Reviewing the source code, it's hard to believe this journey began with a recycled inkjet vacuum pump, a fuse to prevent it from stalling, dual I2C drivers.

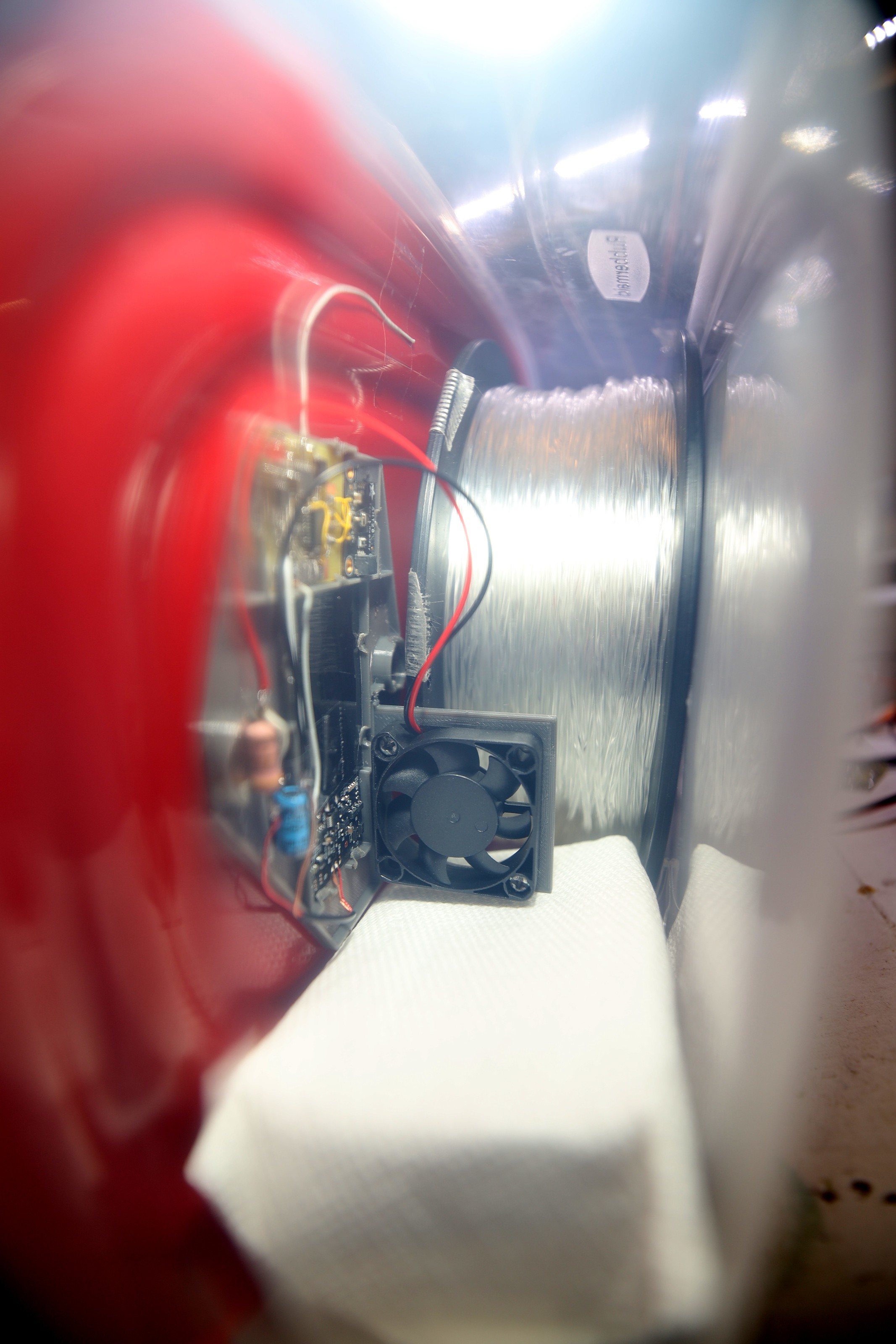

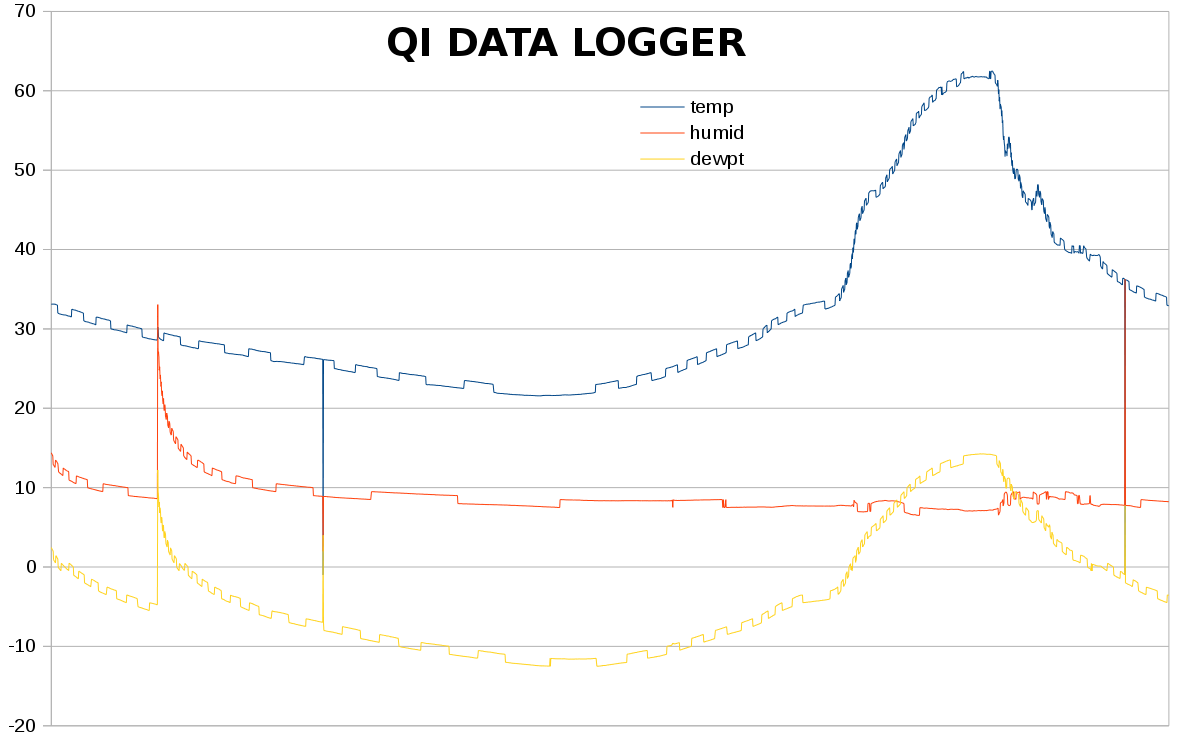

With the inductive power, there's no longer an easy way to measure external temperature & toggle the fan based on a temperature difference. The fan has to always run. All the brain is for is logging data. It's the only way to know if the container is leaking or the desiccant is dead. There are bluetooth sensors which would do the job with a lot less work.

https://www.adafruit.com/product/4881

But lions being what they are went ahead with a custom solution. It would send to the same apartment server that handles the desks & weather station. The success rate of any particular idea is so low, it actually ends up saving more than the cost of the commercial solution to build it out of bare chips.

