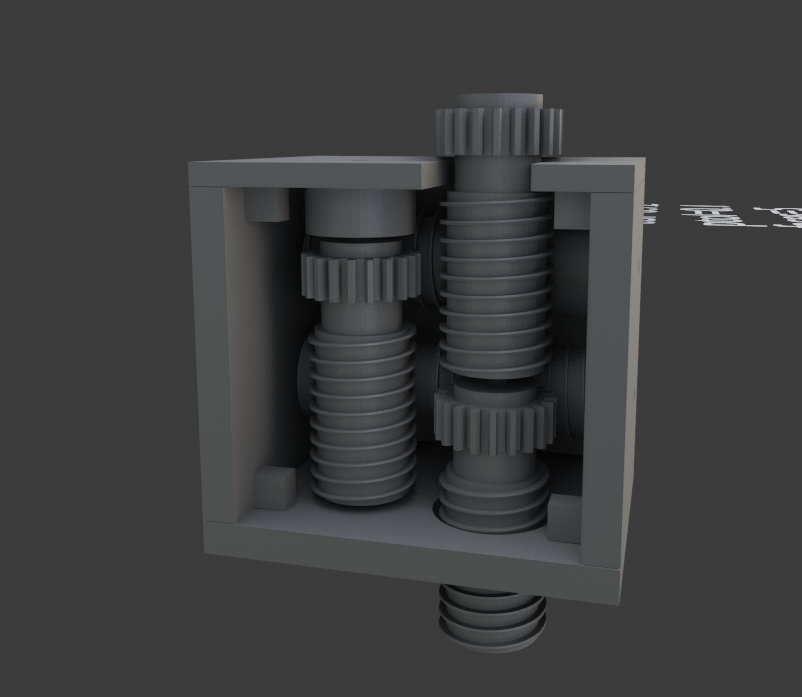

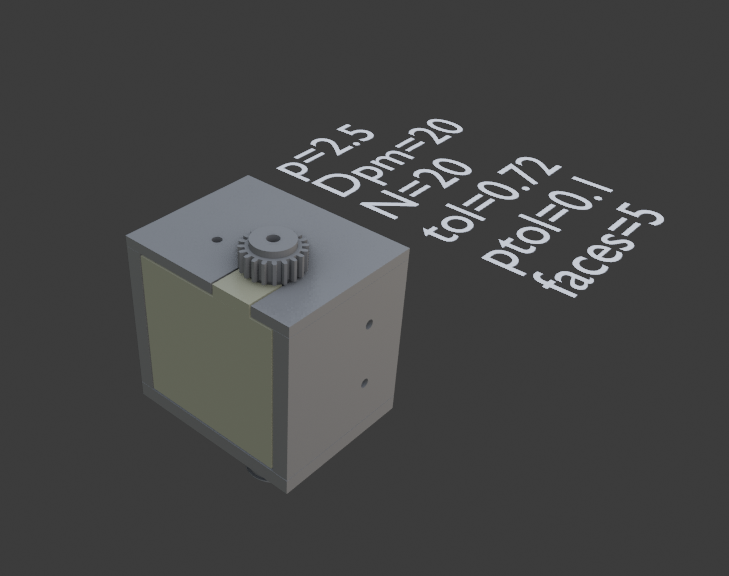

To reduce 1:80 (2.5mm/step)

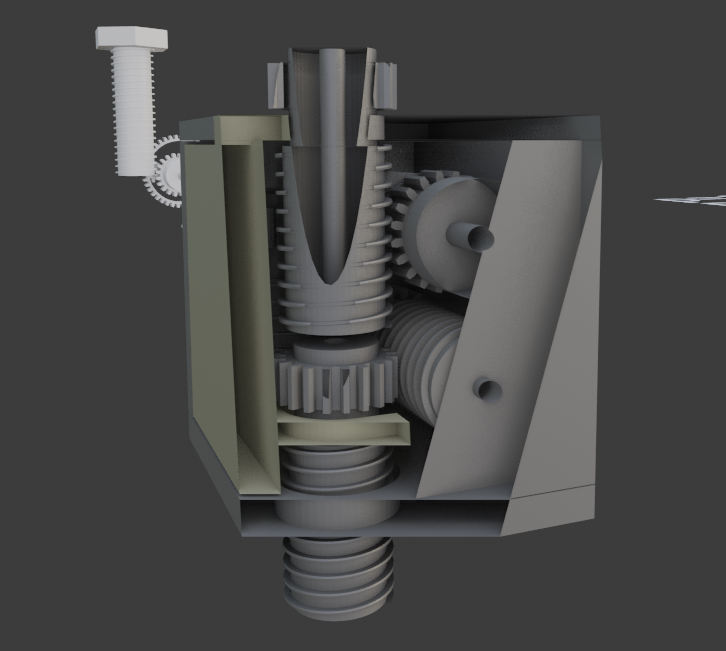

If I need to change direction maybe I can place an output module with some gears or levers to amplify the movement of last gear (no need as much as 80:1 again) and detect that final tiny backlash.

