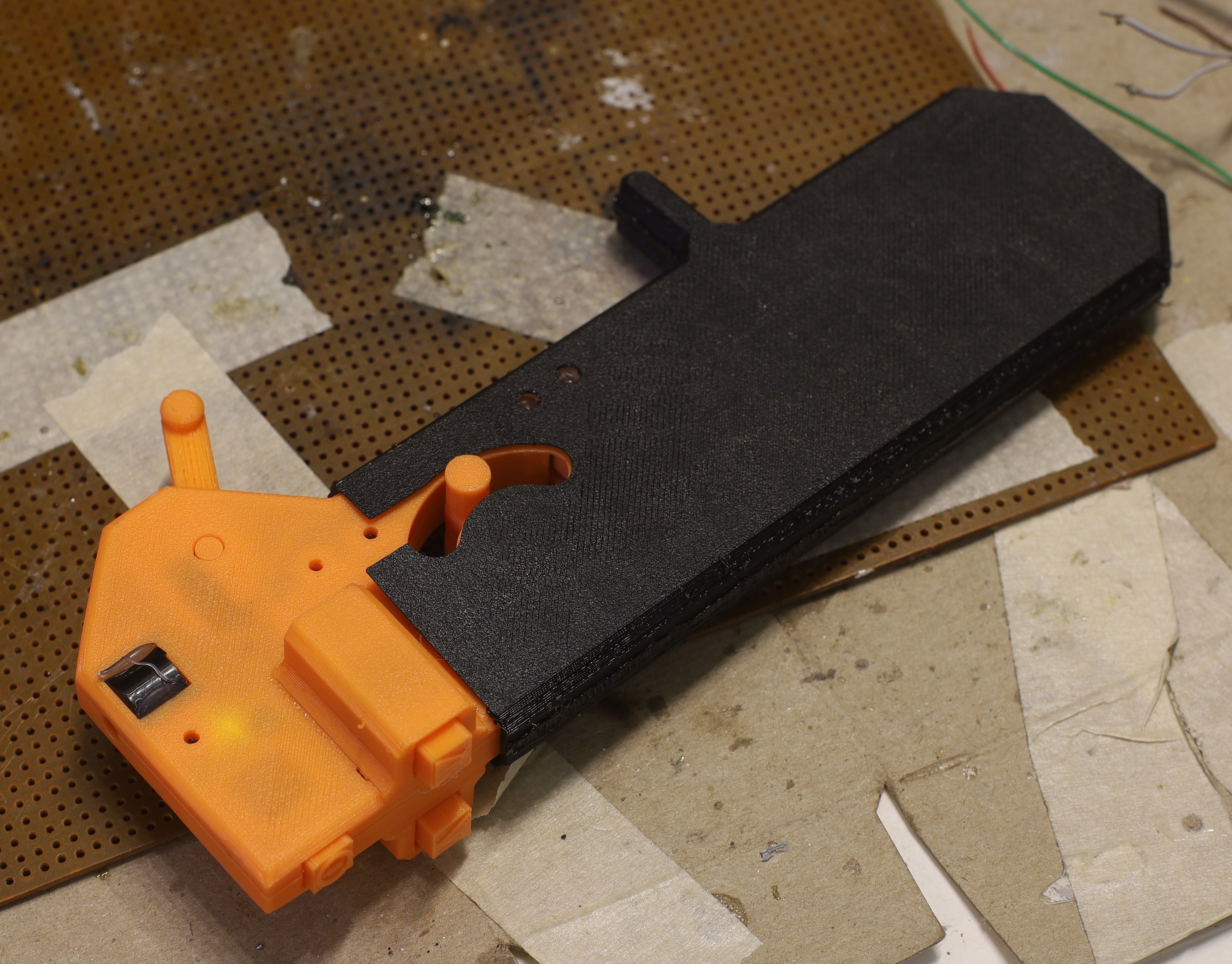

The mane desires in a new remote were improved water resistance & replacing all the hot snot with PLA welding.