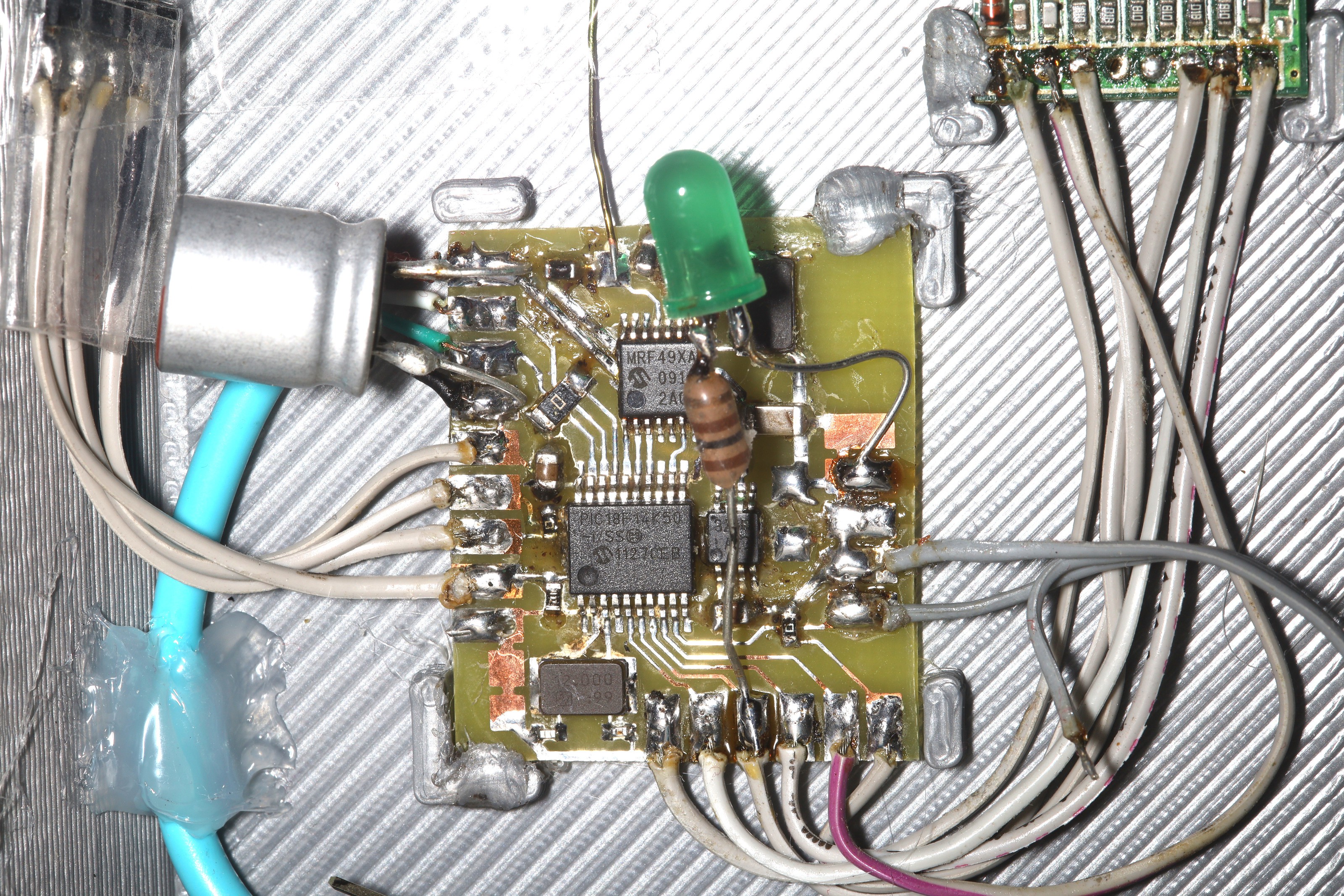

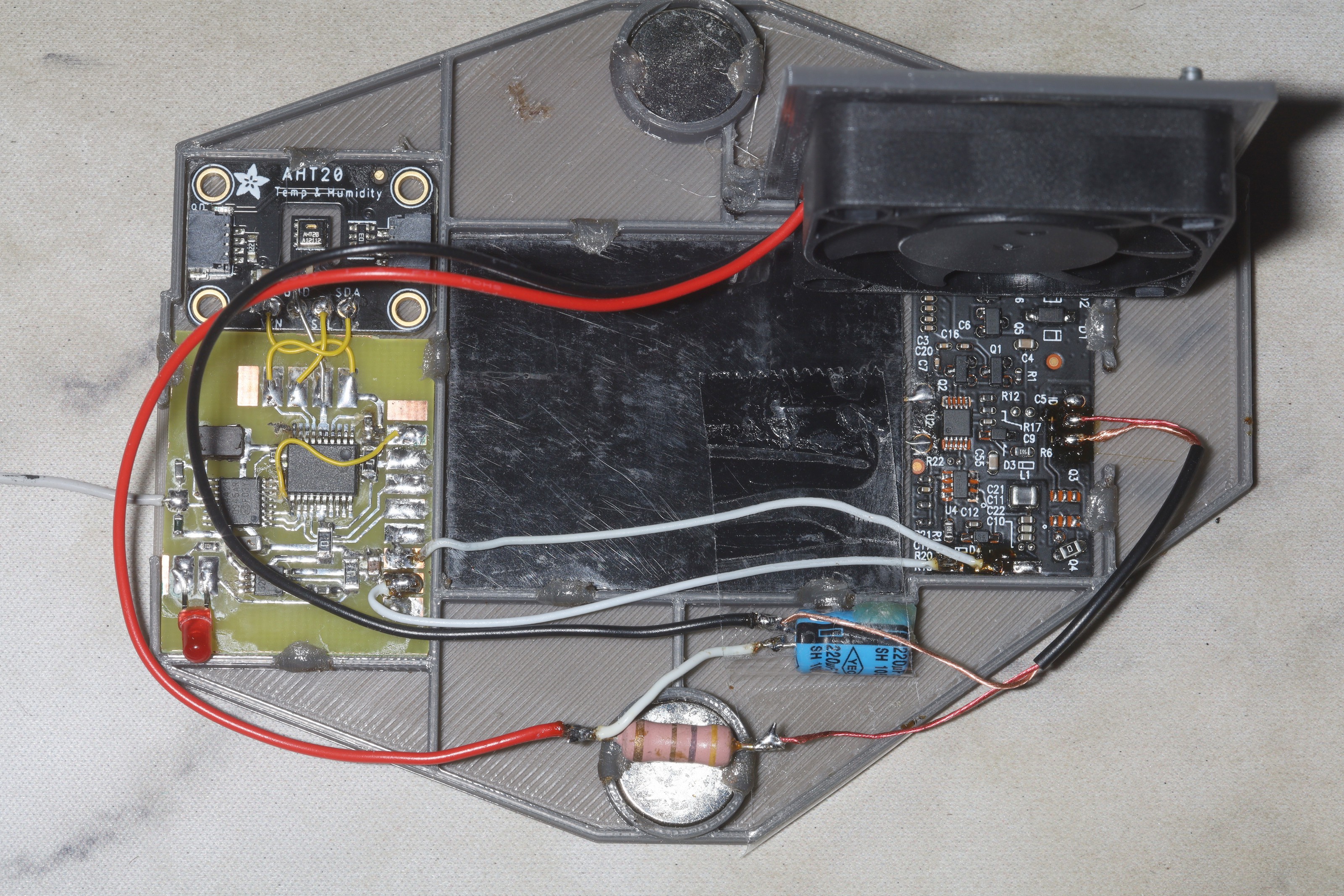

The very last 18LF1320 from 15 years ago went on a board. To stabilize the clockspeed in the heated container, it runs on the clock output from the Si4421. This ended up being a very janky operation. The 18LF1320 can't switch from its internal clock to an external clock.

The trick is if the Si4421 gets into a dead clock state, it needs a power cycle to reset. Then it generates a clock by default. Many retries are required to get the Si4421 out of a dead clock state. Another trap for young players on the 18LF1320 is the serial port receive pin can only be an input when the serial port is on. It's not independent of the TX pin. Finally, if the TX pin fights the radio because the radio is in receive mode, it pulls down the RX pin, copying the radio signal to the RX pin.

