Most of the low cost passive smart bms that are on the market, in my opinion they all have one limit in common: low balancing currents, from 30mA to 100mA

Anyone who has experience with lithium cells, especially with Lifepo4, knows that with use, the cells can reach differences that are really difficult to compensate with such low balancing currents...it takes many hours of balancing!

For this reason, I have chosen to make a BMS capable of balancing at 1 A.

The challenge was clearly to achieve this goal while maintaining prices, dimensions and temperatures at acceptable levels.

I chose the experimental method.

I defined the volume of the module that I would dedicate to the resistance:

(W20mm x H40mm x W10mm)

After that I compared three types of power resistor, each soldering them on their own prototype board:

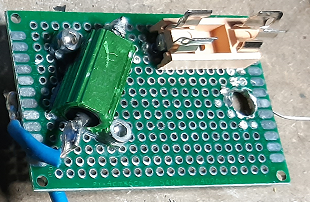

1 – n.1 armored resistor 3 ohm 10W

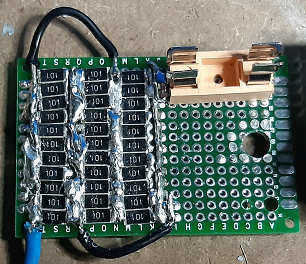

2 – Parallel of n.33 smd resistors 100 ohm 1W: equivalent to 3 ohm

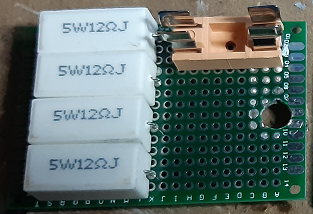

3 – parallel of n.4 cement resistors 12 ohm 5W: equivalent to 3 ohm

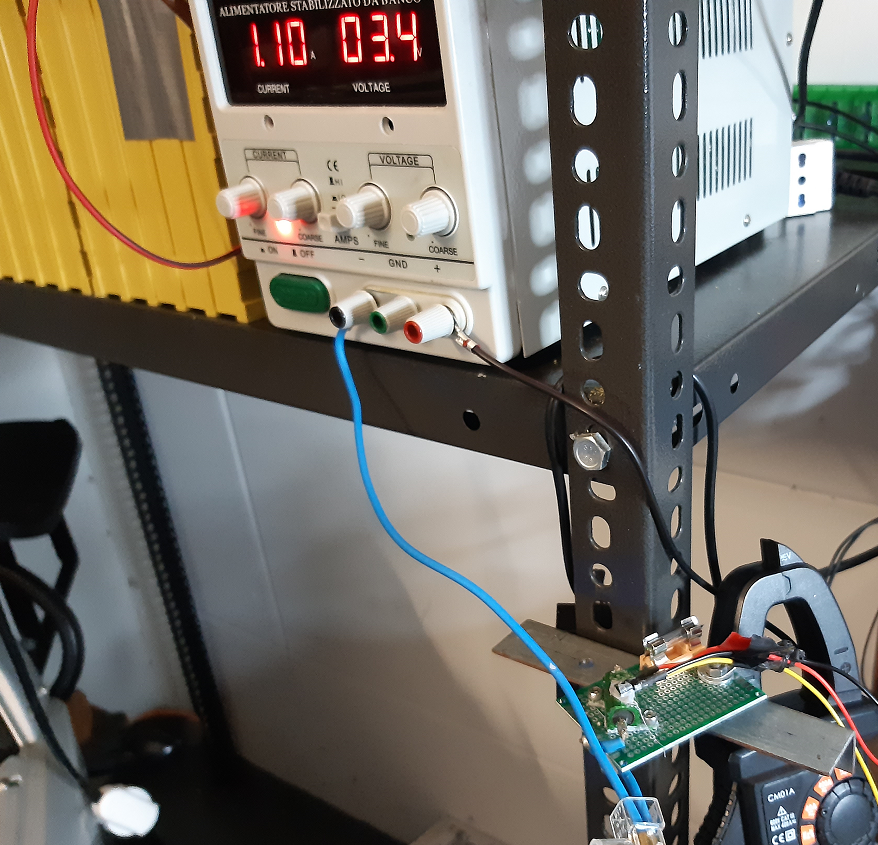

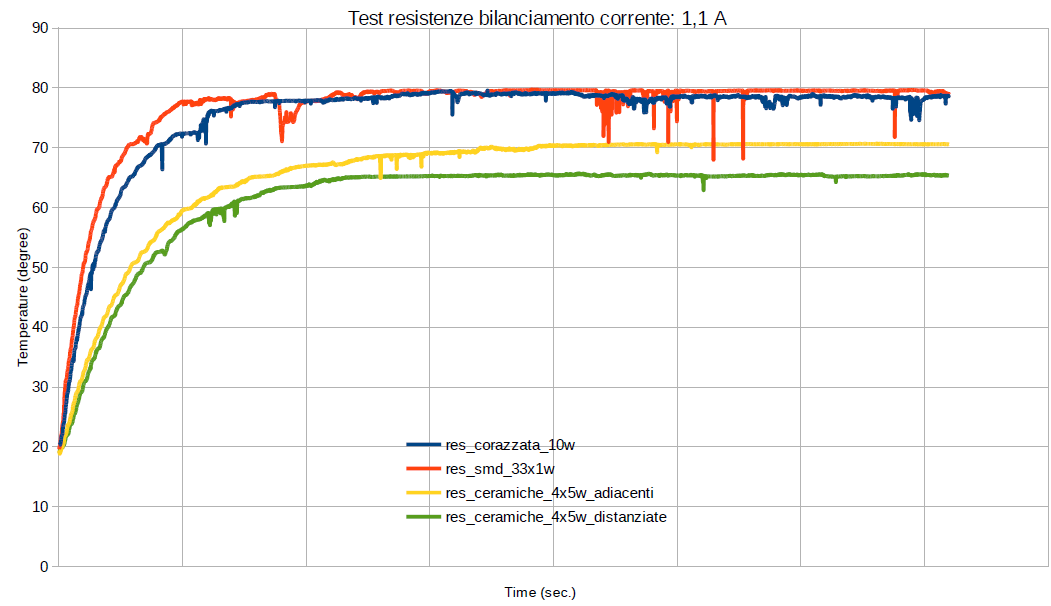

Then, under the same environmental conditions (same day, with ambient temperature: 17 °C), I applied a voltage to each of the prototypes, in order to have the same balancing current (1,1 A), for 1 hour.