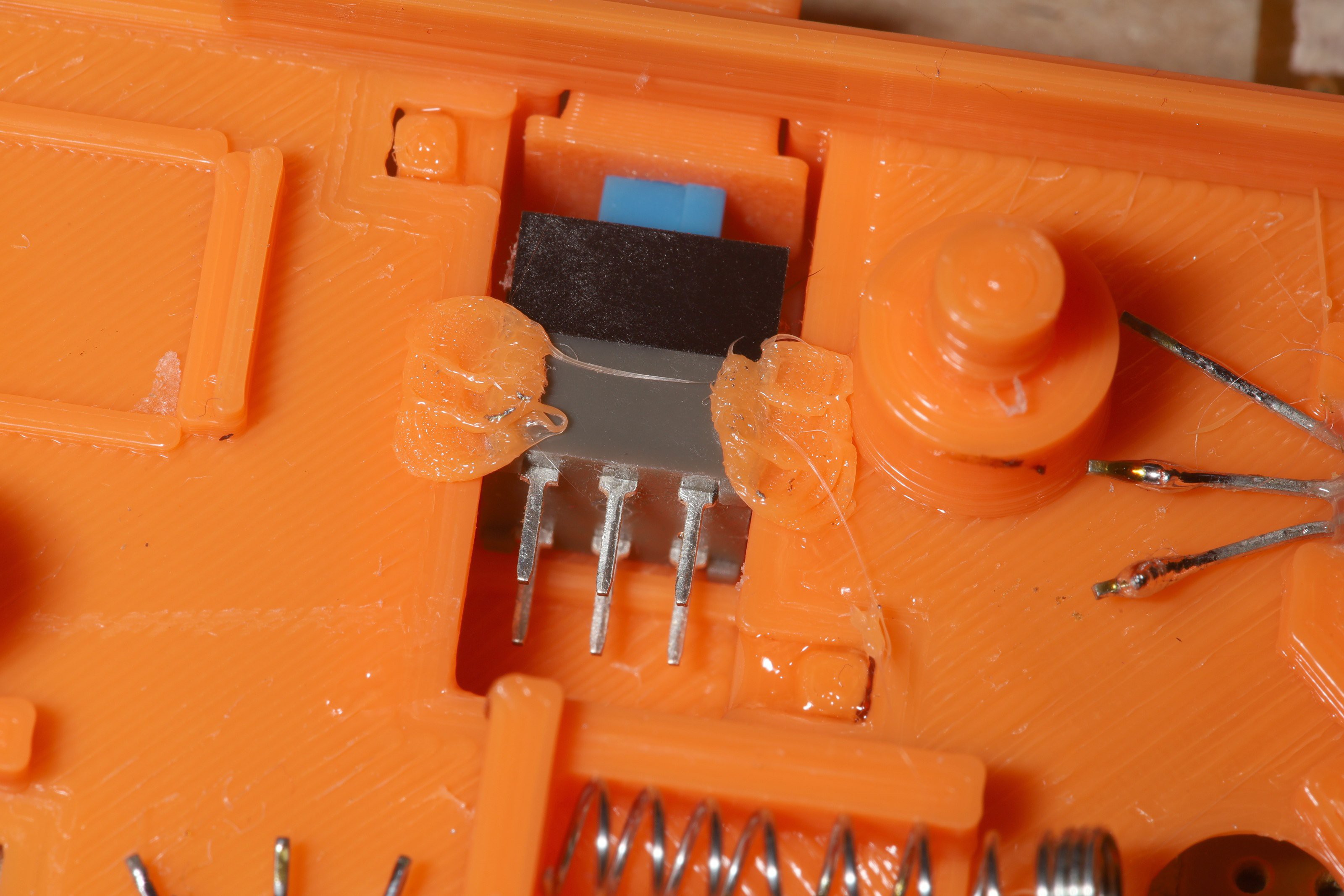

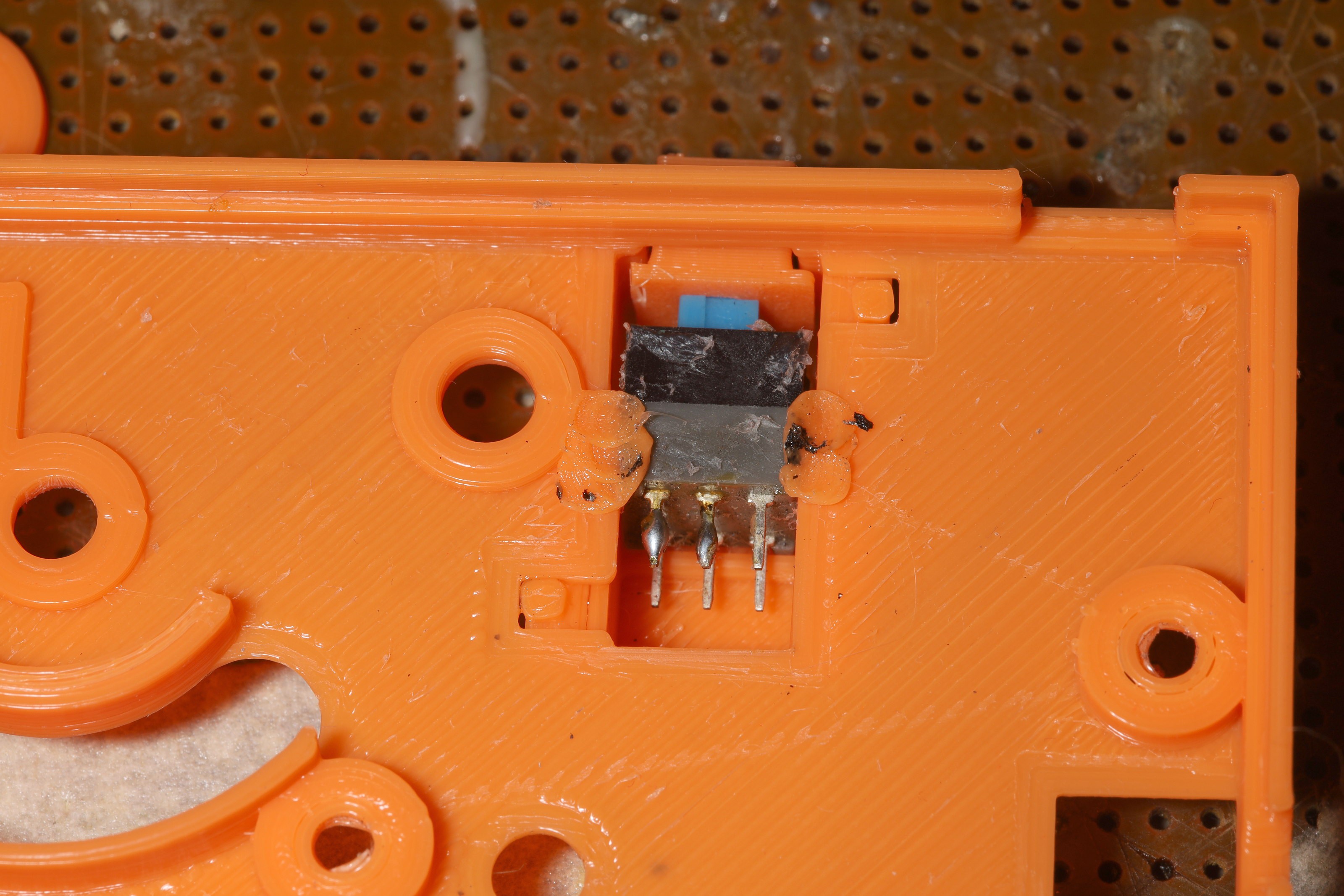

PLA welding was a successful failure. 1 switch still ended up needing hot snot. The best way to install the hall effect sensors was still to put a dab of hot snot down 1st, then press the hall effect sensor on, then flatten the dab. A dab of grease on the hall effect sensors still made a big improvement. Grease should not go anywhere else as it causes sticking. The only reason the joysticks get stuck is friction with the hot snot & grease.

A new trick with PLA welding was to melt the PLA with the iron but use the mark 1 lion paw to press it down. It adheres to the iron but not to the lion paw.

