The long awaited pump failure took only 9 months. Instead of a sudden pouring of water all over the floor, it manifested itself as the motor spinning without moving any water.

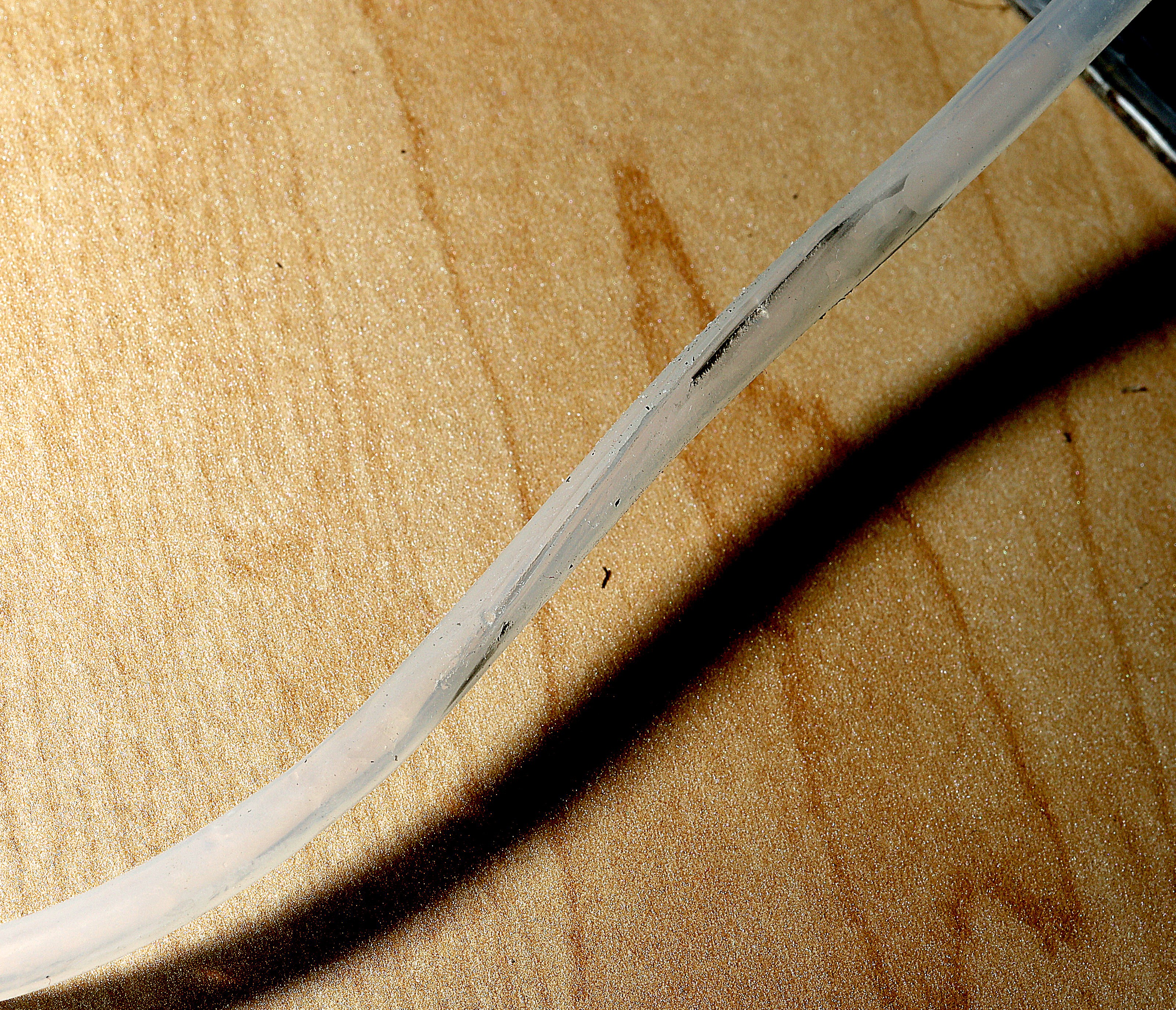

The 1st problem noted was the silicone tube being split down the middle & slowly dripping.

The stock motor has a segment of tube between 2 barrel connectors. To conserve material, don't cut off a segment of good tube to replace the entire segment between the barrel connectors. Just throw out the bad section & 1 barrel connector. Slide just enough good tube into where the former barrel connector was, every time it wears out.

