New Printhead

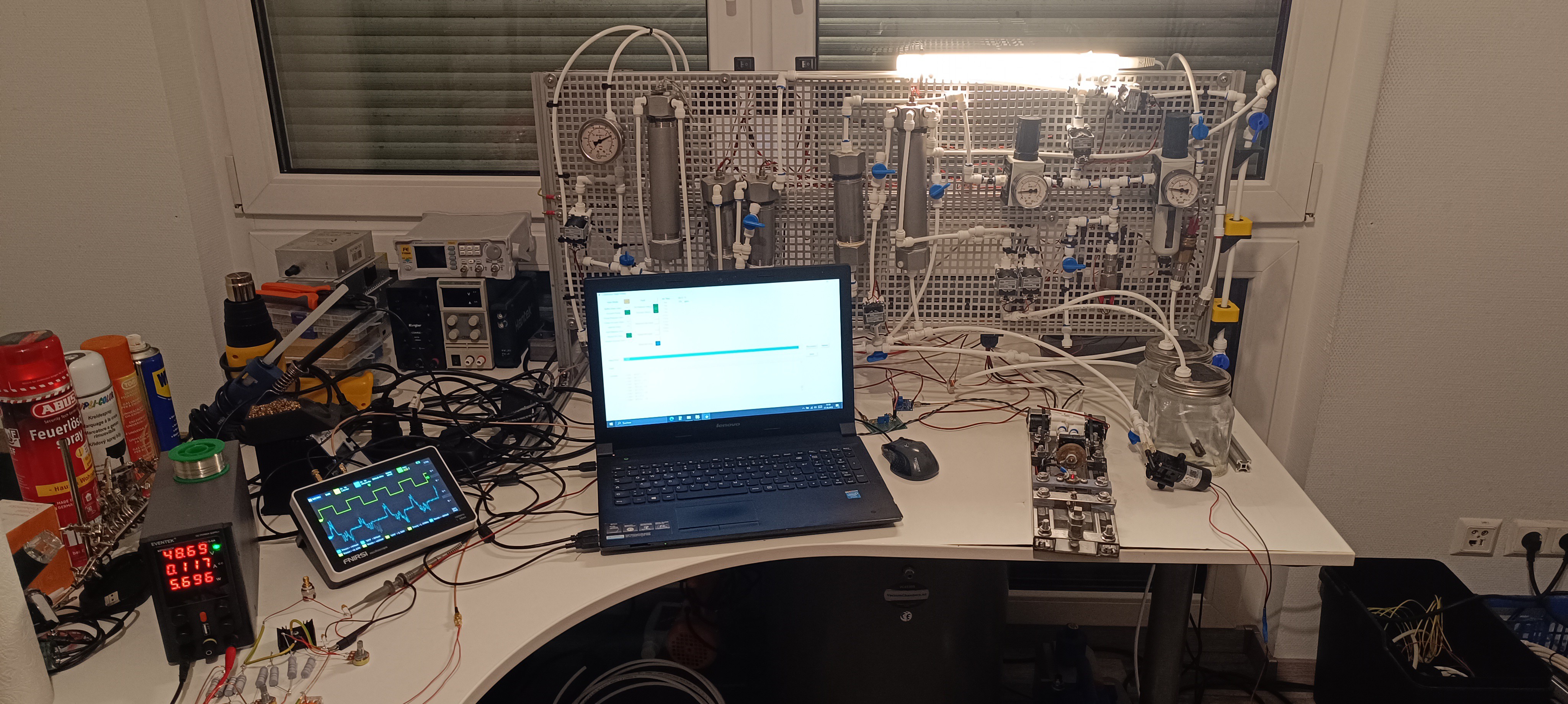

Over the last few days, I worked on a new printhead that is more resistant to corrosion than the last one.

