is a difficult problem in a $3000 apartment. The lack of space & erratic temperatures make it hard.

Rich gootubers can do whatever they want, but storing filament in the ambient air is not an option for us plebeians. It all becomes hydrated & useless.

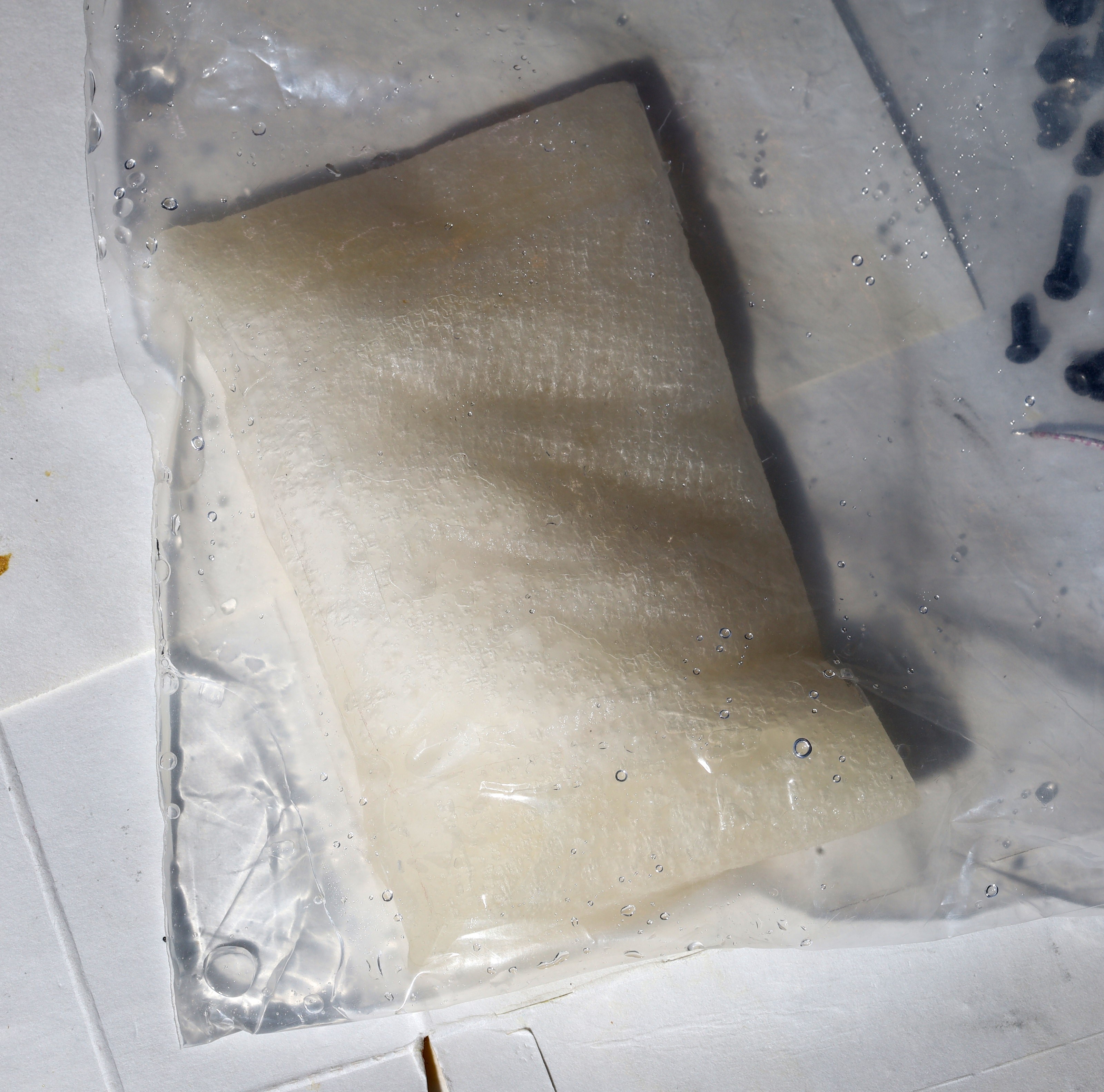

The lion kingdom started out by creating custom desiccant bags out of calcium chloride & paper towels, stuffing filament in 2 gallon ziplocs with desiccant bags. Reusable desiccants & silica beads weren't good enough. If the filament is too wet to be useful, there is a solar drier with circulating fan to heat & move air through the desiccant & filament.