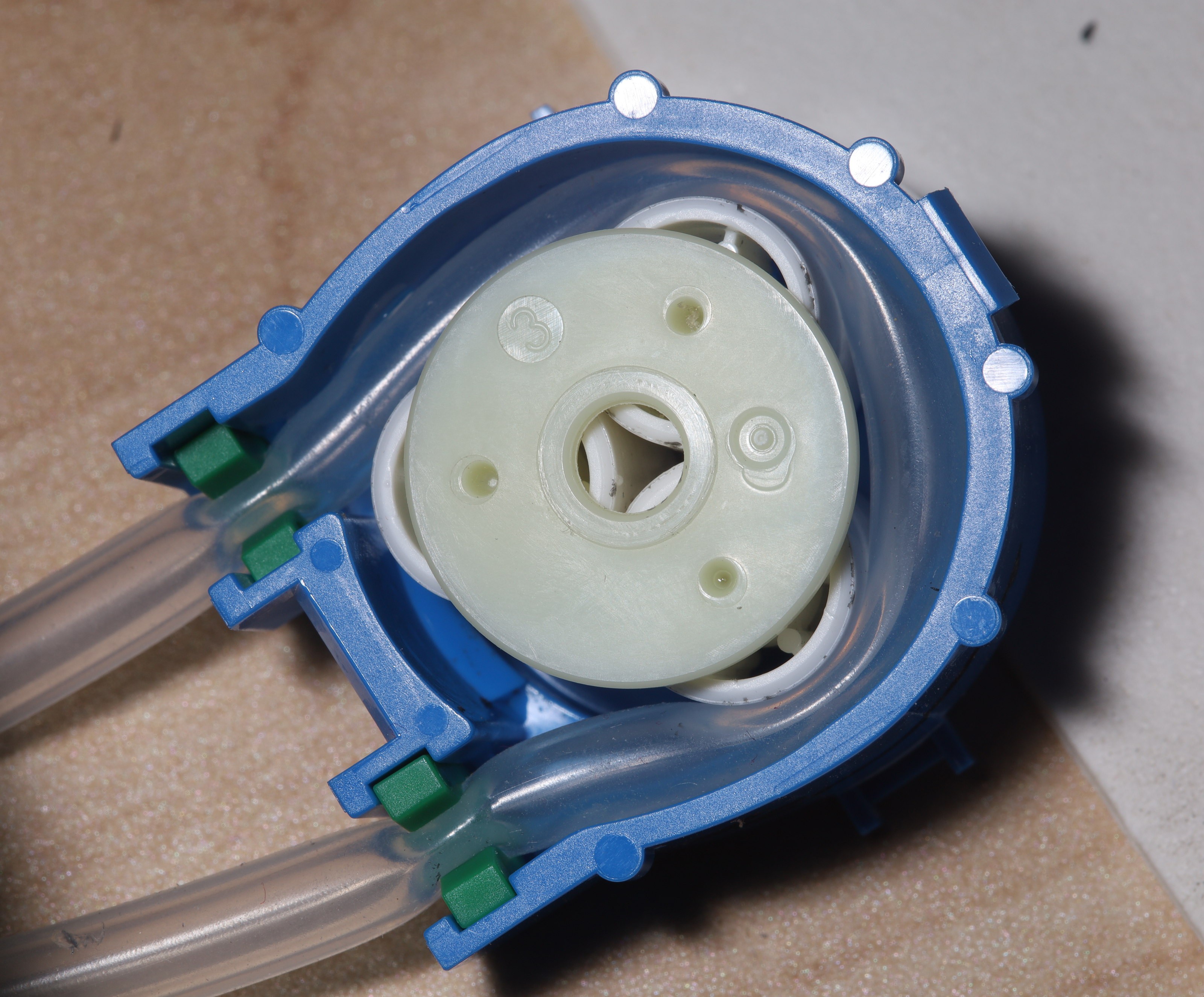

Once new tube was inserted, the motor still didn't have any luck spinning the rollers. Either the tube needed some fidgeting to get it loose enough or the rollers are truly worn out. It eventually started working again.

Most likely, when the tube split it no longer pressed the rollers against the motor shaft enough to get good friction.

Important to note the direction of pumping when inserting the new tube.

The transducer replacement, pump repairs, water level sensor erosion, & tank leaks have made this quite a manetenance nightmare. Every gadget involving water has lived up to its reputation as a manetenance nightmare. There's still a desire to have it automatically manetain 40% humidity, but investing more time in such a manetenance intensive gadget isn't appealing.

Maybe a lion could make a more reliable pump out of a servo & imperial unit tubing. The tubing is going to wear out fast, no matter what. There are still anecdotes of common 3V brushed motors being waterproof.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.