I know, I know. I neglected my four followers on this project for way too long ;-)

Prologue

The reason is that I decided to sell the bike instead of ... well I guess restoring it further. That has changed at least a bit when I drive her last weekend, enjoying it, and realizing that the biggest reason I never like to use her is the hassle of getting things going.

With some people, Triumph is kind of known for destroying batteries. They never really turn off like my old Honda did. When that thing was off, it could sit for months over the winter and when pulled out of the garage or even a tent in March she would fire right up! No charging or bridging required. No, not to with the 2008 Speed Triple. She kills batteries like no other bike I have ever owned or heard about. If the battery isn't absolutely full and brand new from the factory, it's gonna be dead dead in two months. In my book, that is entirely unacceptable and it needs to change.

Most people would just add a trickle charger. Okey, so I bought a 7.5 watts solar panel with charging cable for my bike. No idea how to mount it, yet, but that's probably gonna end up like a removable rear spoiler or something silly like that.

But I also want to stop the leak current altogether, so I purchased a 200A starter battery shut-off switch that I'm going to mount under the seat. So when I'm not using the bike, I'm gonna kill the main switch. It's at least very unlikely that it's gonna open by itself to burn out the alternator as well as charging circuits so it's worth risking.

The Battery

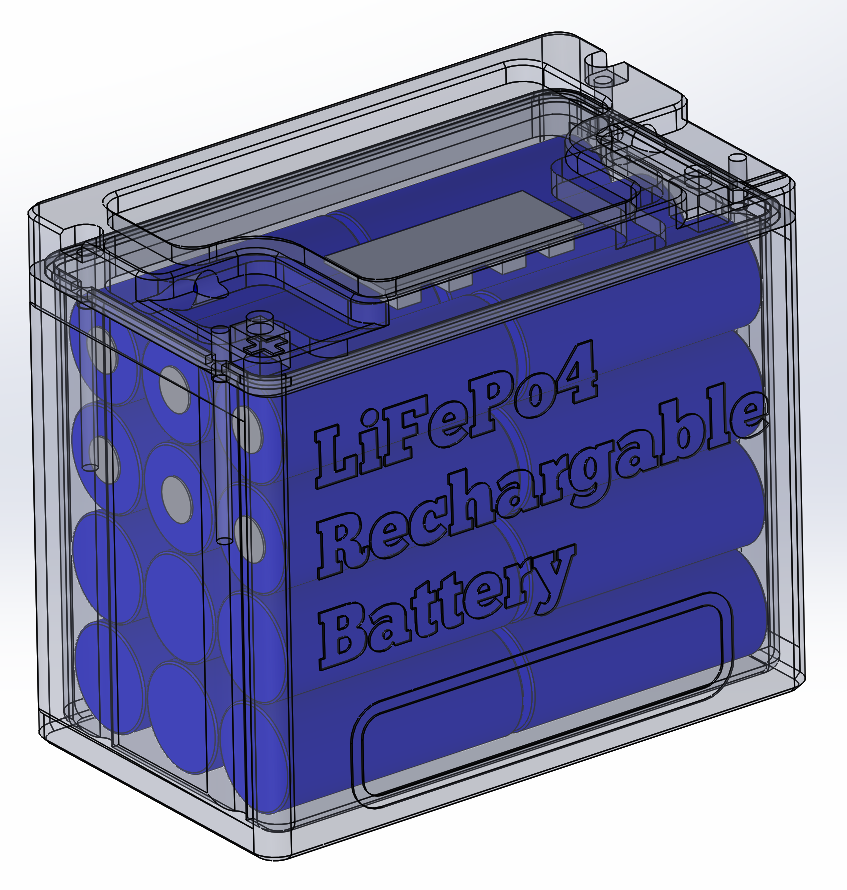

Then, I also decided to continue the actual project: Making a better motorcycle battery. As you know, I ordered parts. These have arrived a long time ago and have been patiently sitting here to be put together. The main blocker I had was the enclosure. There is not much space in the battery compartment. Especially on the long edge, it's only 150mm total. If you want the 3D printed battery case to have any strength at all, it's not a lot of space to work with considering the 26650 batteries that I going to use for this.

Then, there was the second big issue: How do I get the power from inside the pack to some type of terminal. I'm not sure I found a good solution, yet. I'm sure it's a pretty bad one since I printed the case in PLA and the terminal won't be as tightly screwed together as on a regular battery. So this is a risk I have to evaluate under test and under different temperature conditions.

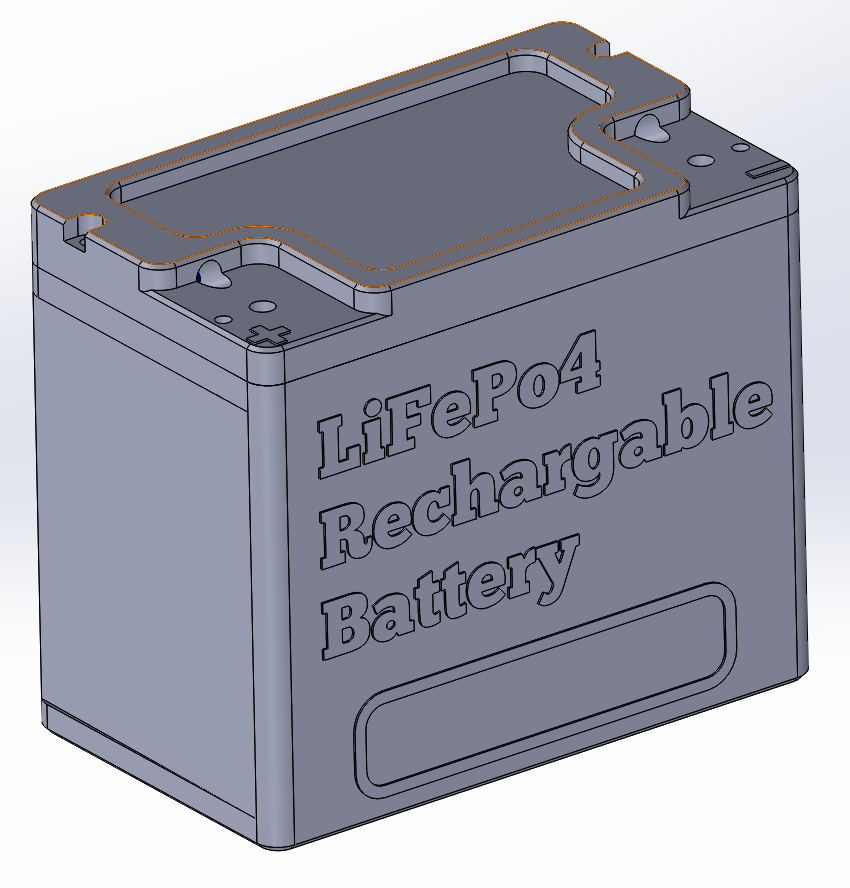

The one who spots the typo may keep it. It's ahm, artistic freedom!

I printed the entire case in matte black PLA at a 0.33 layer height to reduce print time. I am also beginning to like the esthetics again as it really has its own charm after printing lots of 0.1mm parts "because it looks like Markforge3D parts".

The pieces fit together nicely and with a little bit of flexible glue, this will be almost water tight. 3D printed parts are really not water proof, though, but the compartment is in a reasonably dry place. No high pressure washer for me!

Timo Birnschein

Timo Birnschein

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.