I have been thinking a lot about my dust separator and trying to visualize how it all works. I decided to do a writeup on my belief, and hopefully someone smarter than me can point out the flaws in my thinking.

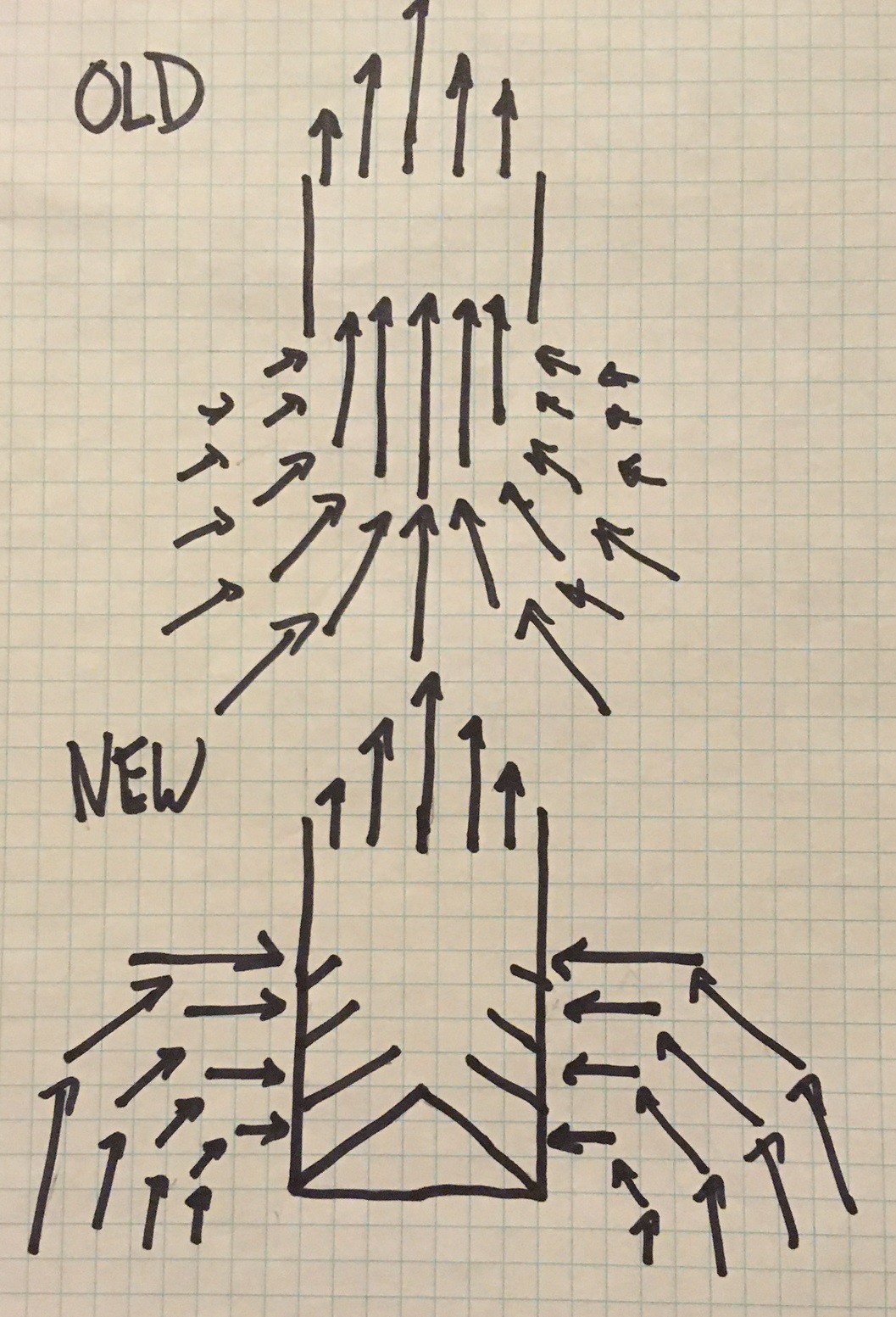

For starters the Thien separator, why does it work (or does it work at all). There are two ways to look at this one. The first is that somehow the particles enter the chamber, spin around the wall and slowly drop, that much is true. Then the Thien baffle would act as a knife blade, separating the dropped particles from the return air flow. However I don't think this is a valid way to look at it, in fact I suspect the small tab on the separator is not essential for this to work (whether or not it has a small benefit). Rather my thought is that the separator is reducing the speed of the return air by spreading the flow over a very broad area before allowing it to drop into the bucket. The idea in my head is that there is a concentrated flow of suction near the return nozzle and if the sawdust piled up high enough in the bucket then this stronger suction would be able to pick up particles and send them on to the shop-vac. The separator forces the air to spread out and that in turn causes a reduction in suction near the edge of the baffle that allows the sawdust to rise much higher in the bucket before getting sucked into the shop-vac. I suspect that a much smaller diameter baffle that was perfectly circular would work just as well.

My idea was if we are just trying to slow down the air, ie divert the suction so it is oriented horizontally rather than vertically, then why not just use a baffle (diffuser?). I created the baffle below with a series of holes that are more and more restricted as you go down in depth. That causes a strong suction at the top of the baffle and a slow suctions at the bottom edge with no suction on the bottom itself (it is fully blocked). That in turn causes a series of air currents that steer the air out sideways from the baffle rather than downward and hopefully that has the same impact as the Thien separator without the added complexity and space of the extra baffle disk.

All of this is independent of what is going on with the inlet side of the separator. On that side particles are thrown into the bucket wall at a high speed and hopefully they loose momentum quickly as they are asked to rapidly change direction and drop out of the air flow. In theory the goal is to keep these two systems separated, hopefully the outlet suction is diffuse enough that it has little to no influence on the inlet vortex.

Anyway I have a lack of sawdust at the moment so I can't effectively test these right now. I may try to test them anyway just to make sure they don't make things worse, but we won't know how good they work till I have 3/4 of a barrel of sawdust to play with. I guess I need to come up with some new ideas on what to make and stop trying to improve my tools.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.