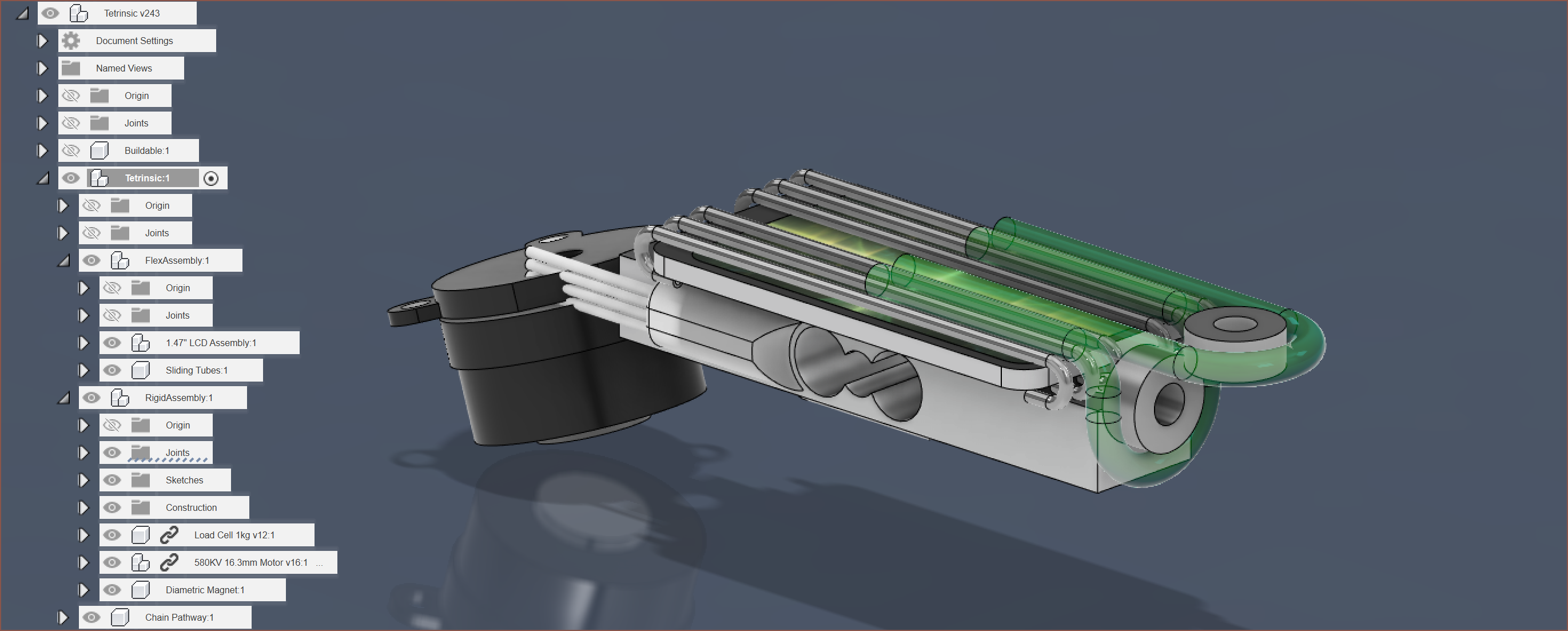

This took somewhere between 7 - 9 hours to get to; it's a good thing I spent the time setting up #TrueTent [gd0143] . You have to realise that all designs since Tetrinsic 2.0 were more like detailed 3D sketches, and that there wasn't as much concern for file cleanliness or the pathway of the chain.