The desiccant had 3 phases. When it was partially used up, the desiccant bags got hard but could still be broken up. After a year, during a summer heatwave, it suddenly liquefied & released a goo onto the filament. Definitely no use in a bowden tube. It seems when the ambient temperature gets hot enough, the filament dumps its water & kills the desiccant.

As the filament collection grew, this became unmanageable, so lions just poured desiccant in the ziploc bags. The hope is a partial saturation would get detected before it turned into goo. There's definitely a long term need for a way to store the desiccant & filament together without the 2 mixing.

The well healed have standard air tight 25"x16" containers which open from the top. The lion kingdom's $3000/month slice of inflation targeting heaven has only an 18"x18" area. Sadly, there are no air tight containers in exactly that size.

The growing filament collection makes it impractical to have a separate container for every roll or to have the rolls unstacked. The best option would be a a side loading container with shelves. There are no side loading air tight containers with shelves.

There are $120 mini fridges with most of the space taken by insulation.

There could be a shelf with multiple removable containers or ziplocs.

A better desiccant container is needed which allows it to liquefy without making a mess. It may just end up being a transparent cup & a matter of the operator keeping the container vertical. It always took some care to keep the filament & desiccant separate in the ziplocs. Accessing a roll always required taking off every roll above it, restacking them. The cup could be sealed on 1 end with a paper towel, just in case.

