Now, after the printer got cleaned up I wanted to test if everything is still working.

Because I had no ink and make up fluid, yet I wanted to test out everything with destilled water.

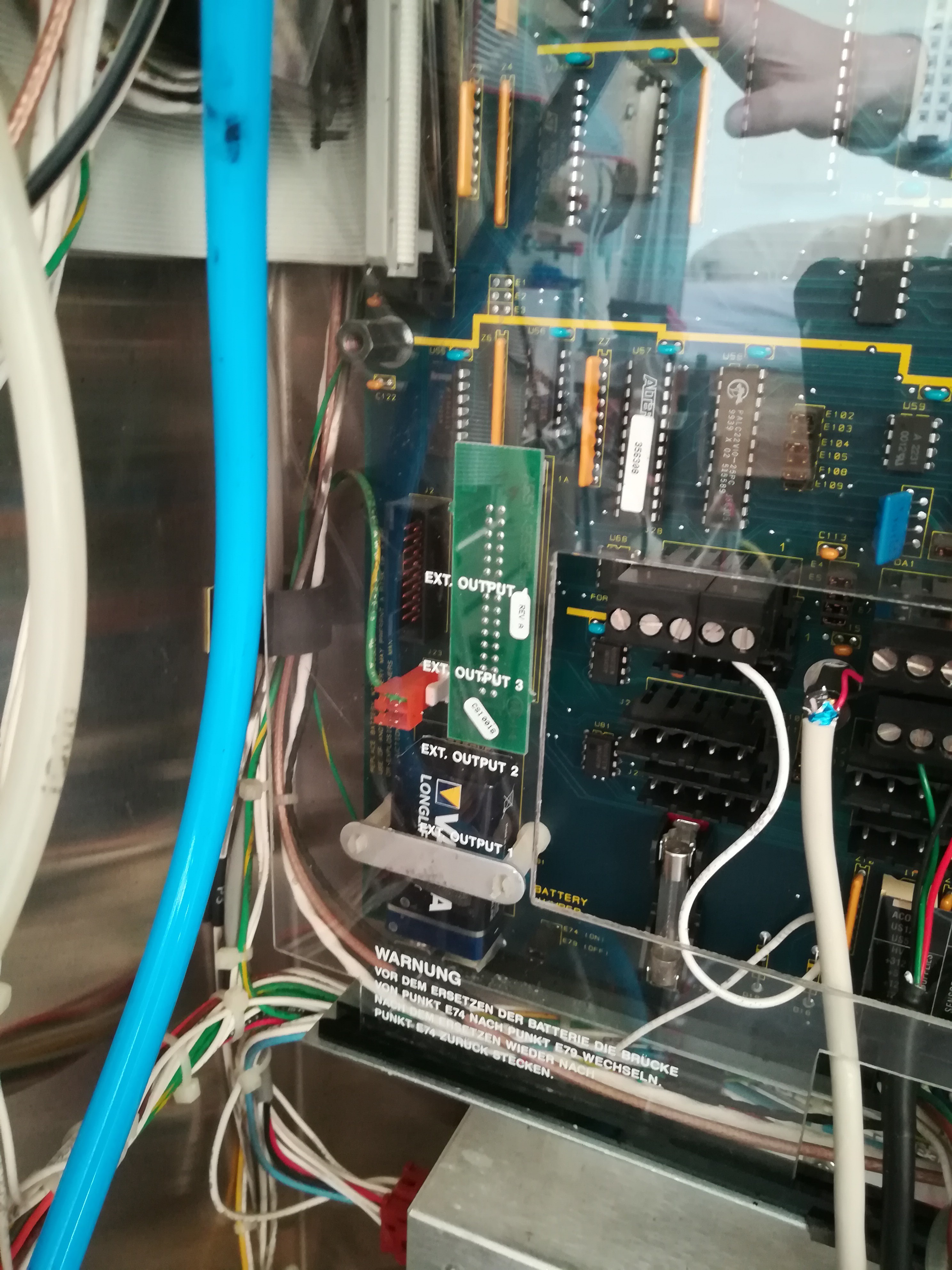

The first thing I did was replacing the internal 9V battery that is used to keep the stored data in the memory, power a real time clock and also for the startup of the printer (I guess to meet some industrial safety standards or so).

After that I connected a compressor, set the pressure regulator to 5.5bar, connected a power cord to the printer and tried to start up the printer.

Moments after startup there was the noisy sound of vented air to hear, seconds later the compressor's pressure dropped below 6bar, so that it turned on and minutes later the printer shut down because the pressure dropped below 4 bar at which the printer detects that there is too less air pressure to work.