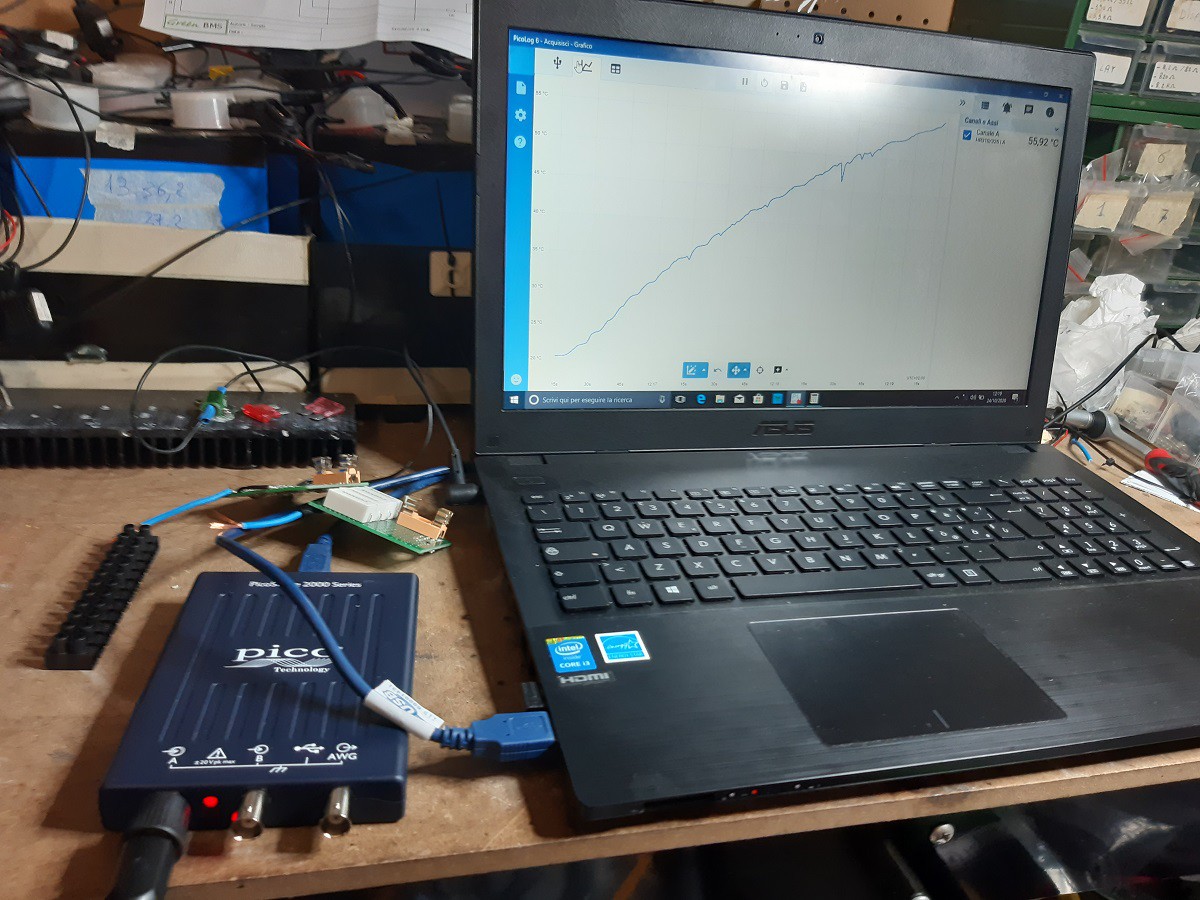

During the balancing I measured the temperature on the body of each resistor using the TMP36 chip, acquired by my Picoscope 2204A oscilloscope and I recorded its trend using the PicoLog application.

For the cement resistors I did a double test: the first test with the resistors in contact, the second test with the resistors slightly spaced from each other, in order to allow the passage of air.

This is the result:

The test shows that:

1) cement resistors heat up much more slowly and reach a temperature of about 10-15 ° lower than other types

2) spaced resistors are better than resistors in contact

