Given the aim of developing a rotor module capable of applying its full thrust in any direction, the more obvious solution is to place the rotors on a structure that rotates according to two perpendicular joints. Such a mechanism is called a gimbal, and it is largely employed in camera systems. The immediate limitation that arises from such an approach, however, is the wiring. Every active rotor tilting mechanism is limited to turn by how much its wire connections can wind around the rotating axis. The standard solution for these wiring constraints is solved by employing slip-rings, which are essentially rotary electric connections. Once again, this is common on gimbal camera stabilization systems. However, brushless electric motors used for propulsion systems tend to draw large amounts of electric current, leading to large and heavy slip-rings. This extra weight is undesirable and would limit the flight time and payload capacity of the vehicle considerably.

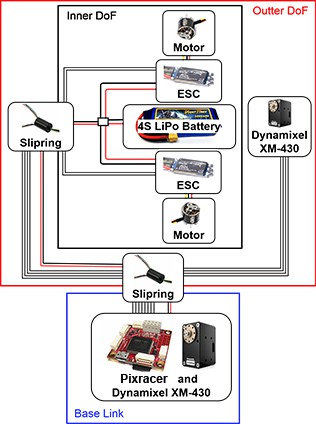

To avoid using two heavy slip-rings on the two DoF gimbal mechanism, we proposed the solution of changing the location of the electric components on the system circuit. Instead of placing the battery away from the rotors and at the geometric center of the UAV, as it is commonly done for most multirotor UAVs, the proposed solution places the battery together with rotors. This approach shortens the wire length for the power connections (mainly from the battery to the ESCs and rotors), leaving only low current wire connections routing toward the vehicle's base and the control boards. By employing the slip-rings in this configuration, the proposed design can use both DoF continuously. This means that the base's orientation does not affect the direction to which the thrust is applied. Additionally, by placing the battery with its wider side along the rotors' axis, the propellers' occlusion effect is minimized. In our design, the dimension of this occlusion is only slightly wider than the motors' diameter.

Joao Buzzatto

Joao Buzzatto

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.