So here is what happened:

Besides pressurized air the printer also needs vacuum to operate, what is by default created by a pressurized air driven vacuum generator.

This thing had a really high air consumption and was also really noisy, so I had to find a better way to supply vacuum.

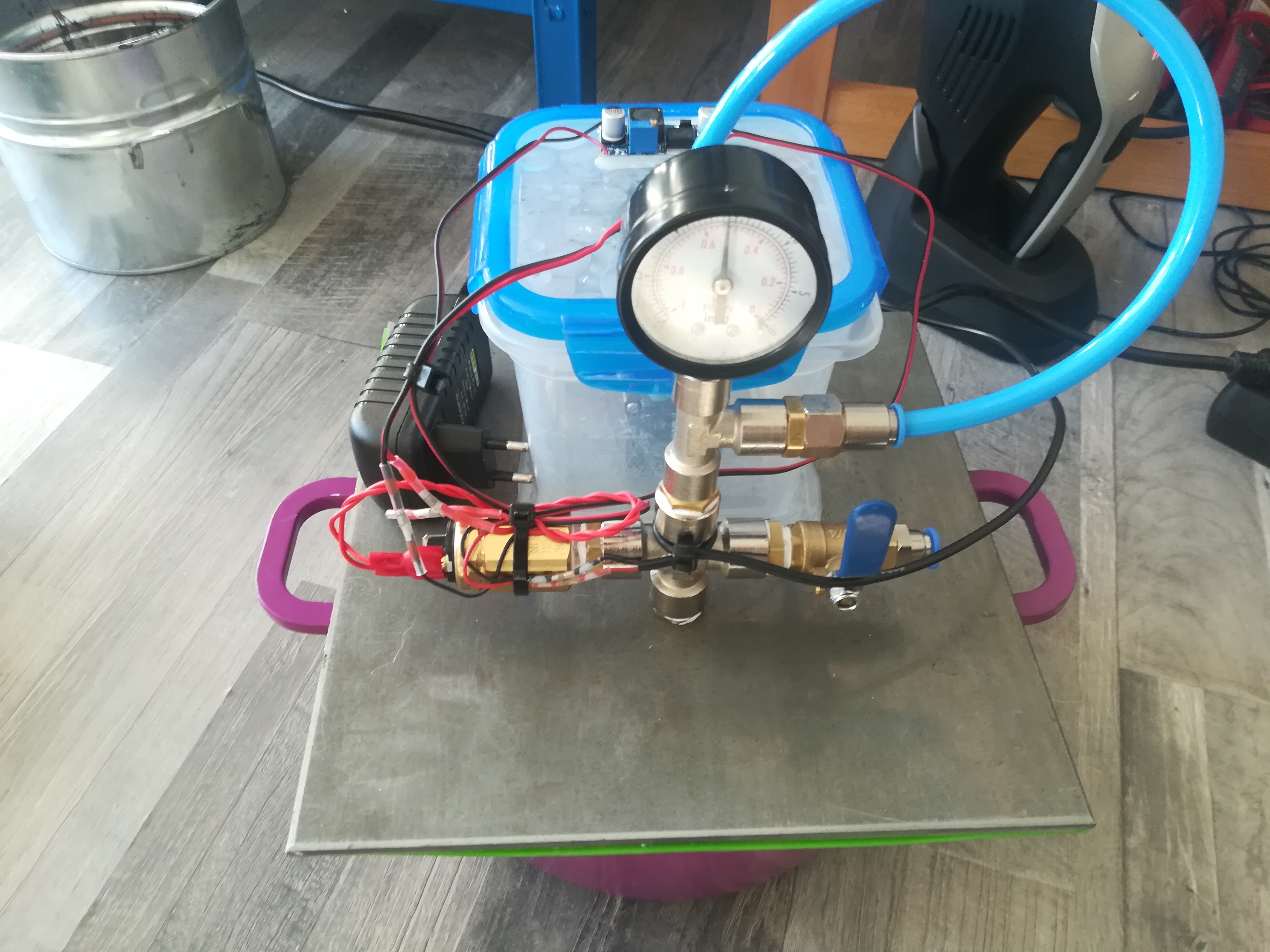

By default the printer only had a pressurized air connection and now I added an additional connection for a vacuumpump.