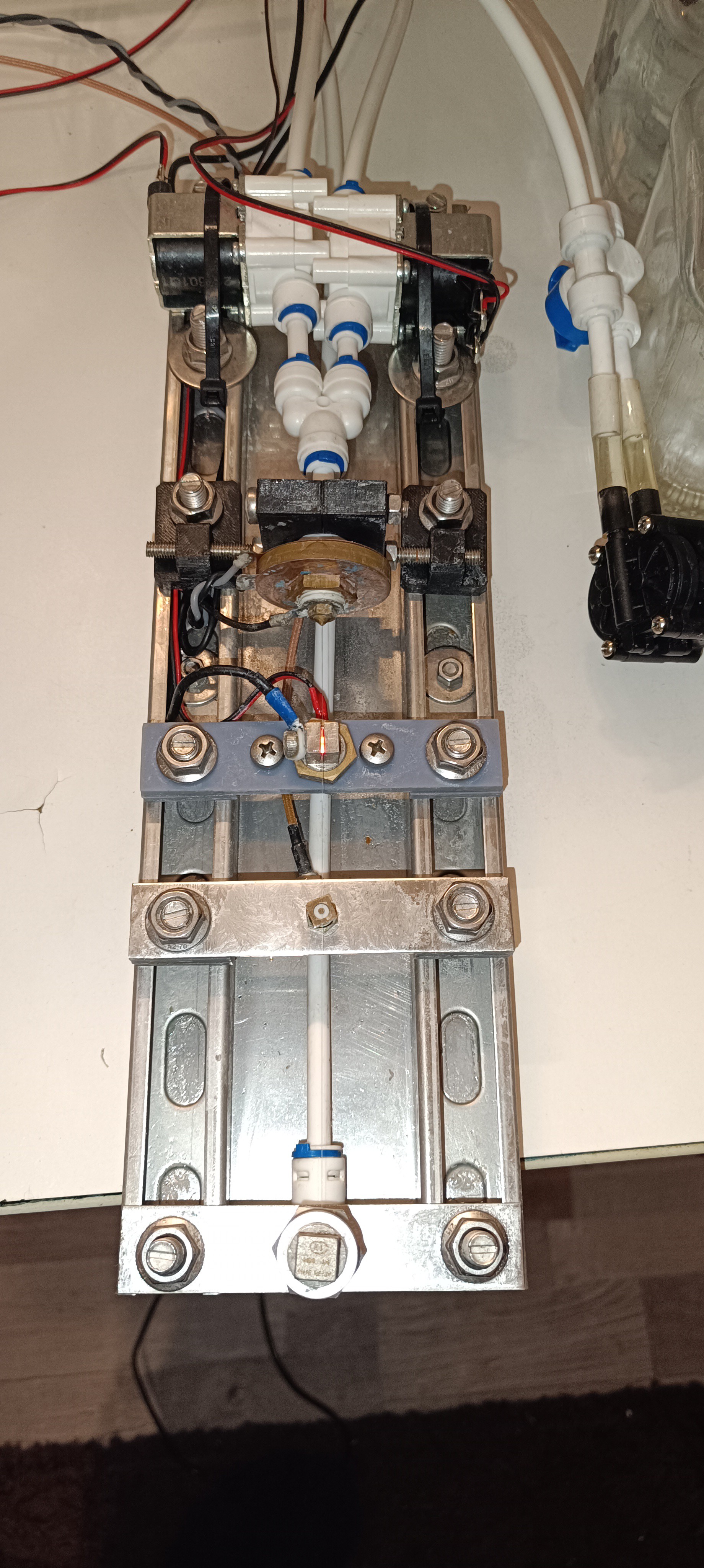

Here, you can see the latest prototype which is specially designed for charge testing and has therefore no high voltage electrode and a too-wide gutter which will be replaced when the charging works reliably:

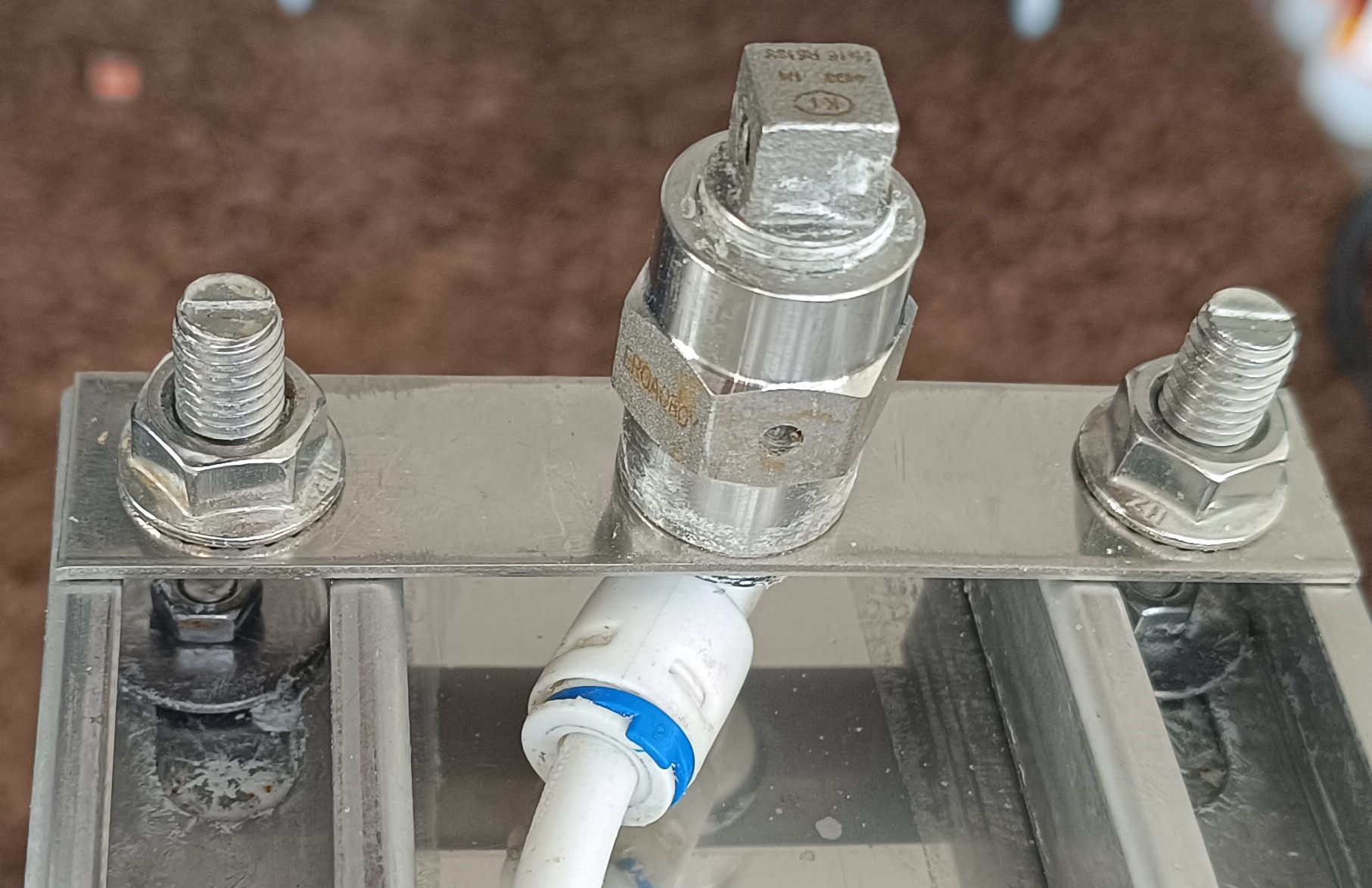

In addition to the stainless steel bottom, which I just took from the last printhead prototype, I also replaced the 2040 profiles with 26*18mm stainless steel mounting rails so that the printhead body (including screws and nuts) is now completely made out of stainless steel.

Starting from the back:

- The brass valves were replaced by the same valves as on the printer grid.

