Silicone is a wonderful material, it is flexible sticks to almost nothing but itself and has high temperature resistance. Especially the being flexible part plays a big role in soft robotics. Flexibility is denoted by something called Shore Durometer (usually shore for short) and it is absolutely key in this project. Furthermore I would recommend choosing platinum cured silicone, see last paragraph.

Shore Durometer.

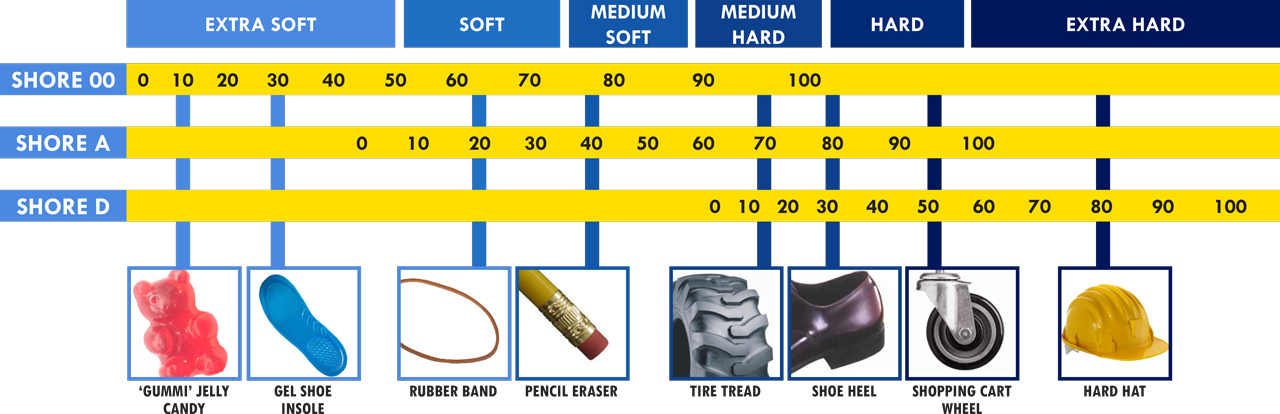

As stated the shore rating of silicone determines its stretchyness. When looking at the figure below we can see that there are 3 major scales namely D, A and 00. Take into account which scale you are looking at when shopping for your silicone since shore D-10 is orders of magnitude harder than 00-10. In general the D scale is unsuitable for flexible robots, since the flexibility starts at tire level, so we disregard them for this project.

What silicone to use when

We need silicone for 2 purposes, to cast the halves of the bubbles and to glue them too eachother. When using the softest of silicones like 00-10 (ecoflex) you need a harder silicone as the glue. When using a harder silicone like A-15 you need to add silicone oil (up to 15% of weight) to make it flexible enough but can use the same stuff to glue the parts. Since the bottom part of the mold doesn't flex you could also cast that part from harder silicone.

Recommendations

Ecoflex 00-10 (from Smooth-on) will give a nice squishy organic feel to the frog cheeks. It is harder to work with since it pours more viscous and catches air bubbles more easily (which is bad), it is also harder to source outside the US. In my opinion this silicone is a more advanced option. I got recommended to use Ecoflex 00-35 FAST for glue but haven't tested it (A-15 works fine for glue as well).

Silicone shore A-8 has a great flexibility that can be inflated well with 6V (at 5V) airpumps, it also pours well and can be its own glue. It is very unfortunate that my supplier offers it only predyed with blue pigment which makes it unsuitable.

Silicone shore A-15 is actually a bit to stiff for inflating but when adding 15% silicone oil it is just flexible enough to be inflated with the 6v (at 5v) airpump. A 12v airpump would be better but requires more power circuitry. It can be its own glue, with or without adding oil.

The path to go is yours to choose, but sincerely look which of these options are easily available for a good price in your region. Since a lot of this is experimentation having the option to order more is worth a lot.

Pigments:

You can use pigments that are specially designed for silicone to dye your bubbles really easily. Dying the top part white diffuses the light from the LED really well and makes for a nice effect. You only need a little bit to color decent amounts of silicone so use a toothpick and add it bit by bit (pigments are also reasonably expensive).

Protective equipment

With our current knowledge silicone is not very toxic so don't be afraid of it. Do use nitrile gloves when handling, pouring and working with it. In uncured form the silicone is a bit more harmful don't get it on your skin or ingest it and all that jazz. It is still not super toxic and does not burn when making contact with skin it just sticks to everything. Make sure you wash your hands when done handling it especially before eating things. Read the safety sheet and do your own research. Don't use latex gloves since the latex can/will inhibit the curing of your platinum silicone.

Cure inhibition

This is when your silicone doesn't harden completely and is still sticky or tacky to the touch. It can happen to the complete part or to only a section of it. Usually when it comes in contact certain compounds (usually containing sulfurs) latex is one of those. You also should not keep tin cured and platinum cured silicone in close proximity since they don't play nice. Or use both (sequentially) in the same mold. Lastly a bad cure could also be the result of bad ratios part A and B or insufficient mixing of them. Read the package if you should measure them by weight or volume and in what ratio to mix.

Platinum vs tin silicone.

I would recommend always using platinum cured silicone for this project. It is the more premium versions and cures and handles better. It also more available in lower shores (I think) just don't buy the tin cured for now since it can only lead to inhibition mishaps if you mix them up. There are some other properties that are generally more favorable for platinum silicone which you could look into if your interested. Just know that there are multiple types of silicone and that you should buy the platinum curing one.

Inne

Inne

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.