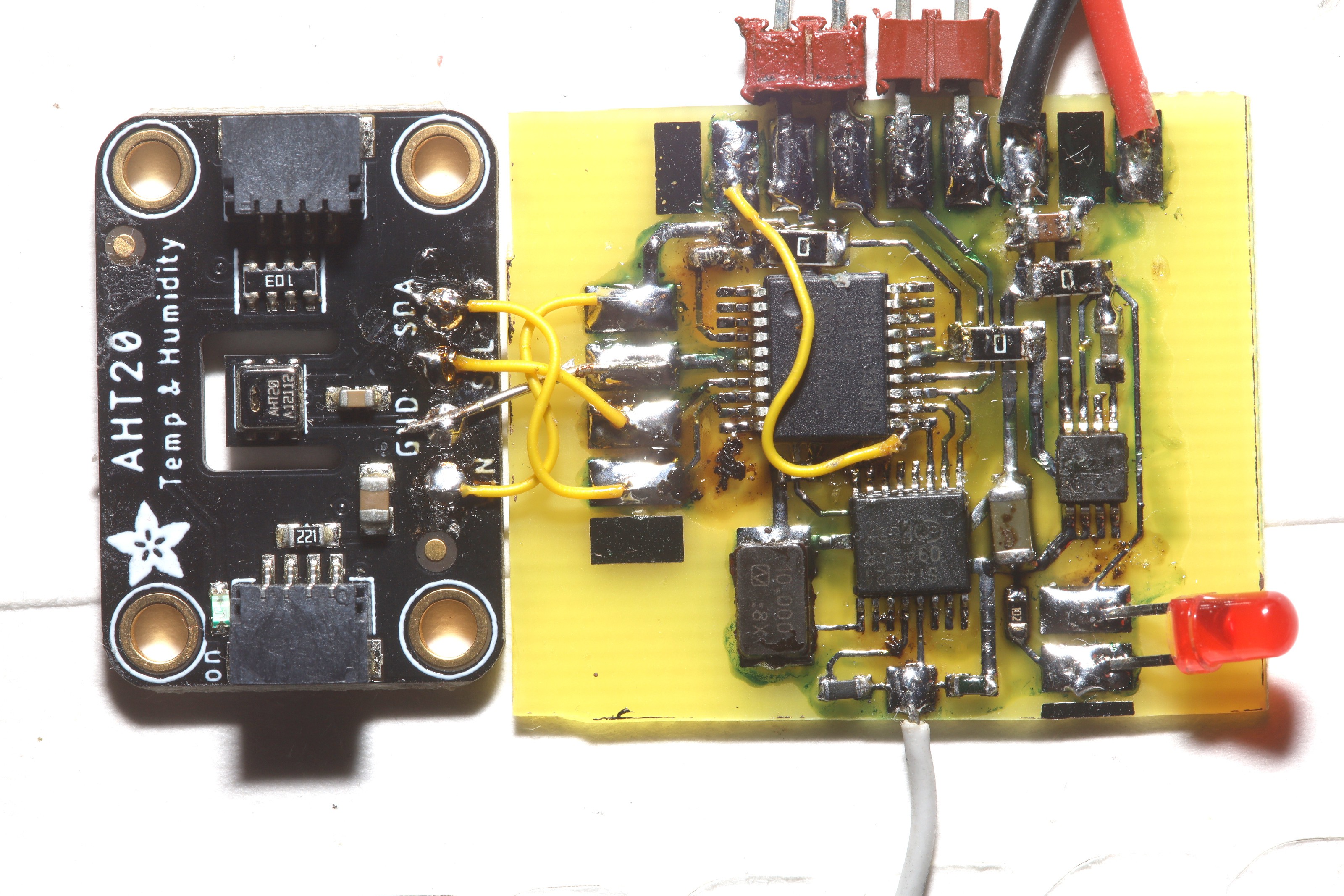

Would have been easier if the jumper wires were straight across, but mounting the AHT20 at a right angle would make it vulnerable to vibration.