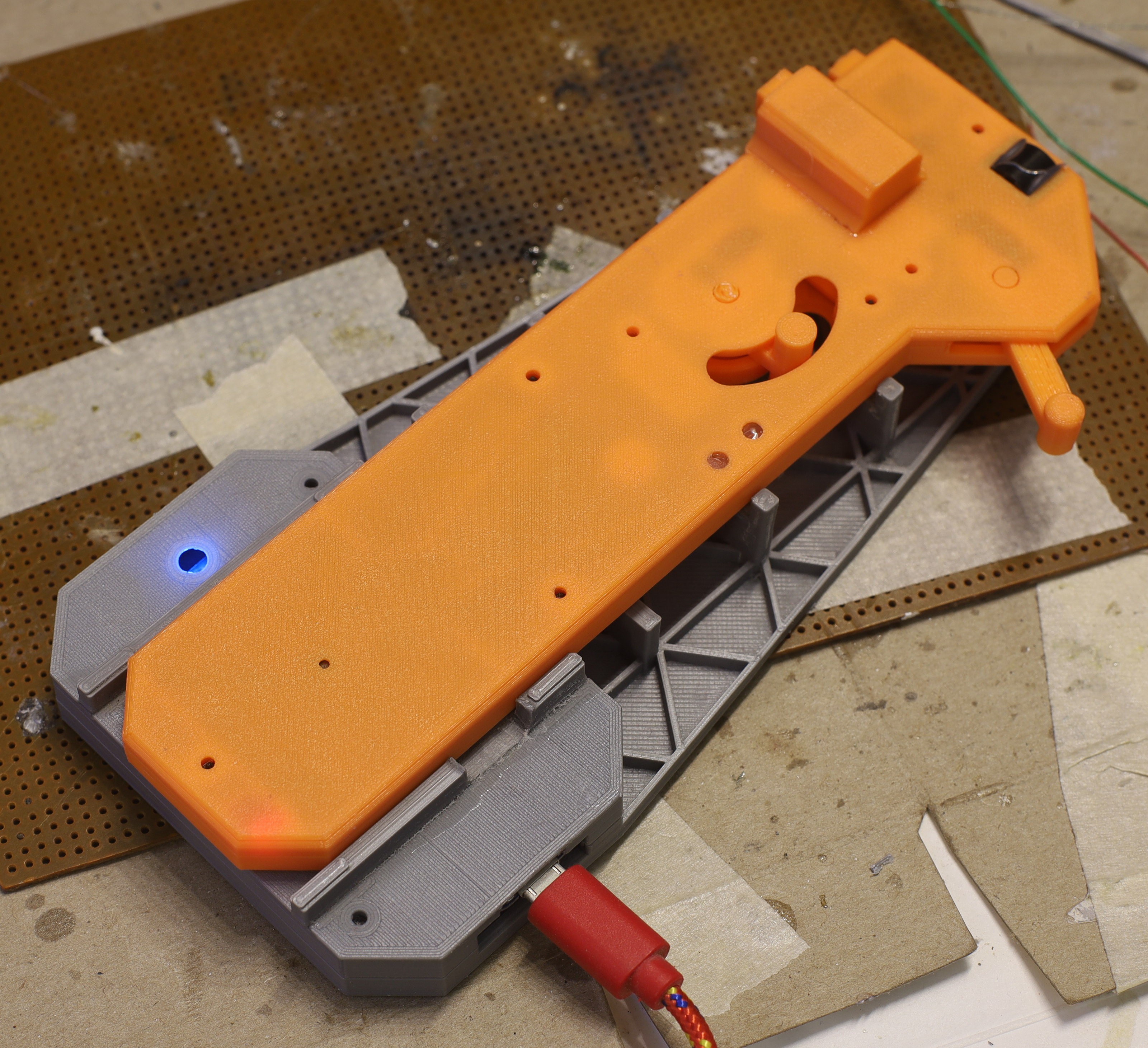

In the interest of water resistance, a sock covers the entire handle. The sock is removed for charging. If there's any evidence of how bad lions are at 3D concepts, it took a long time to realize the finger grip could be part of the sock. It actually holds water but doesn't have enough friction to stay on.

The mane problem is the welds don't go as deep as hoped. No point in using orange PLA if the sock is covering it. Low cost TPU is quite good for covers like this. Trying to stretch it over the steering stick was hopeless, so it got a cutout.

The leading idea to get it to stay on is taping the PLA to make it thicker. Other ideas are to print ridges inside the sock or make the sock narrower at a point. The problem with making the sock expand around the enclosure is welding the sock requires fitting it around the enclosure 1st. It would need a blank smaller than the enclosure just for welding.