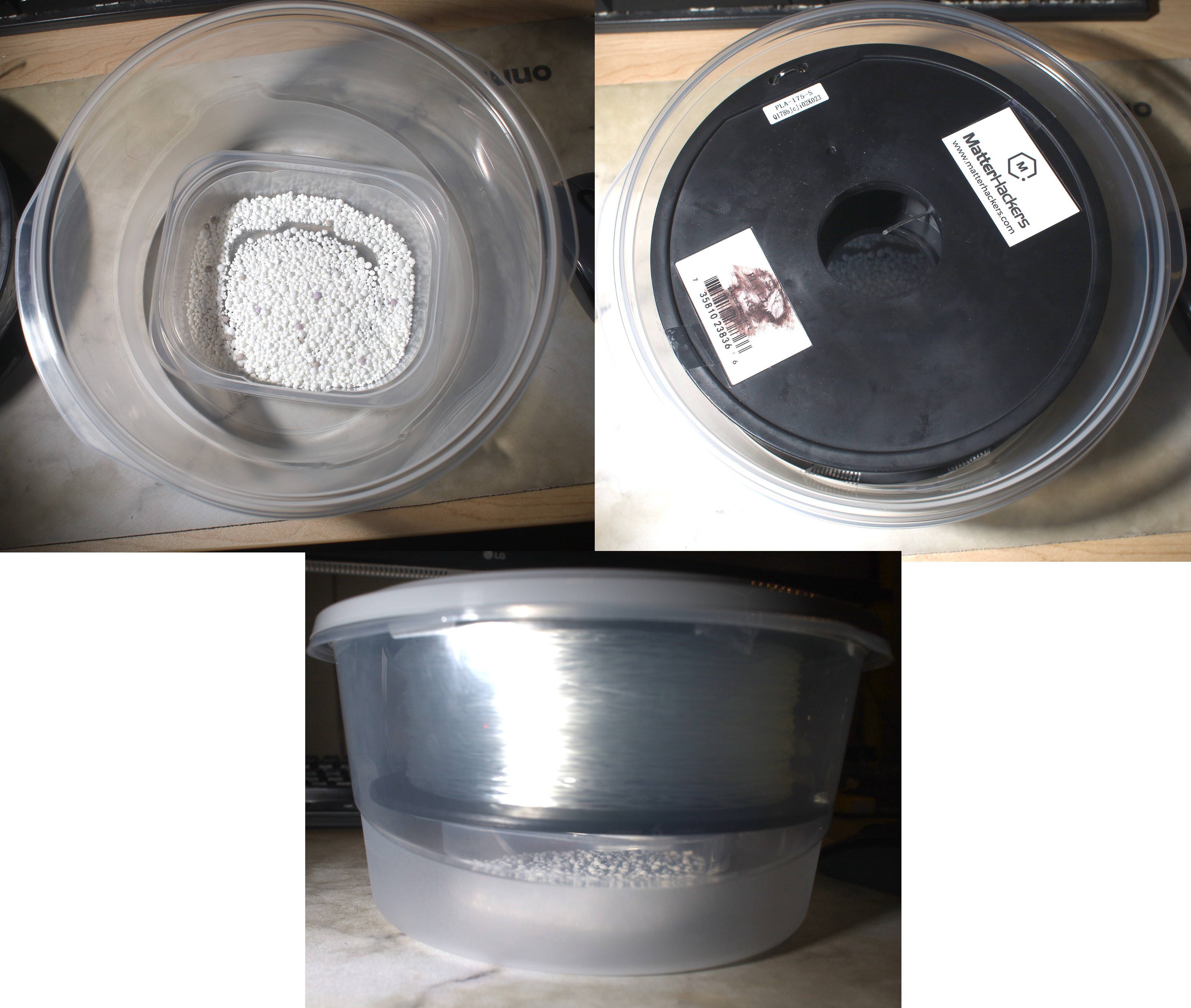

The cup could be fixed to the filament, making it a matter of keeping 1 assembly level. Big tupperware containers storing 2 rolls might be easier to keep level. The desiccant could be stored in a removable, clear container which is fixed to the tupperware.

This container seems to be the standard one for filament aficionados.

The only other container was this 2.5 gallon one. It seems to take more space.

Desiccant went into a $1 bottle. The opening had to be cut off. The paper towel is just in case it falls over.

The case could be made for pouring desiccant directly in the container & having a spacer separate the filament from it. The problem is if solar drying hardware goes in, it could rust. There's enough room to stand up the bottle when the container is sideways. The lion kingdom wants a modular solar drying package that goes into any container. The transparent bottles are just laborious to fill & might not be as effective.

There's not enough room for all 8 filament rolls in a $3000 apartment. The tupperware might be applicable to solar drying, but ziplocs with the desiccant bottles might be the only way. The best solution is turning to a custom cardboard roll, exactly sized for stock tupperware. It might be wider & narrower than standard rolls. It might be best just to keep pouring desiccant straight into ziplocs & stack filament so the desiccant hangs down 1 side of the stack.

2 gallon ziplocs are proving more abundant than feared. These are emerging as a great value. It doesn't take much dexterity to keep desiccant separate from filament in a ziploc bag. There could be a jig which attaches a filament roll to a desiccant container & this module could be stacked in ziplocs without spilling desiccant.

Savage is the only one with a somewhat decent filament facility. It's side loading. A box on the floor & a box under the printer form a contiguous dry volume. Filament goes directly from the dry volume to the printer through a tube. It has a 60W dehumidifier running constantly instead of being air tight. The trick is voting democrat so he can waste all the electricity he wants without being an environmental criminal.

He still thinks 40% is low enough, but he also doesn't make functional parts or keep filament around for long. That facility is bigger than the lion kingdom's $3000 ghetto apartment.

After a few more tries, the best solution so far was the good cook 3.7L, a lunch meat tupperware filled with enough desiccant to cover the bottom & the filament stacked on top of it. Only the top 2cm of desiccant absorbs any water. There's not enough room for the desiccant to fall over. When it liquefies, it'll stay contained. It's surprising anyone has enough room for such large tupperwares in a kitchen. They must all go to the $3 mil houses.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.