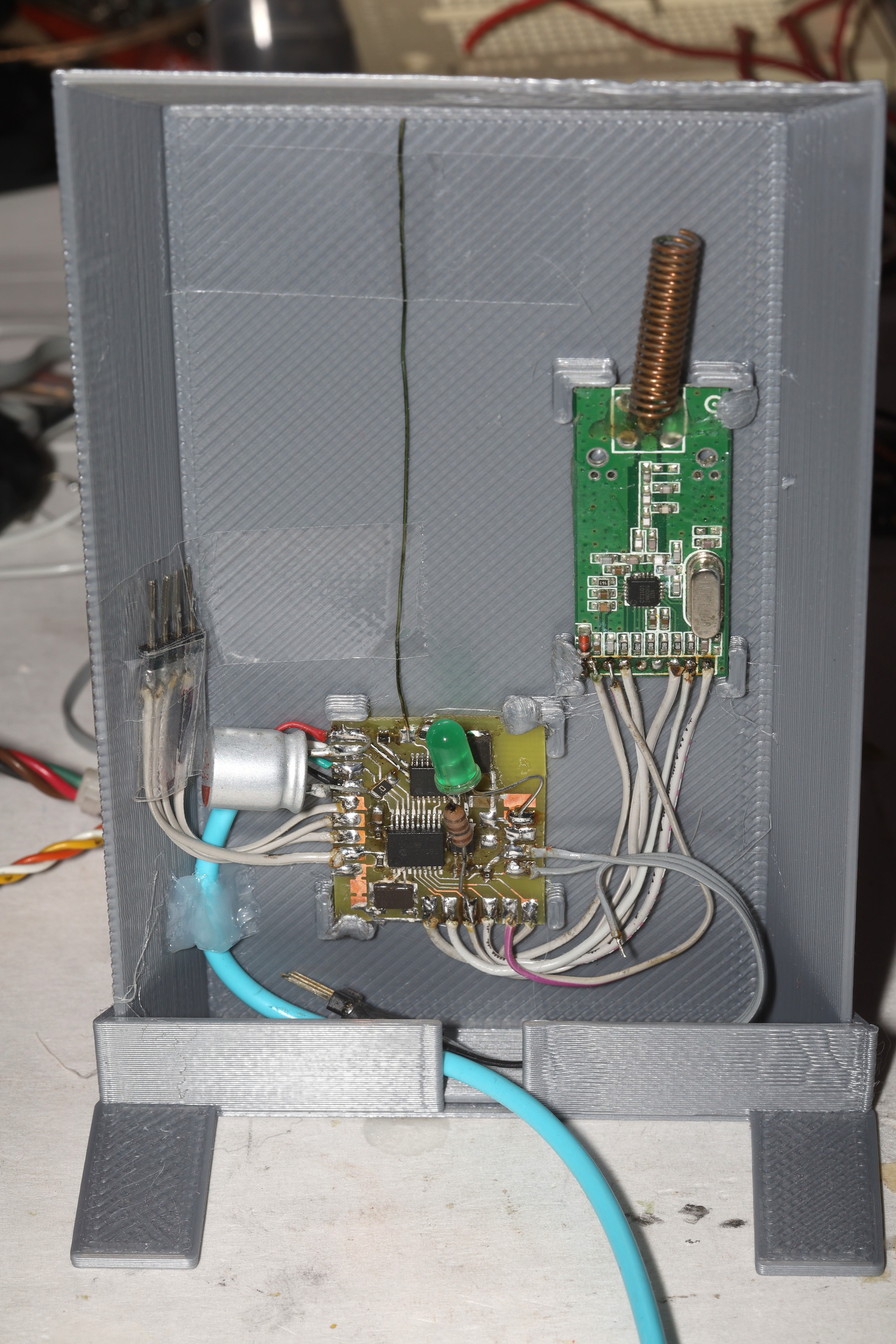

The mane router upgrade was an LED for received desk code. It's suffering from extreme packet corruption but desk 1 also seems to miss a lot of wifi packets. It may require a 2nd microcontroller for just decoding the 433Mhz signal.

Adding filament drier data to the apartment server was a big job, it's remarkable that the exterior weather station still works, given its condition. There is a desire to upgrade all the radios to 100kbaud, but this would make it difficult to parse the 433Mhz signal in software.

A few hours with this showed the new container getting a lot hotter than the old container. Less leaking & more exposed area got it to roast.

