The current solution... may fail, due to:

- turning radius requirements of the 3.2mm ball chain

approaches the motorised sprocket diameter.

So I've implemented some tweaks and learned a few things.

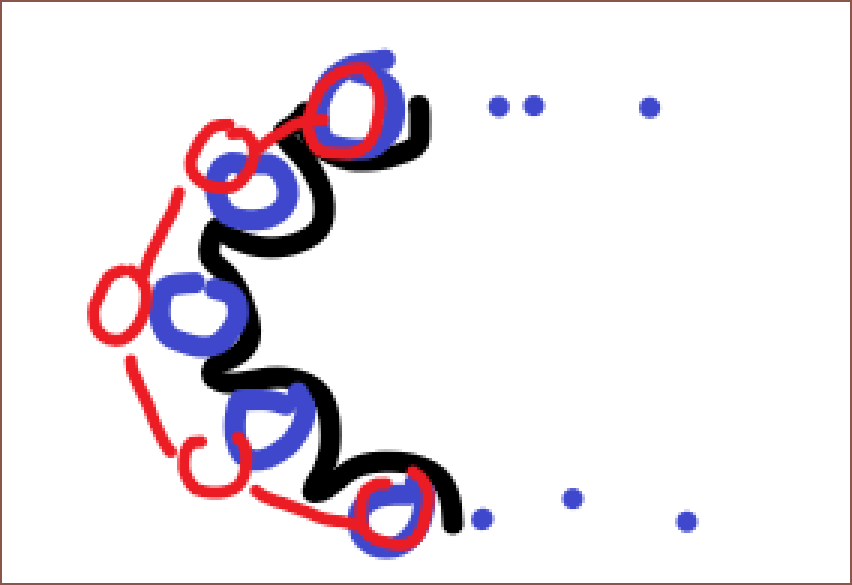

Firstly, unlike what I assumed months ago, the chain won't actually slot into the sprocket teeth if the teeth are too close together. Instead, the first and last balls slot in and the rest kind of hover in an arc:

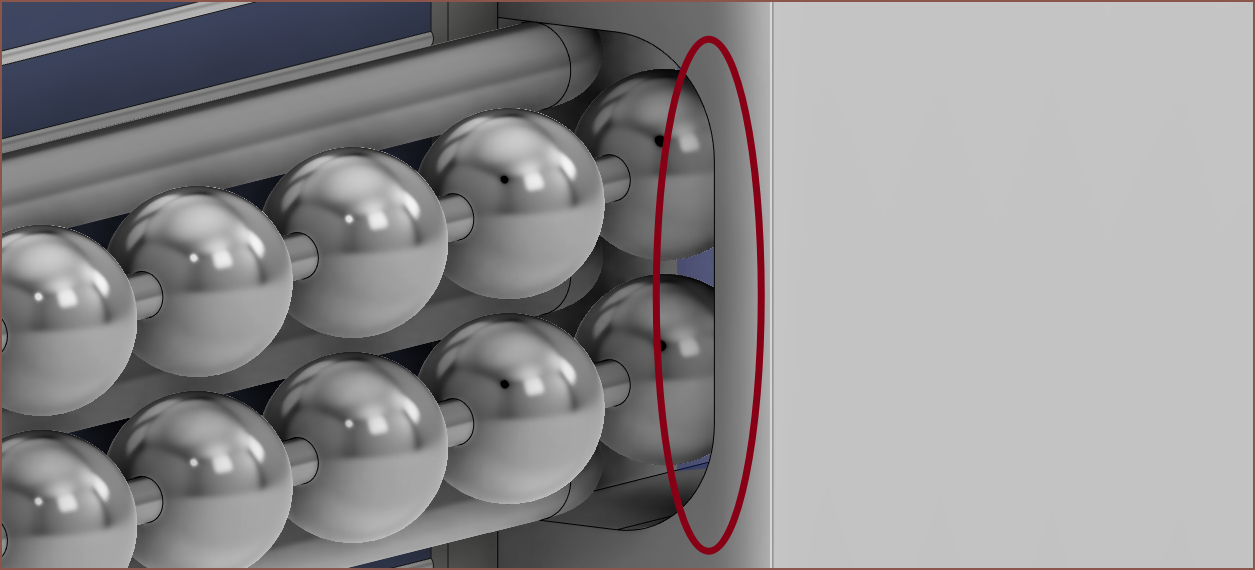

Secondly, its starting to seem that the 3.2mm chains natually tensioned turning radius is closer to the 16 teeth motorised sprocket than the 10 teeth unpowered front sprocket. It kind of makes sense now that I've actually got prints in my hand and the small bend does seem ambitious. This issue might be mitigated since there'd be a roof over the sprocket, but what is likely to happen is that the chain catches on the top edge of the entrance hole (see below), especially when in different orientations.

Taking costs and utility into account, it would overall be more beneficial to use dual motors. I know what I'd need to change in the file, but there's quite a few changes that would need to be made. I'll also have to assume that I need to be able to spin up the motors so that I can get both sets of poles aligned before I lock their rotations together via the chain.

The bigger issue is that the solution would cause the current Tetent concept to fail, mainly due to Finger5 as per usual. Sorry Me In The Past, but it is not safe to upgrade now.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.