Here's my first solar concentrator build. The aim for now is just to stick a thermometer in the pipe and get an idea of what sort of temperatures can be achieved 'dry'.

The main problem is that the self-adhesive mirror sheets won't work for the mirror surface, they crinkle too much which reflects the light all over the place. I'll try mirror-chrome vinyl wrap sheets instead. I might have to deal with the rust to make that stuff stick though.

Otherwise it came together alright. The design is intended to be simple and cheap to construct. The pipe is secured as pictured in a wooden mount for insulation from the steel. This mount has slits cut into it so that it can be slid to the optimal position, then secured using bolts that clamp the slit shut. This seems to work quite well.

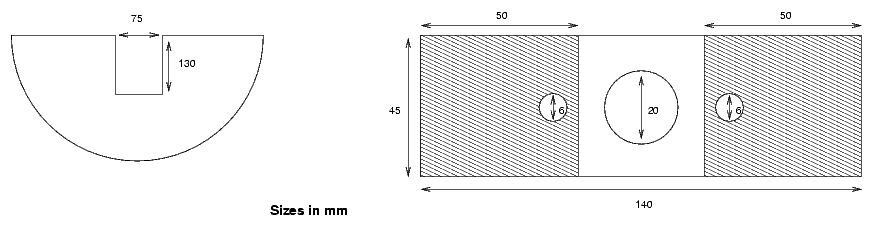

The design for the pipe mounts is shown here, made from an 18mm thick plank of pine:

The entire construction process should be documented step-by-step later once the design has been finalised. For now, some basic notes:

- The sides of the drum were cut using a jigsaw, avoiding the steel rings at the ends. This worked OK, but wore through two jigsaw blades. A cheaper alternative might be using a drill-powered nibbler tool.

- The end rings were cut in-line with the slits in the sides using an angle grinder, so that the drum now parted in two.

- The gaps/slots in the end plates for the pipe mounts were cut using tin snips.

- The mount pieces were cut from a plank of pine, taking care that there were no splits or knots in the timber. The 6mm bolt holes were drilled, then the slits in the ends were cut using a hand saw. Exact straightness wasn't necessary for the slits. The hole for the pipe was drilled using a forstner bit, and widened slightly with a round file until the pipe fit through snugly.

- The end pieces were slid individually into the gap cut out in the ends of the drum, and the pipe was then inserted through them. The friction without the bolts is enough to hold the pipe in position for testing, but their addition and tightening locks the mounts in place much more securely.

Reflector Shape

An optimal design, such as others documented online would use a parabolic reflector. It may be possible to form a parabolic shape from an oil drum by cutting out a section of the side and both the end walls, then bending the hard circular rims at the ends into a parabolic shape. This may be tested later, but it's hoped that the semi-circular trough will be good enough that the ease of construction overcomes the sub-optimal optical characteristics. Basically, quantity over quality, so that losses in the optics are overcome by easier construction of the semi-circular concentrators, allowing more to be produced to compensate. Plus you get two semi-circular concentrators per drum, instead of one parabolic one (maybe).

It may also be worth investigating using a vertical absorber plate rather than just the pipe alone. This paper suggests that a semi-circular solar concentrator can in fact be more efficient than a parabolic reflector in this configuration, and without the necessity for solar tracking.

Pipe

Also known as the 'receiver tube'.

Size for the moment is mainly a guess, with other designs online using a variety of different diameters, usually while quoting some maths that I don't really comprehend. I'm expecting to rely on experimentation to work out exactly what's right for this. Obviously for the final design the expected steam pressure will necessitate a certain minimum pipe thickness so that there is sufficient strength.

Another big consideration is whether to use evacuated tubes. These are specially designed glass tubes with smaller solar collector pipes running inside, and a vacuum in the gap between. The vacuum prevents heat loss to the air. These are made for solar hot water heaters and available individually, but unsurprisingly they're expensive. As solar hot water systems are quite common in Australia, it may be possible to get hold of some cheaply that have been removed from an old rusted-out system. Obviously the design would be cheaper/easier to replicate if they weren't required though.

This webpage demonstrates super-heated steam generation with solar concentrators using evacuated tubes.

The pipe may be painted matt black to maximise absorption. Perhaps look at paint for car brake components as this is designed for high temperatures?

Mirror Coatings

This is the most immediate thing to sort out because as mentioned the self-adhesive mirror sheets don't seem suited even for testing.

Chrome vinyl wraps supposably provide a mirror finish, and are designed to be attached smoothly to curved sheet-metal surfaces. They are also supposed to be weather-proof, though looking around online it seems six months might be the likely lifespan outdoors - perhaps extendable by painting over the top with clear coat spray paint?

Example product for sale

More expensive, but supposably better for avoiding air bubbles

Chrome spray paints are available which contain chrome-plated metal particles, but apparently it's not possible to achieve a mirror finish with these.

Actual spray-on chrome plating kits are also available, but very expensive.

Finally, the drums themselves actually have a reflective surface inside, though I was disappointed to see that this had been painted over in the drum that I used (though still visible where the paint has flaked away). This doesn't look to be reflective enough though.

Drum

The one I used had a few dents, which not only mess up the angle of reflection from the mirror surface, but also make for points where rust starts.

The paint on these is very poor, after all they're designed to be just single-use. Besides clear-coat over the mirror interior, the outside will need to be painted as well. Removing the old paint might be done with paint stripper, or using a sand blaster which would remove rust as well.

What about the energy storage bit?

I'm still reading up on all the physics around that at the moment. The solar concentrator will be needed in any case so it's worth making a start on that first. Plus a simpler and cheaper solar concentrator design is worthwhile in itself, even if it's just for the usual stuff like heating water or cooking lunch.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.