Ellie now can move properly, after working with Robotshop to debug the usage of the LSS servos.

Here she is with her ribs on--each rib has 29-32 RGB controllable LEDs. Also, you can see her janky v0 head--just a Lattepanda Alpha, Realsense D435i camera, and a battery pack zip-tied on board. The wide-angle lens hides that she's almost a meter long uncurled.

Here she is moving at last. The gait is a Central Pattern Generator, based on one used in Amphibot II: https://www.researchgate.net/publication/40755126_AmphiBot_II_An_Amphibious_Snake_Robot_that_Crawls_and_Swims_using_a_Central_Pattern_Generator . Although we don't have proper movement yet, I believe this is a function of the floor & wheel design--the wheels and tire mounts will need further iterations.

I then tried increasing the gait frequency to 25 Hz, which certainly helped with the jitteriness/audible annoying noise.

Now that the basic motion controls all seem to be working, there's lots of work to be done in finding workable gait parameters. The CPG equations/software has several parameters:

- `h`, the differential equation solver step size

- `a`, which I'm not sure how it's chosen (see the paper)

- `w`, the oscillator coupling coefficient

- `v`, the CPG frequency

- `delta_phi`, the number of sine wave periods within a body segment

- `A`, the amplitude of the gait

- `servo_update`, the update rate of positions to servos

- the servo parameters, such as gain, stiffness, speed, acceleration, etc

- the spine vertical angle, to have Ellie "press" herself into the floor to improve traction/wheel contact

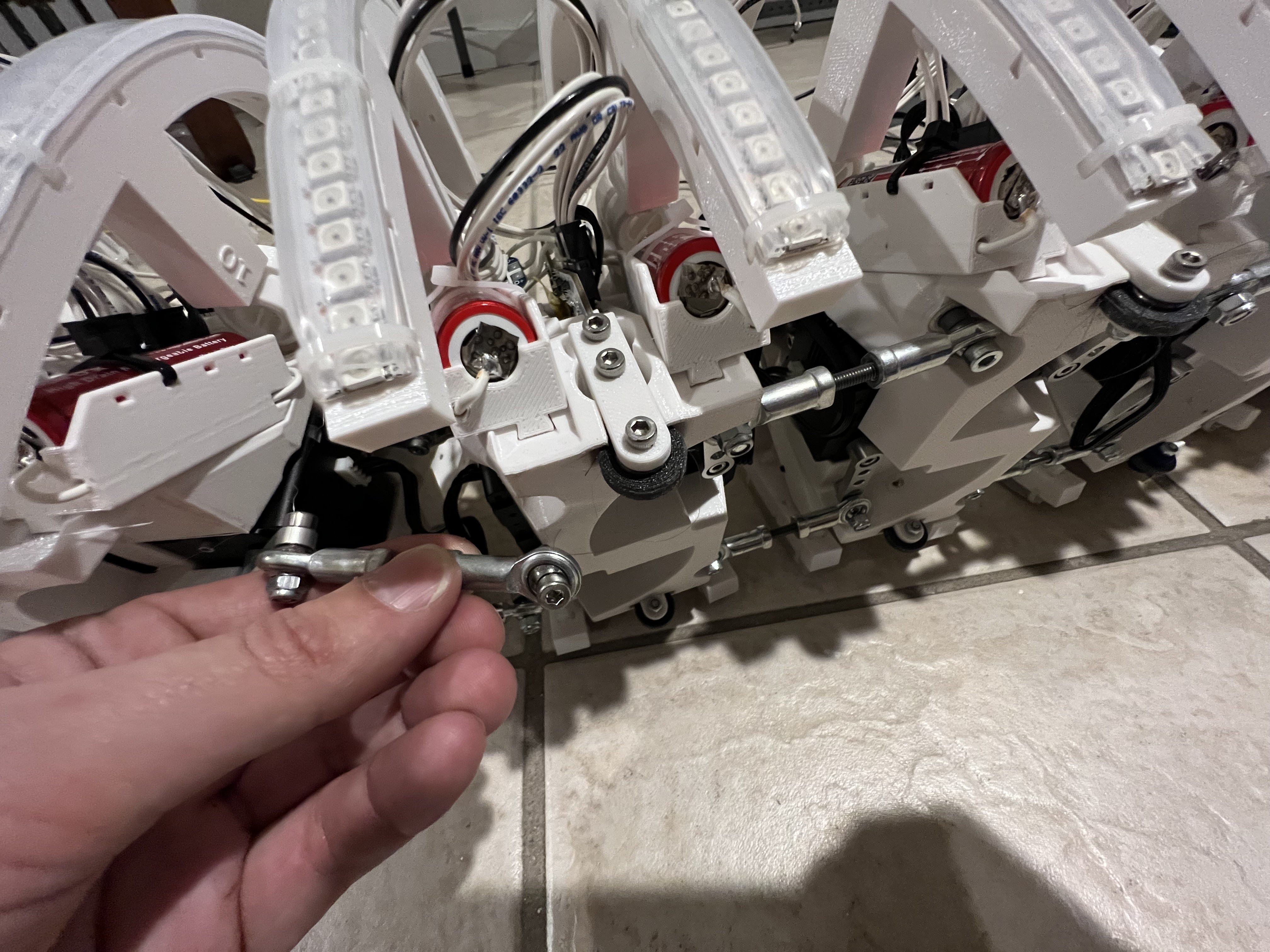

Ellie got tired after all that hard work, and one pushrod even came undone completely. Now that the movements are working, I can proceed with applying loctite to all of the pushrod connections (which I had delayed in case I needed to do major maintenance).

In the above photo, you can also see the tires, which are simple TPU parts press-fitted onto tiny 603ZZ bearings. The tires slip to the side and rub against the support struts, which is also negatively impacting Ellie's isotropic friction. Please leave a comment if you have suggestions of ways to improve the wheels!

David Greenberg

David Greenberg

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.