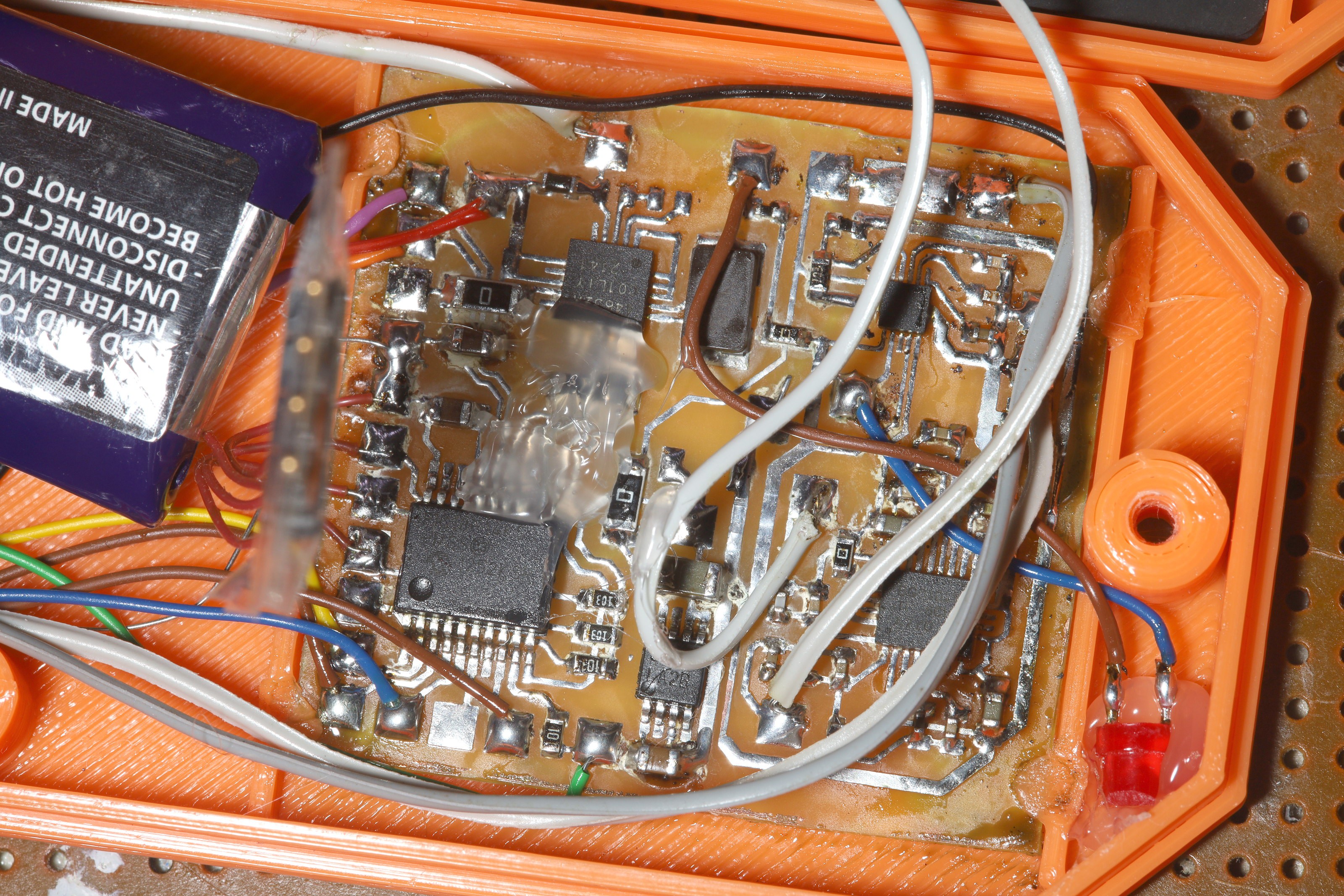

Power consumption was 50mA, so a 260mAh battery is only going to last 4 hours on a good day. It needs the 400mAh battery which somehow fit in the last one. The 260mAh required a lot of coaxing to fit in there. If the radio constantly transmits, it burns 120mA. The transmit duty cycle is 5ms on & 35ms off. The PIC has to run at full speed for the sounds.

There's 1 heroic bodge wire to connect MISO to the radio. Despite every effort, the radio failed to initialize without several power cycles. The datasheet says Vdd needs 1ms ramp time. The LP2989 has a 5ms ramp when probed.

Merely cleaning the flux got it to start despite the LP2989 issue. Getting rid of 100uF of capacitance didn't do anything.

After fighting to get the sock over the LEDs, it was decided to put the LEDs inside the case & hot snot the LED holes shut. With orange PLA, the red charging LED shows nicely but the green transmitting LED is barely visible. Transparent PLA would be ideal, but there's a real need for white PLA for an LED diffuser. Nylon paper might work as an LED diffuser, which would make transparent PLA the better deal for fabrication. LEDs that diffuse through the enclosure should be a bigger part of all designs.

The hall effect sensors are 1.3mV/G so they never saturate. There is a desire to make the handle narrower to compensate for the sock size. The steering lever should be either square or longer to compensate for the sock.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.