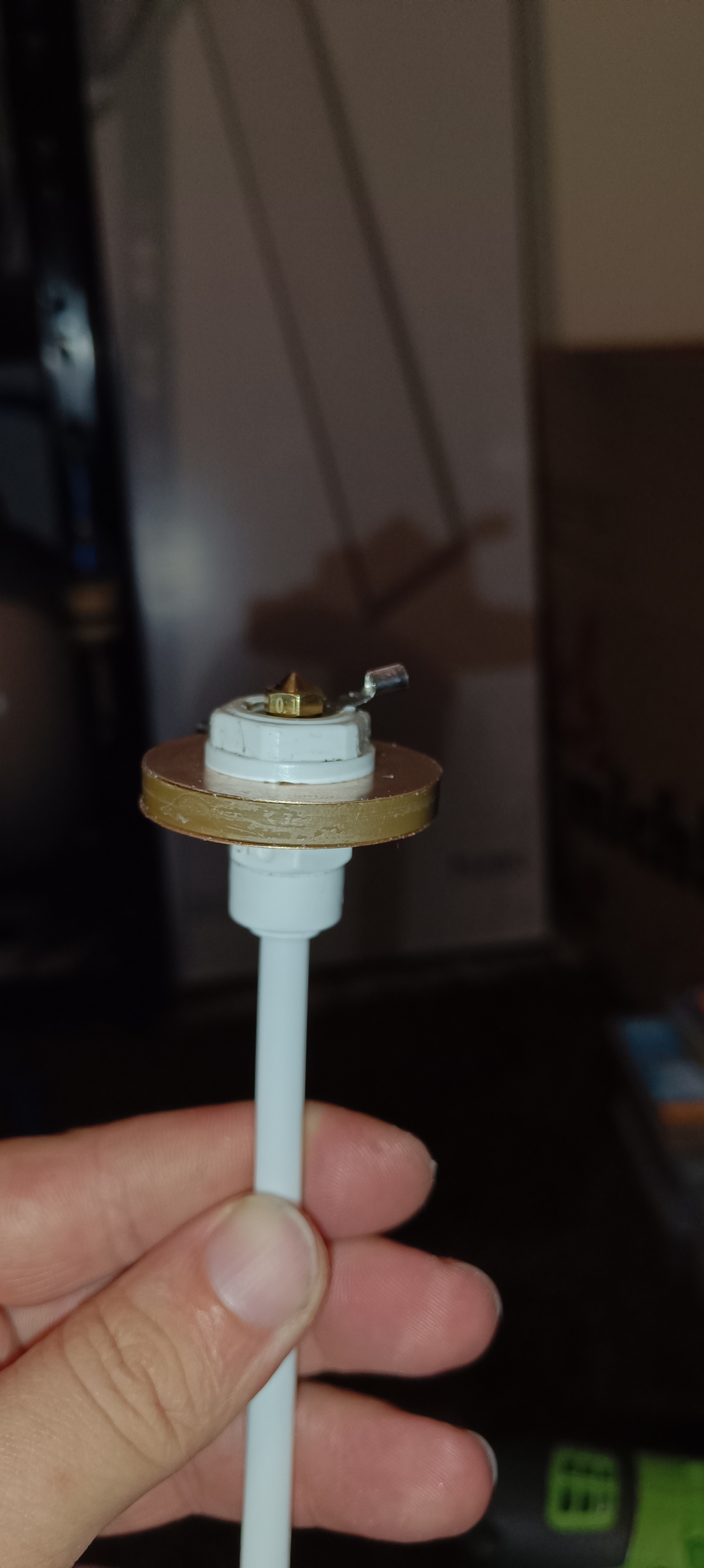

- The nozzle assembly is now made out of a plastic 1/4 inch fitting which can in contrast to a metal one come in contact with the "hot/powered" elements of the nozzle assembly, so no isolators are needed.