3) smd and armored resistors have more or less the same behavior

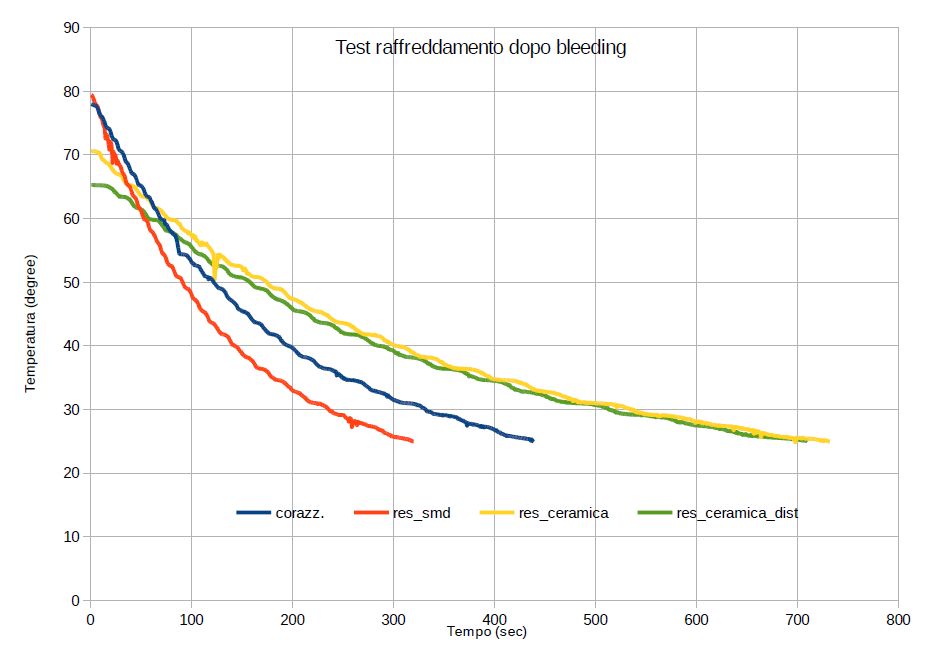

The following graphic shows temperature trend after disconnecting the power supply (return to ambient temperature).

From this measurement, it can be seen that on the other hand, smd and armored resistors have faster cooling time (5-6 minutes), while cement resistors take longer time (11 minutes).

After these tests, also considering the prices, I decided without any doubt to use the cement resistors on Green BMS cell modules.

Sergio Ghirardelli

Sergio Ghirardelli

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.