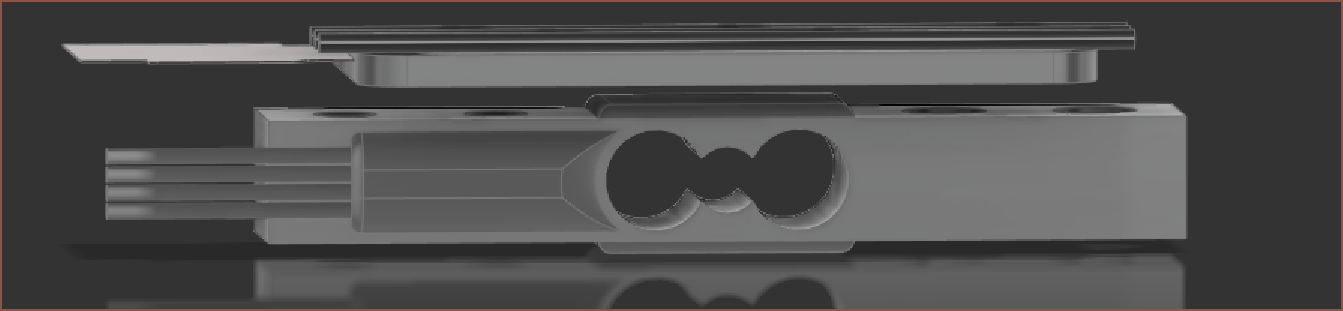

To start off, since #Tetent TimerSpy [gd0136] is being shelved until further notice, and that #Tetent [gd0090] has better ergonomics the longer it is, I decided to ease manufacture by not cutting the load cell at all:

