It would be nice to be able to work out the lasers peak power, and to check out how linear the power response is as we lower or raise the input power. The tool we use to do that is a laser calorimeter. This is a device that measures the temperature change on an object from the beam of the laser being shown on it for a fixed amount of time. It is really nothing much more than a regular oven thermometer that has been calibrated accurately. The problem is the simplest ones start at $100 and quickly go up to $500 for fancy ones with digital displays.

The NBS published a nice writeup on how laser calorimeter's work. It is a bit heavy on the math but the ideas are hiding in there if you are patient.

We can still try to make our own calorimeter but it will be uncalibrated and only good for relative measurements. The user Warsky posted an interesting take on a calorimeter on the laser pointer forums. This is basically a piece of tinfoil of a known size that has been painted black and is held a fixed distance from an IR thermometer. You hit it with an unfocused laser for a set amount of time and measure the change in temp. They have some funny math to try and work out the power, but you can ignore that part.

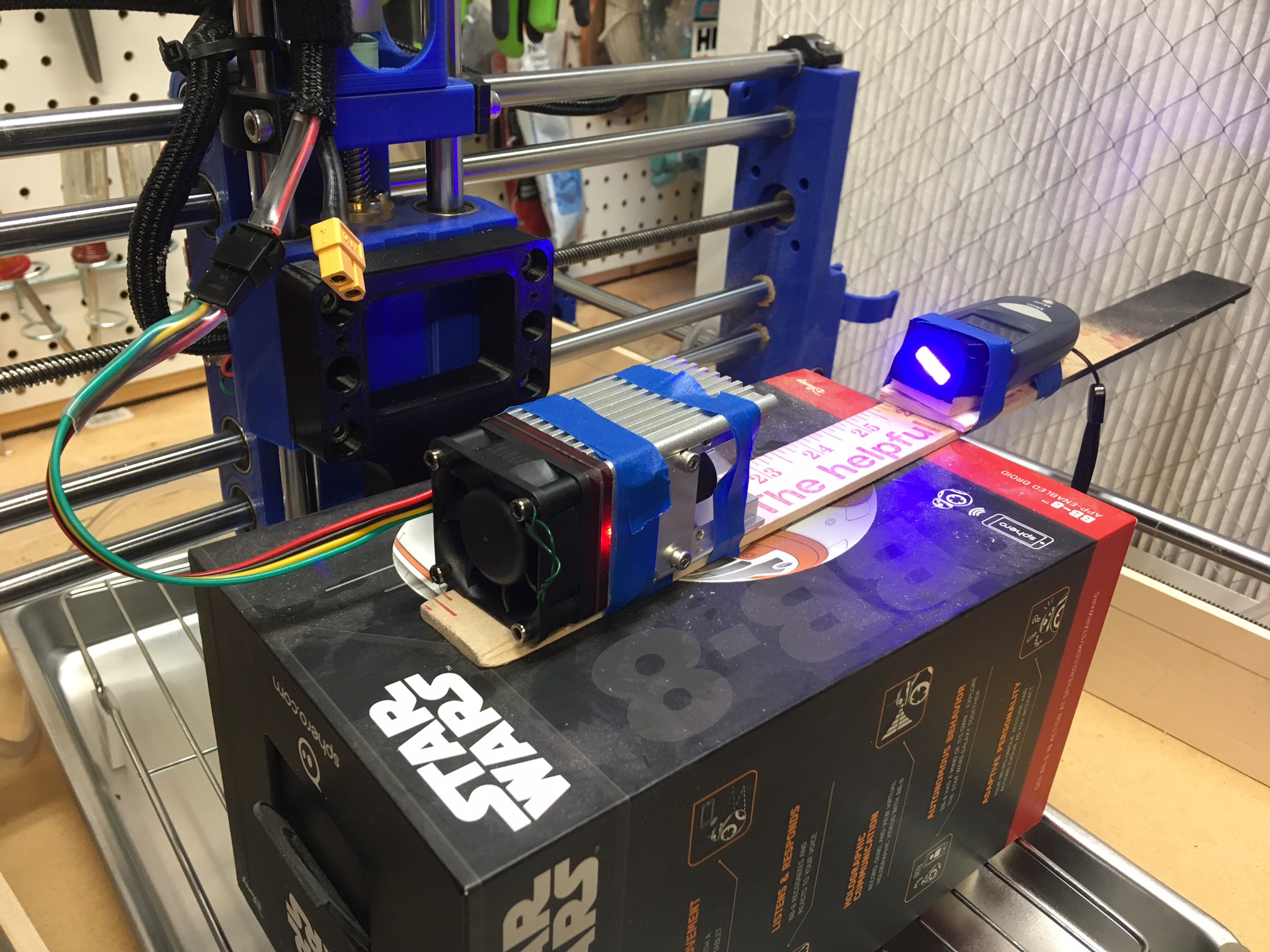

I decided to take there idea and apply 3D printing to the solution. I have a small Cen-Tech IR thermometer from Harbor Freight that can be put into continuous mode. I printed a small holder that slips on the front that can hold a square of foil a fixed distance from the thermometer. The idea is to paint the foil black to increase the absorption of the laser light, shine an unfocused laser at it for a set time and hopefully get a repeatable and linear increase in temperature based on power.

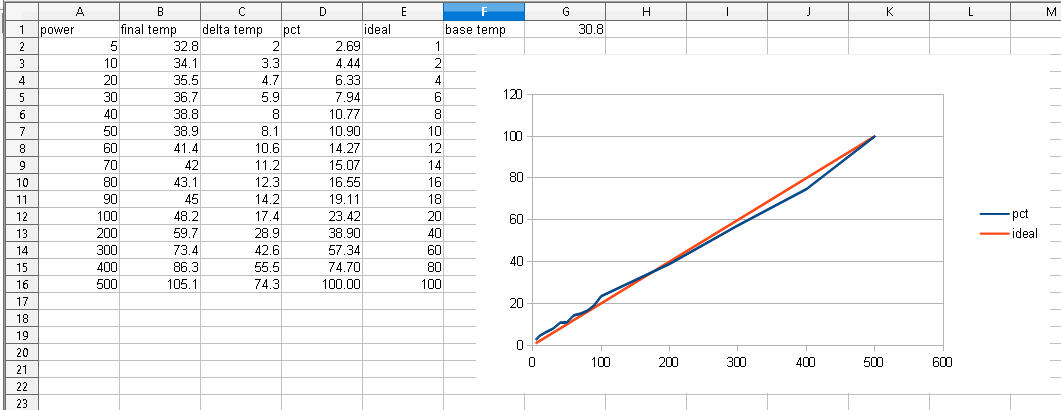

I wrote a simple program that will turn the laser on for a precise amount of time at a fixed power level. Then I ran through a series of power levels and recorded the peak temperature. Unfortunately with a 5 second pulse I was only able to go up to 50% before my IR thermometer maxed out It seems to max out at around 110 C (230F). I was surprised that an unfocused laser can heat the foil that much in 5 seconds. I will try again with a much shorter pulse but that will make it less stable and harder to see the temperature climb on the LCD panel.

Here are my results, you can see for the lower half of the power range the optical power is very linear with respect to the requested power. This is great news, it should make engraving more easy to handle.

Anyway this is working great, even if my laser is a bit too powerful for the test. I need to find a piece of metal with a bit more mass to it, maybe some steel flashing or something. It would also be nice to have a lower power laser to compare against so we can see how the power numbers hold up. Maybe someday...

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.