Desiccant placement has been a long time problem, but newly aggravated by more air leaking into the container than there used to be. Dumping it in made a mess after it got wet & the filament had no improvement in print quality after 4 days.

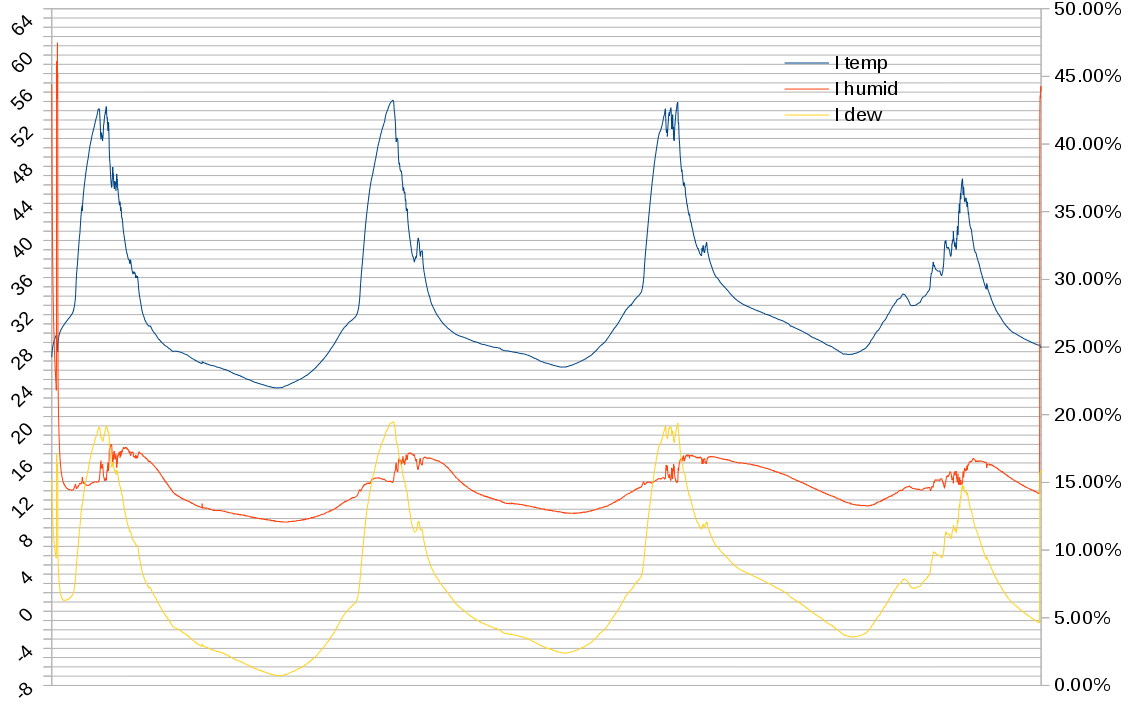

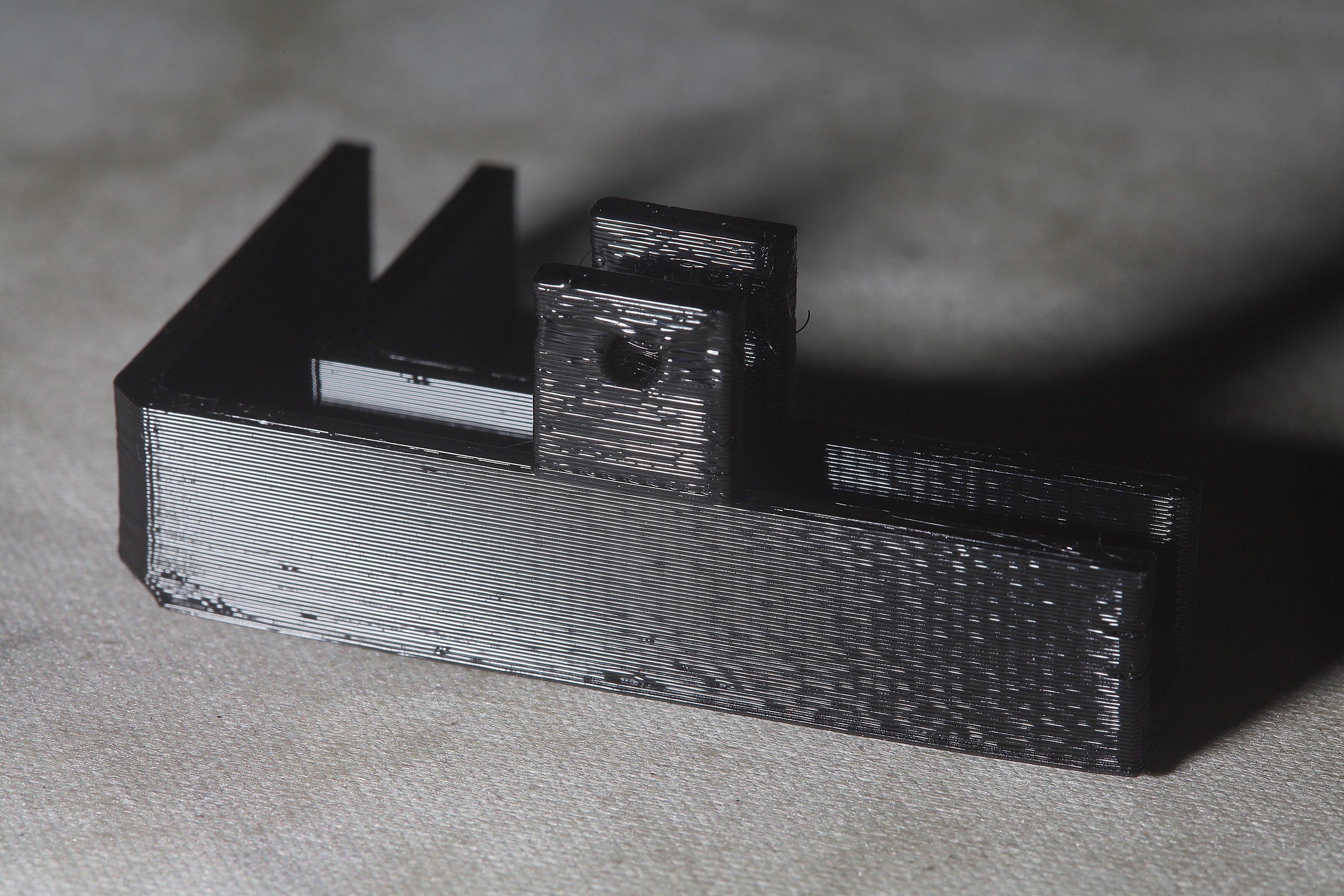

Humidity went up as the desiccant saturated. Lions noted the saturation of a column of desiccant goes 2cm deep & leaves everything else dry. The ideal container would be a tray with <2cm depth. A bottle is not the ideal container. A sphere would let wet desiccant leak out. It has to be water tight on the down & side facing sides. For the current solar container, it would have to be a rack of 2cm deep trays with air passing between the trays. It's a bit labor intensive so a better system is going to be a much wider than necessary container with enough room for a single desiccant tray & filament to be side by side.

For storage containers, lunch meat containers come to mind. Coroplastic things could elevate the filament over the desiccant tray.

