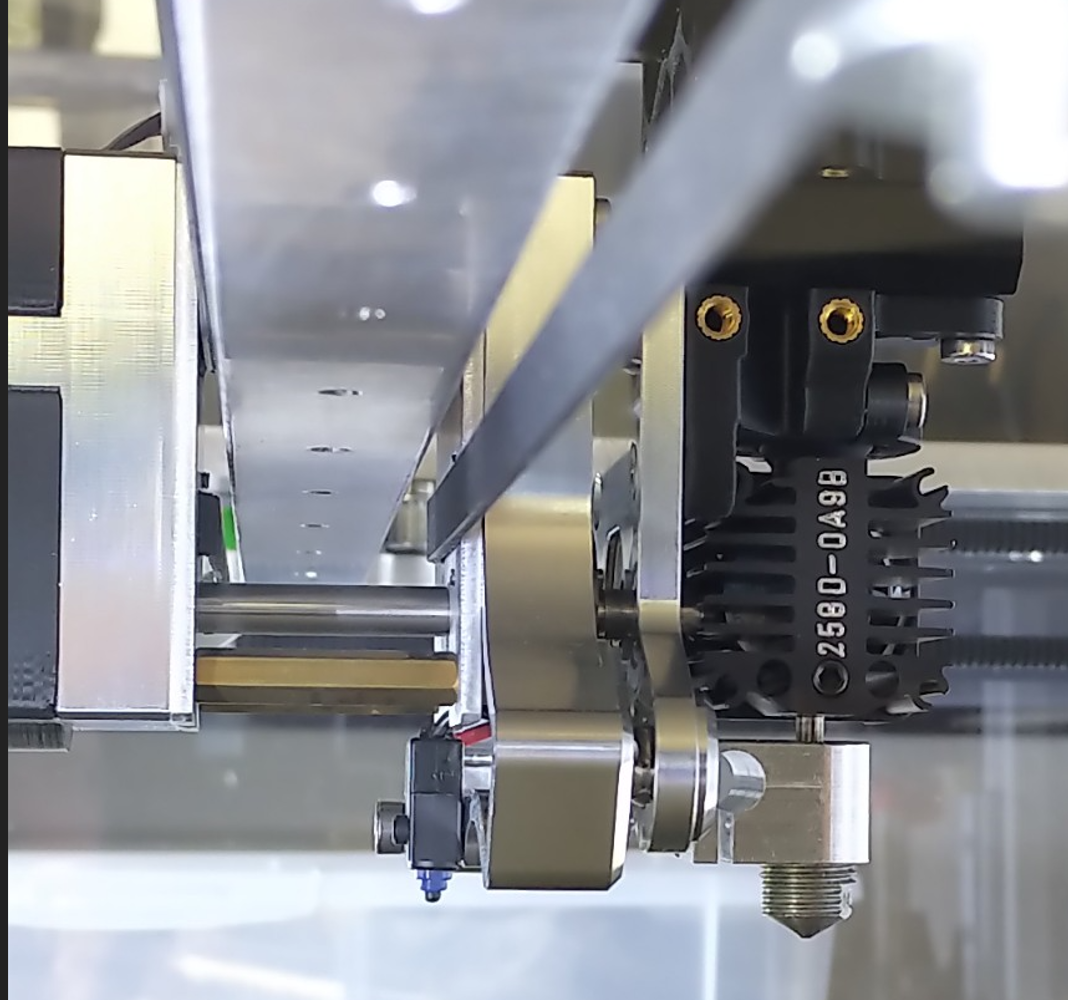

I've continued the build process of the directdrive toolhead with a sherpa mini extruder and a Dyzend-Hotend (Allmetal).

I've designed the tool around the common E3D-Toolplate so maybe someone with a genuine E3D-Toolchanger can use this directdrive tool as well.