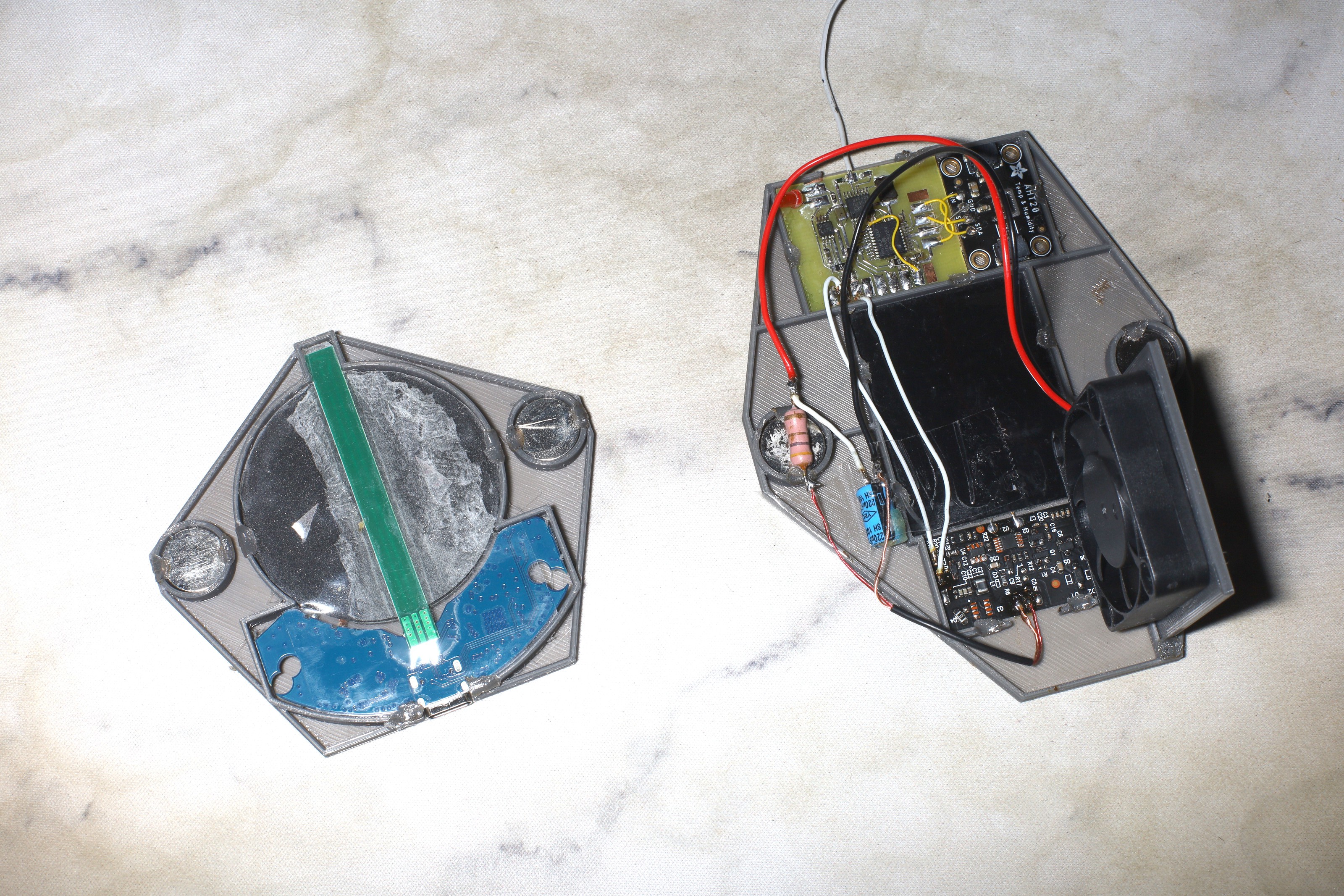

The 1st data logging attempt had a few problems. The mane problem is the lid not being flat. The only place for it is right next to the filament. The antenna can't be extended & the fan has to be right next to the filament. The signal still reaches the router.