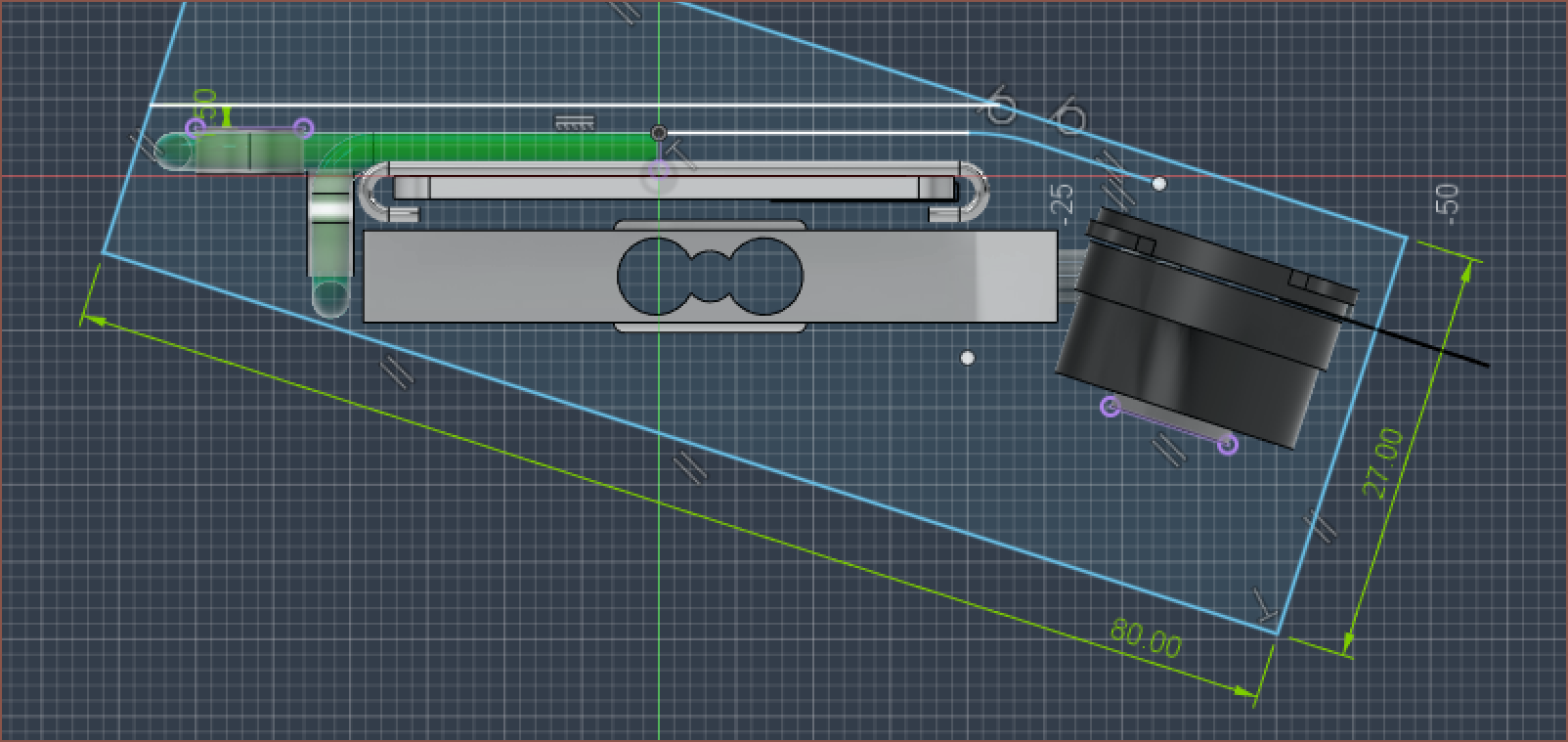

I found out that there's an all new environment option in Fusion 360 called River Rubicon, which is a rather nice dual shade of blue:

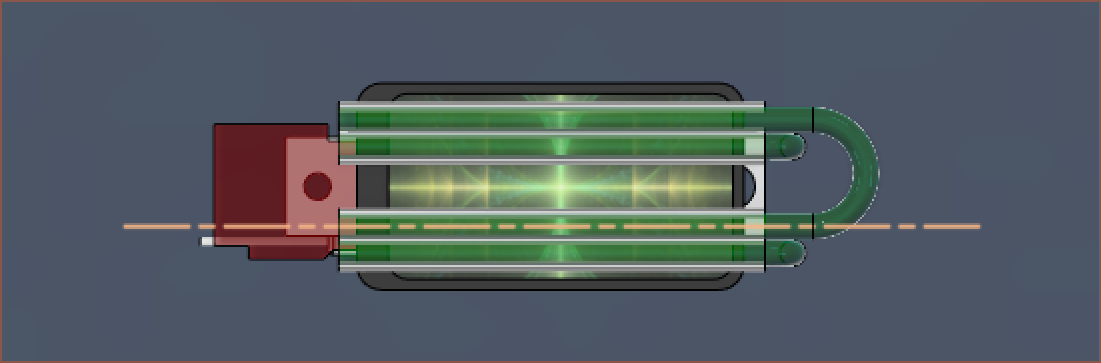

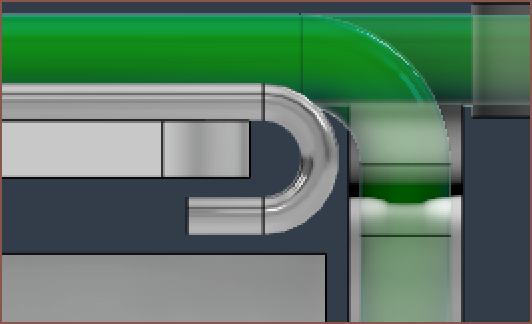

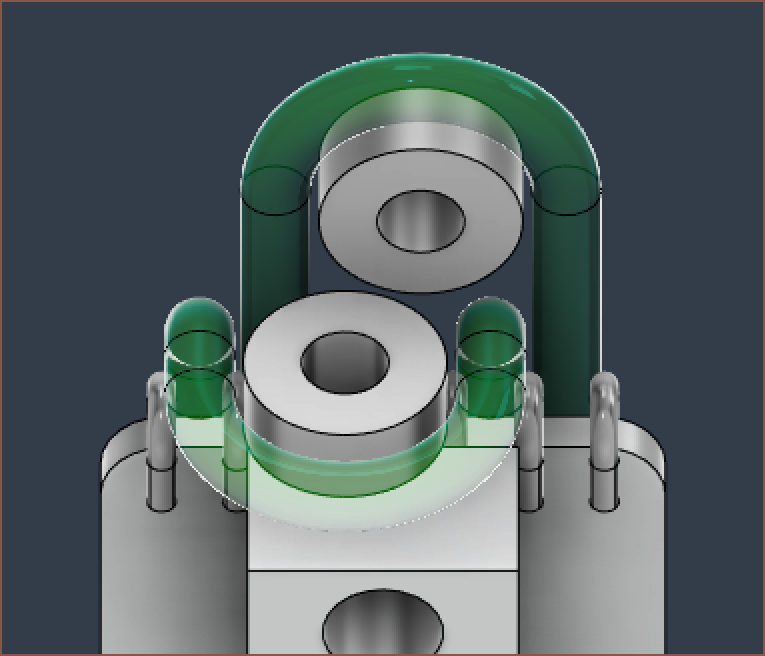

Then I had to have a long and thoughtful computation on how I was actually going to route the ball-chain, and I decided to try and actually do the chain swap on the bearing side so that the motor side didn't have an excessively complex looking junction.