Or ensure the contacts with springs??

-

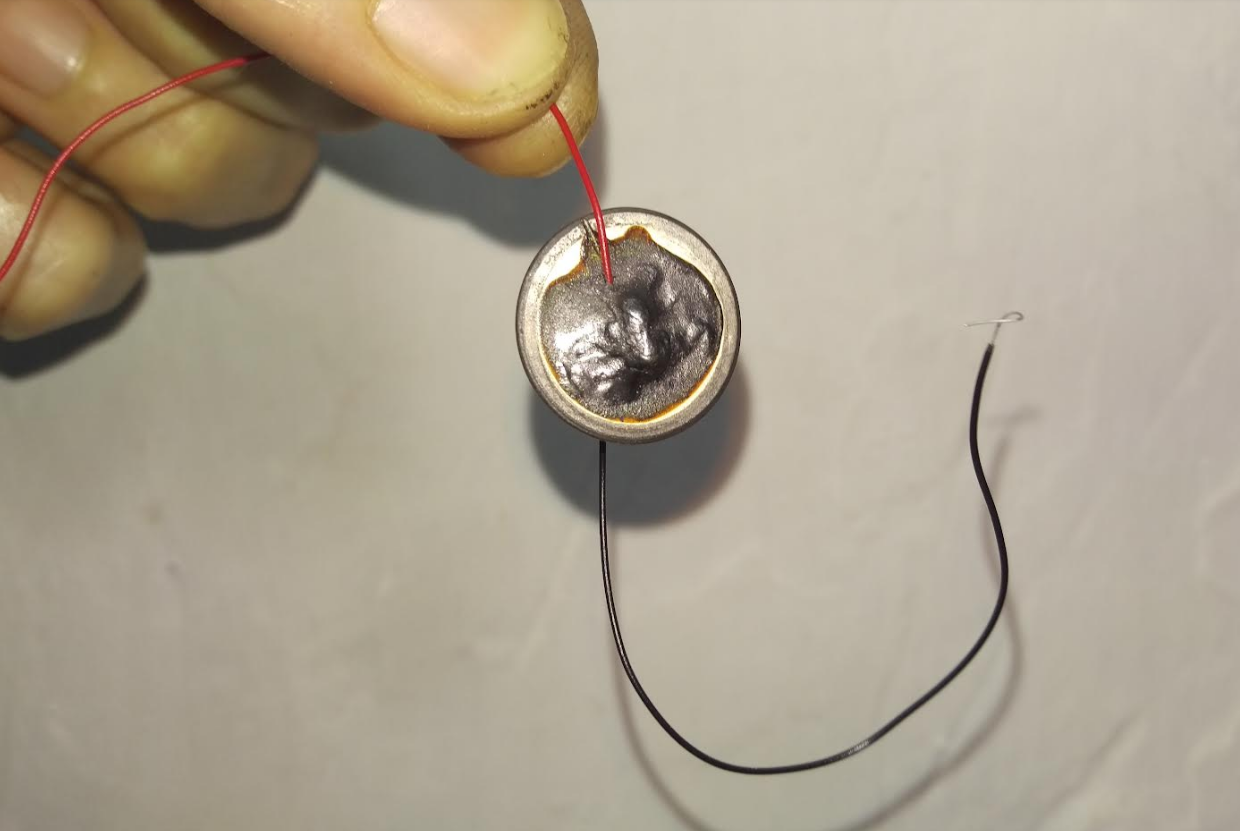

Iodine + Alcohol + graphite to get aglutinant for graphite dust

Let this dry

This aglutinant is serving to me to make some welds where tin can't. It stays very hard and shiny after rubbing with tissue.

And the most important... Stop staining! :D

nice lubrication.

I think now I could even galvanize :D

3drobert

3drobert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Hi Florian. Thanks for clearing it. I had doubts about the relation too :).

what you say is aclaratory for me and help me to understand better

Are you sure? yes | no

Worm gears have low efficiency. This is more or less why they are not back driveable. Stacking four of them in series is probably a bad idea unless you really don't care about efficiency. If you want a self locking gear train one worm gear stage is enough.

I also have trouble to understand how you are calculating the reduction ratio. This looks like 4 1:20 reductions in series. This does not amount to 1:80 (aka 1:(20x4)) but to 1:160000 (aka (1:20)^4). So the overall reduction is much too high. If you really want to get 1:800 increase the input and output gear to 126 teeth and stick to just one stage. This gives a reduction of 1:793.8 (assuming the driving gear stays the same size).

Are you sure? yes | no