The occurrence of accidents in confined environments is common, many of these places can contain in their atmosphere several toxic gases and low levels of oxygen, in addition to other hazards.

The intention of this project is to create a product that constantly monitors various parameters, to detect when the worker is experiencing a malaise, or when he has some other type of accident, and then alert supervisors to trigger the rescue and thus avoid injuries that can lead to death due to lack of medical help.

For this purpose, equipment will be attached to the worker's body, which will read the blood oxygen level, heart rate and body acceleration.

The collected data is sent to the station so that it can inform supervisors of the worker's current status and issue an alert if something goes wrong.

I chose to use low cost (not necessarily bad) sensors so that the total cost is not too great. The ESP32 being relatively inexpensive, having a good balance between performance and power consumption, and already having built-in Wi-Fi and Bluetooth made it the perfect choice for this project!

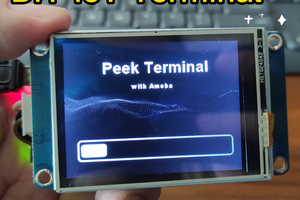

To display all information on the station, a 4.3” UART display has become the perfect choice, as it is extremely easy to program and much tougher than other displays available on the market today. Thefeatures of this display are:

- Resolution of 480x272 pixels

- 4.3" Size

- RS232 TTL/CMOS bus

- 5V power supply

- Resistive touchscreen panel (although not the best technology on the market, I was surprised by the touch panel's sensitivity and response)

- buzzer

- RTC

- 128MB flash memory

What led me to choose this display was the fact that I could find it here in Brazil through

Victor Vision, which in addition to offering excellent product documentation, has its excellent support service and after-sales service.

Travis Lin

Travis Lin

SimonXi

SimonXi

Very nice! Congratulations and thanks for sharing it