All the files are here:

https://www.thingiverse.com/thing:4921544

Preparation:

Because of the compact design the Dyzend needs some adjustments to work with the coupler. I've wanted the center of mass of the printhead as close as possible to the actual toolhead to minimize the leverage and therefore the play of the tool due to tolerances in the carriage (X-Axis)

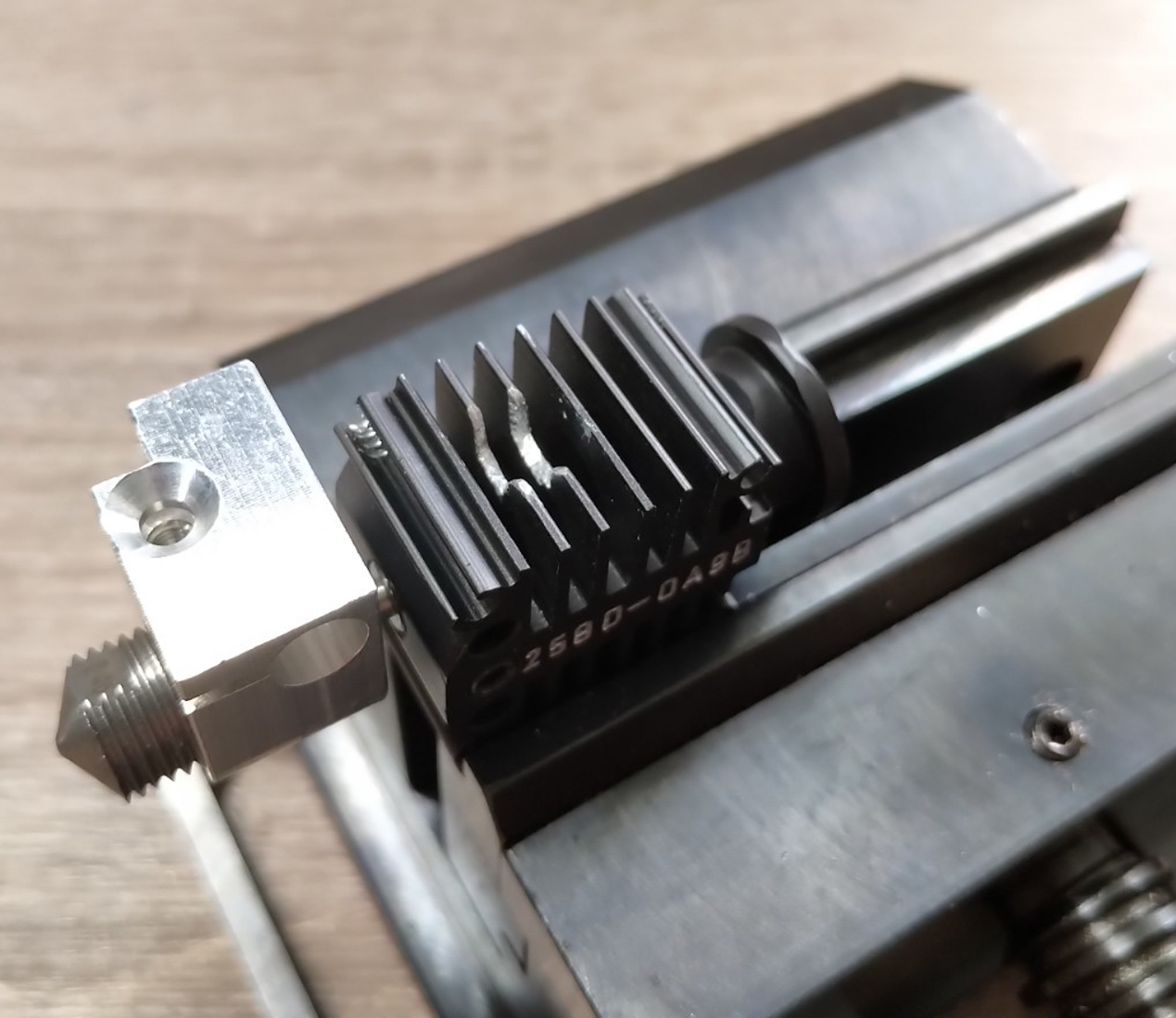

I did a small cutout/drillout for the coupling mechanism of the toolhead otherwise the coupling would not work. Because I didn't want to drive to my cnc mill I've quickly used a ø5mm drillbit and a file to make it work.

I did a small cutout/drillout for the coupling mechanism of the toolhead otherwise the coupling would not work. Because I didn't want to drive to my cnc mill I've quickly used a ø5mm drillbit and a file to make it work.

Simon Wirz

Simon Wirz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.