I have some1/8" (3mm) Baltic birch from woodcraft that I thought I would test cut with the laser today. This is truly 1/8" so it is more like 3.2 mm and is 3 ply.

Anyway I wanted to see how well I could cut it with and without air assist. I did some initial cuts into the side of it at 100-400 mm/min and 75% power with full air, however none of those really made it through. So I tried again at 80% power and speeds of 25-100 mm/min and full air and this time I made it through nicely.

Next I wanted to see how important the air assist is so I ran the job again with no air and then with the air set to a light trickle (just barely making any noise). You can see that no air is a disaster waiting to happen, I don't think you should go near wood with a laser that does not have air assist. Light air faired a bit better but you really need the speed to keep it from burning. Neither cut very deep and the cut has a lot more taper to it.

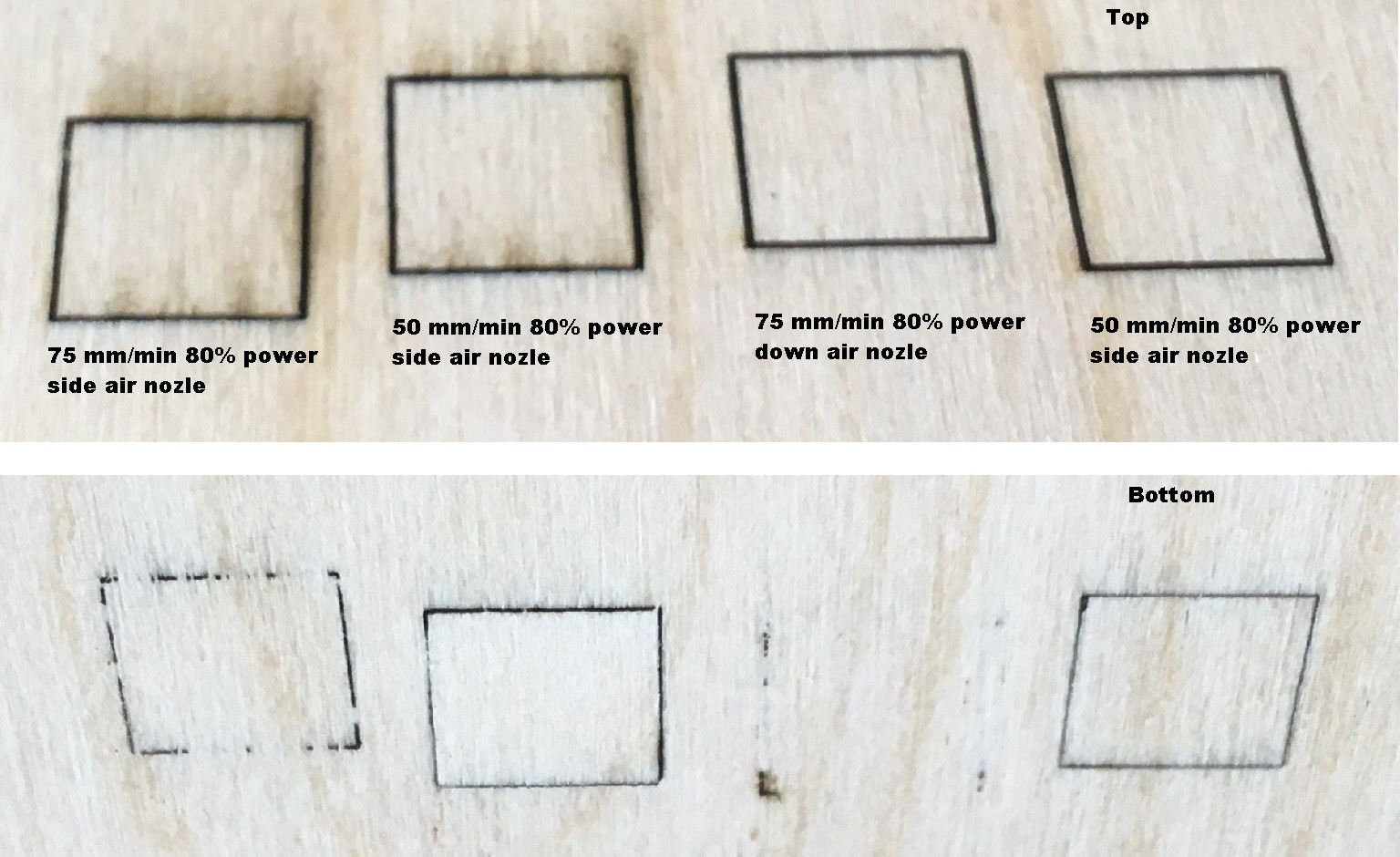

Next I wanted to compare my two air nozzles, the one that is mounted next to the lenses and blows in from the side vs the one that mounts over the lens and blows straight down into the cut. I also wanted to verify what speed would successfully cut through my wood in one pass. It turns out 50 mm/min at 80% power can cut through in one pass. That is not setting any sort of a speed record, but it is not bad.

The side air nozzle is a bit of a dud. It is working way better than no nozzle but it is blowing a lot of smoke across the work in the direction the nozzle is aiming (towards the top of the piece in this case). The downward air nozzle produced less smoke and appeared to have less of a flair up as well. Visually it appears the width of the cut is smaller as well.

I'm still contemplating ways to seal the over the lens nozzle around the lens, I'm not sure if that is worth the effort or not. Maybe it is time for some experimentation. But I will be sticking with the over the lens nozzle going forward. Having a loud compressor run is not as bad as a smoked out cut.

This basically confirms what we already knew. To cut wood you need a lot of air blowing straight down into the cut to clear away all the burnt material. And it highlights another point, this is very much like trying to cut wood with a soldering iron, it is a serious fire hazard and all safety precautions should be followed at all times. Most importantly don't turn your back on the cut, it can flair up really fast.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.