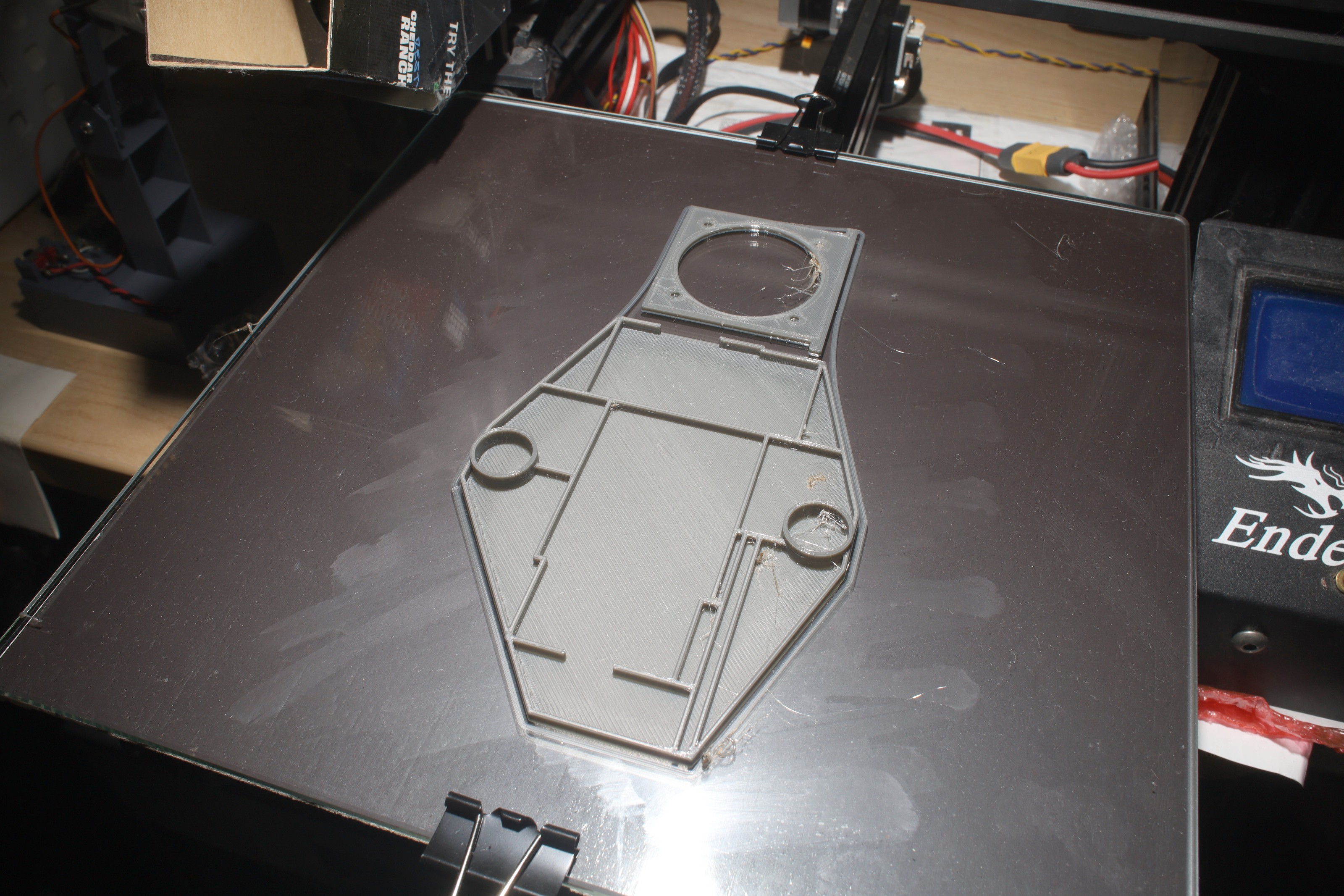

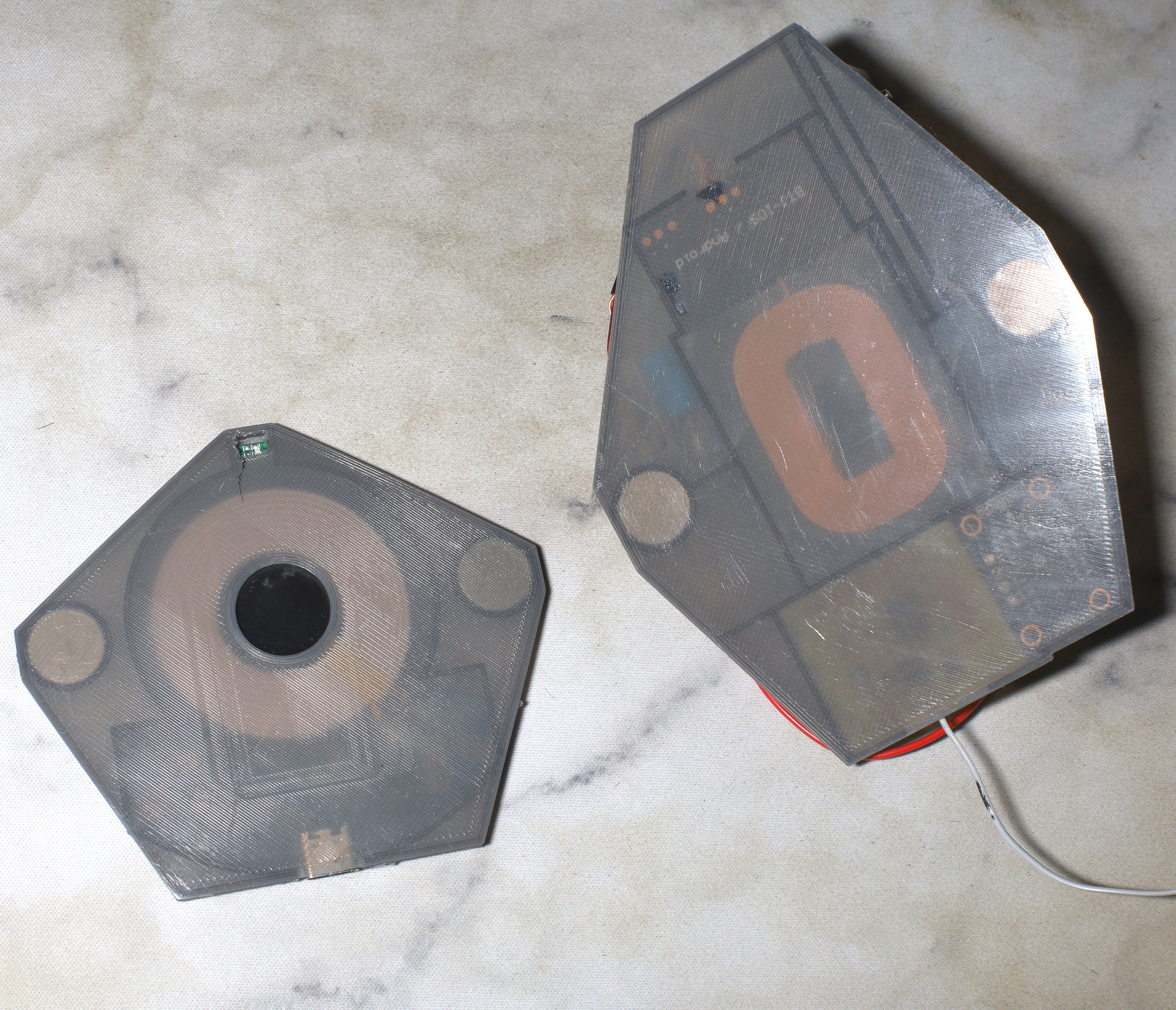

The fan has to go in the middle on the opposite side. The magnets have to go right next to the charger coil & diagonally. The RC circuit needs some fixtures.

If the Qi receiver is folded over & double sided taped together, it should free up more space.

The Qi receiver still needed a 5 ohm, 220uF RC circuit to power the fan.

A big problem is the desiccant spilling everywhere despite being covered.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.