Very conviniently enough, the diameter of that curve is a fraction of a millimetre larger than 7mm, allowing me to use 683ZZ bearings. I probably should've checked, because these are actually some of the smallest bearings commercially available (that aren't something like £1 each).

I should also mention that I've decided to use 2.4mm chain since I've got that with me already, meaning that there should be no suprises with the feel or durability of the final assembly.

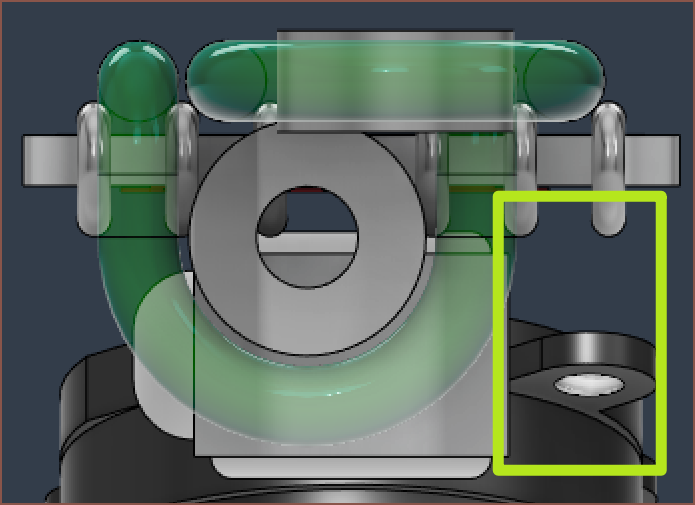

I've routed the chain like this so that the right side (of the image below) is as free as possible, should I need the space for something:

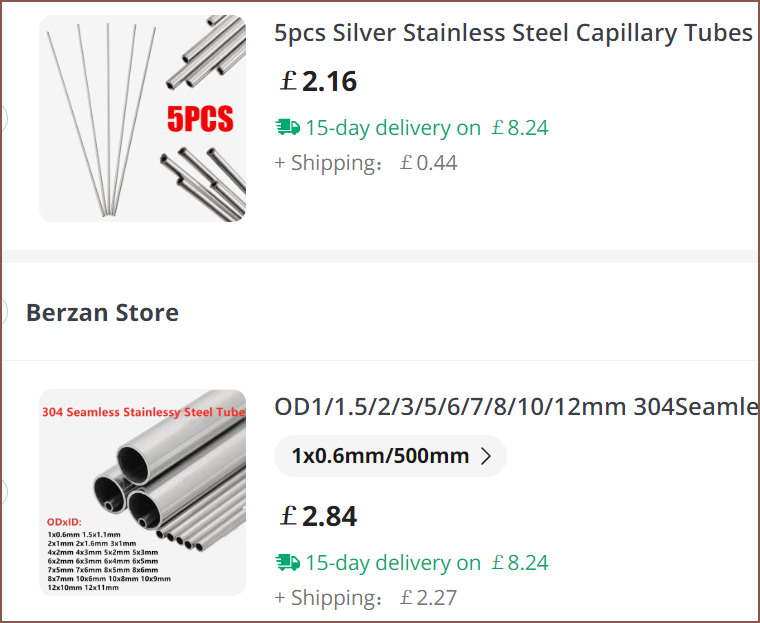

From this angle, you may also see why I've had to bend the 1mm steel tubes: there's not really any place to grab them if they were straight. I don't have any bending knowledge, so I'm going to assume to keep the radius equal to or greater than the diameter of the tube:

I'm also not much of a fan of this tube price, seeing as there are sellers that sell (specifically) 3mm tubes for a fraction of the price.

From my calculations, each one of the 6 tubes in the design is 45.7mm, requiring just under 275mm of length per Tetrinsic.

Back to the bearings, I've got to figure out a way of mounting them. I might use a small ring to shrink the ID from 3mm to 2mm.

The entire design looks to be on track for an 80 x 27mm footprint. This is an increase from the 66 x 24mm footprint in the concept design.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.