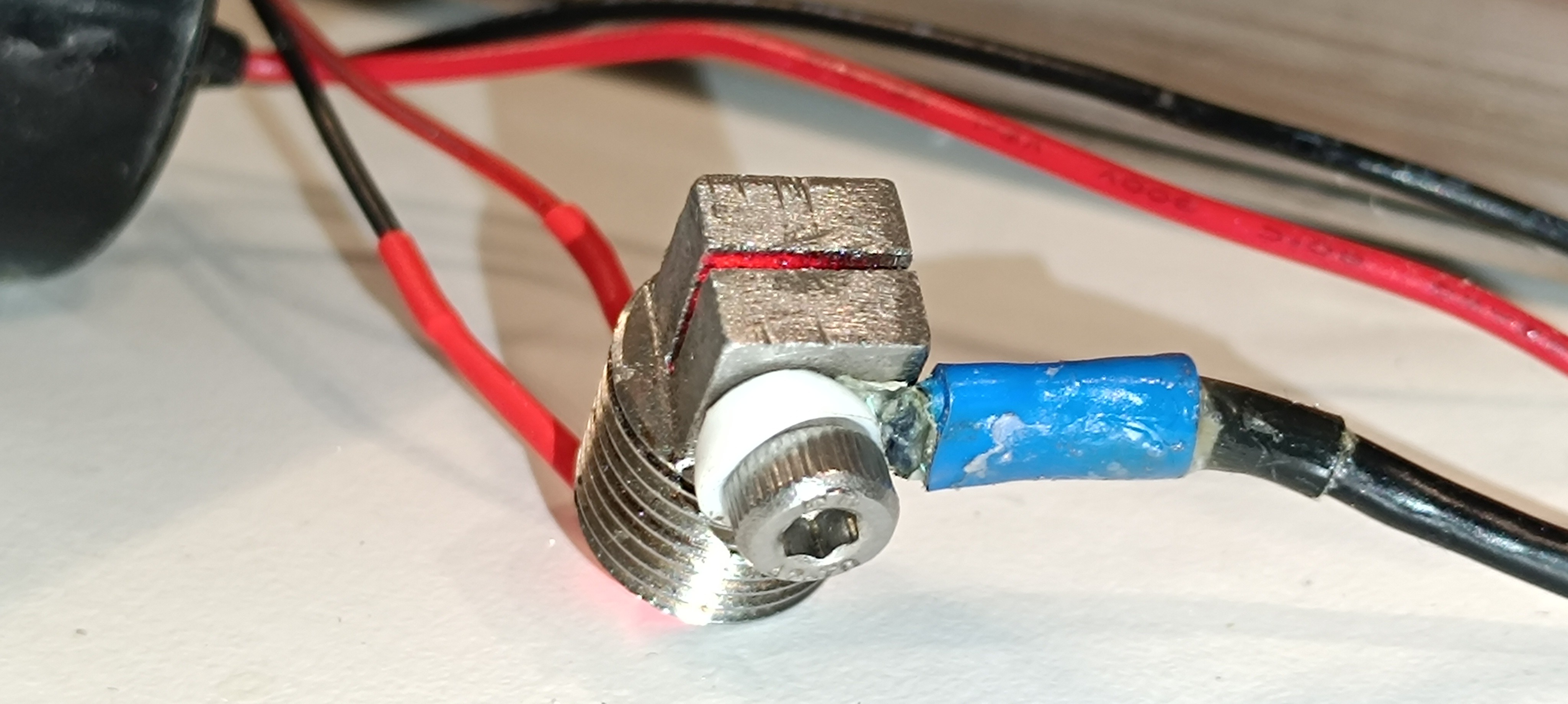

- The charge electrode is now made out of a stainless steel 1/4 inch fitting with a slit cut in it and a hole at the bottom for the strobe LED that illuminates the ink stream to make the breakup visible.

- The phase detector antenna/feedback sensor is now mounted onto a stainless steel bracket.

- The high voltage electrode is currently missing.

- The Gutter is now made out of a 1/4-inch stainless steel fitting and a plastic elbow fitting mounted on a stainless steel bracket.

In addition to that I'm currently trying out Sodium Acetate as a "conductivity-increasing agent" which seems to be a lot less corrosive than the salts I tried before.

With the new upgrades the printhead should no longer have the corrosion problems from before and is now ready for a new series of testing.

Here is an image of the whole setup:

The next update will be about the new viscosimeter which I'm currently working on.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Dear Dominik, sorry I hasn't saw one fatal error when you sent me pictures last month. Resonator Probe can't has any contact with Ink, remember Ink is conductive and you are losing Resonator signal to the ink and getting 'spurious' from Charge Electrode as remaning charging flow is dissipated to Nozzle ground. I can calculate one Drops Generator for you if you want , but we will need machine it.

Are you sure? yes | no

Hi,

in the current design the piezo ring has no electrical contact to the nozzle or ink. It's mounted on a plastic fitting that isolates it from the conductive ink.

Are you sure? yes | no