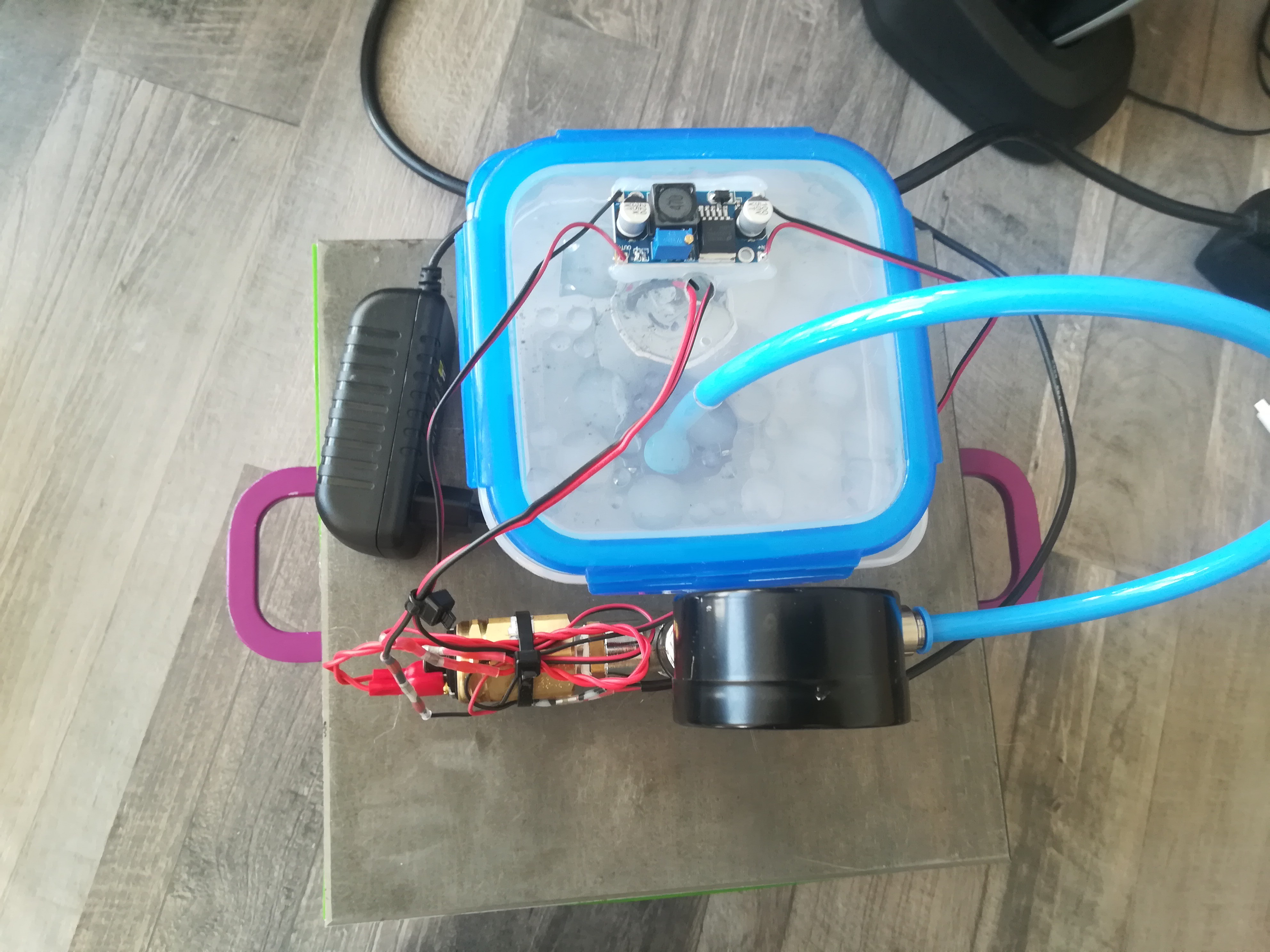

For the first test I used this vacuum pump setup with vacuum tank, but later I changed to another setup because I had the concern that aceton vapor which builds up in the tank could cause an explosion or fire.

So after adding a vacuum pump to the air compressor I turned both devices on and started the printer.

After fixing a problem with the rubber check valves which got stuck together by the last used ink, that took me some time to find the printer worked and the destilled water could circulate in the ink circle.

After making sure that everything works I drained the destilled water and shut down the printer.

A few days later the ink and make up arrived and I loaded the printer with it.

After loading I checked that the viscosity got measured correctly and that there no errors occur by letting the printer run for a few hours.

After that I selected the right nozzle drive parameters to split the ink stream into dropplets and turned on the high voltage.

No error has shown up, what shows that the loading process should have been successful.

To bring the functionality testing to an end I performed some test prints and everything seemed to work.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.