Designing ESD protection for measurement circuits is often difficult. Parasitic capacitance and leakage currents must be minimized so that the signals are not distorted.

As a complete unit, the differential probe is already quite well protected: the 9 megaohm resistors in the input divider will limit ESD pulses to very low currents, low enough that the integrated protection diodes in OPA659 can absorb them. To add extra protection for when cables are being attached, ESD diodes can be added to the inputs. PESD5V0X1BT is probably a good option, as it has relatively low clamping voltage but also low leakage current and capacitance. PESD4V0Y1BSF would be even better, but its 0201 package is getting too small for me to reliably assemble.

That takes care of the amplifier protection.

But do the cables themselves need protection? After all there is a small ceramic capacitor and SMD resistor in each accessory, which could get damaged by a current pulse. Finding a suitable ESD diode for this proved difficult, as most 60 volt ESD diodes have both large capacitance and large leakage currents.

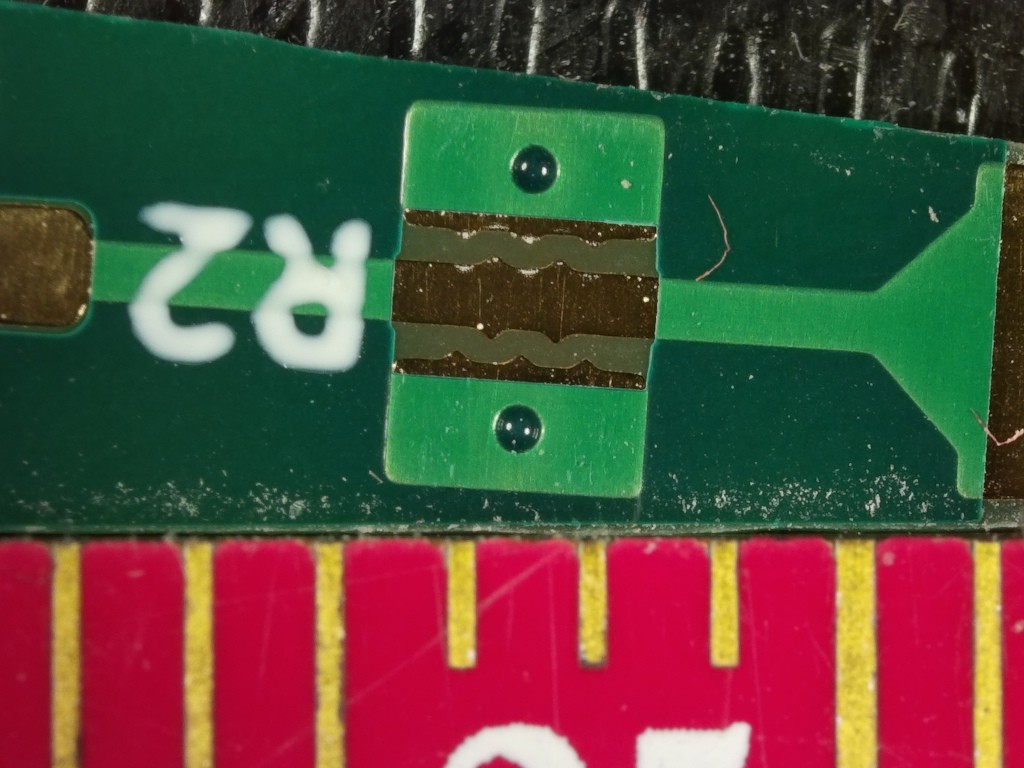

One alternative is to use a PCB spark gap as rudimentary protection. I got some boards made, and a 0.2 mm gap arcs over at 800 volts. I still need to finish my ESD tester to find out if there remains risk of damage to the probe assemblies.

Petteri Aimonen

Petteri Aimonen

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.