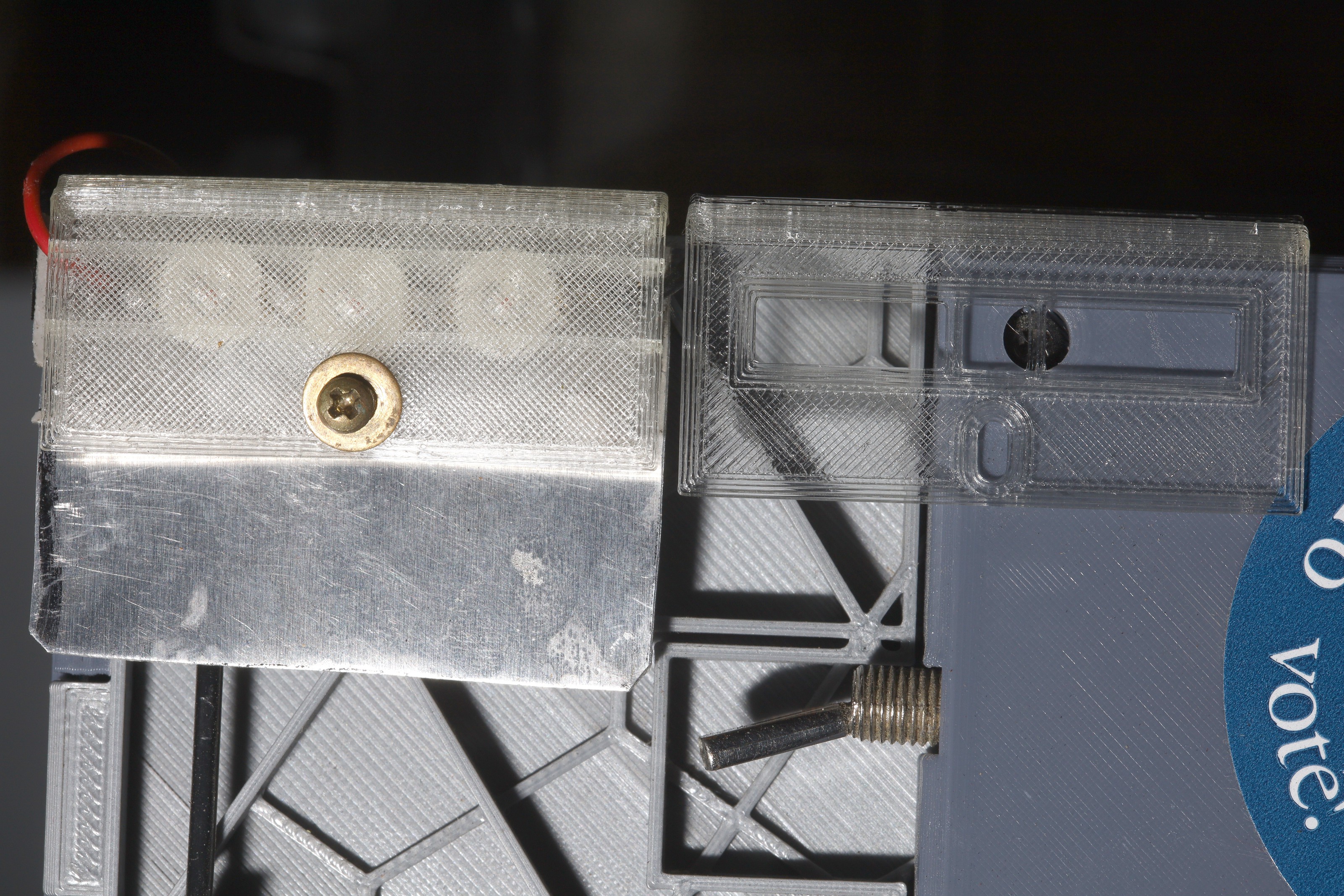

The next step was just making a desiccant tray out of a very old tupperware with paper towel to keep it from spilling.

The optimum container for side by side placement was a 1.1 gallon Rubbermaid.

The bigger problem is the container longevity. Container longevity & getting signals in the container without creating holes is a super hard problem. There are concepts for inductive power, but getting enough power for the fan is tricky. For now, the fan & sensor were abandoned.

A few days of this yielded perfect parts. Results seem to take just 1 day in the sun with no fan.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.