Well It's too late for the HackADay prize, but I finally had a go at applying a sheet of Chrome vinyl wrap as an alternative to the disappointingly crinkly self-adhesive mirror sheets. The mirror sheets were left on at one end for comparison.

I did a pretty rubbish job with my first wrap attempt, wrinkles and air bubbles everywhere, but for this it doesn't really matter. Where it went on properly it conforms to the drum surface far better than the mirror sheets, which is the main thing. Although it's also self-adhesive, the instructions say to use a heat gun to set the adhesive (I presume), so I borrowed one and used it at the 250degC setting. Note that the wrap shrinks a bit when the heat is applied.

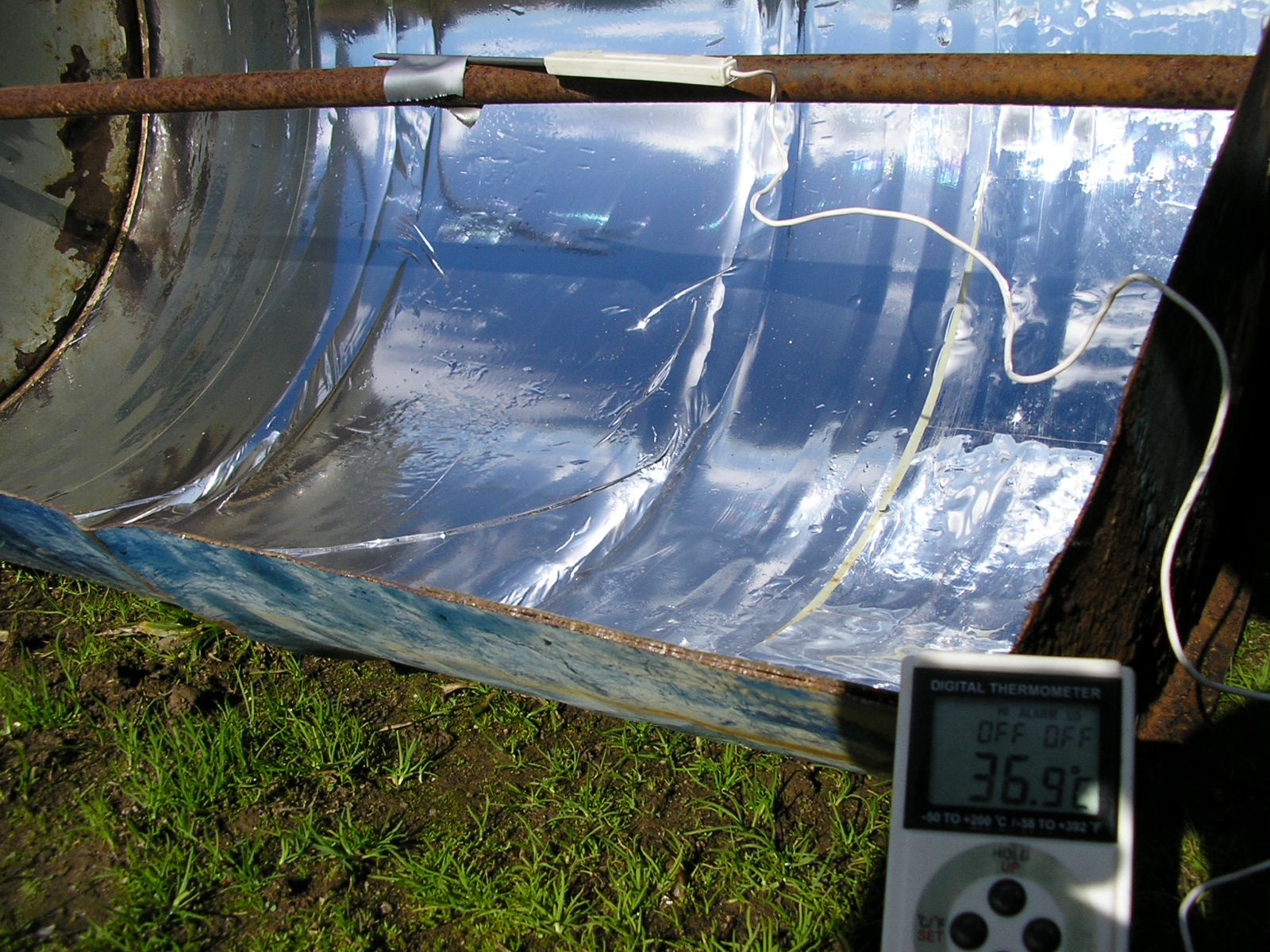

The sun was out, but being late autumn (in (southern) Australia) it didn't have that much bite. Still, the aim is naturally for this to be usable year-round. As shown in the below image a peak temperature with the concentrator pointed at the sun was 37degC. Ambient temperature measured with the same thermometer in the shade was around 16degC, so there was enough heat for a 21degC rise in the temperature of the pipe. Note that the excess length of the pipe beyond the concentrator acts as a heat-sink and probably reduces the achievable maximum. For the purpose of boiling water though, it was hoped that a greater rise would be observed, though connecting multiple concentrators together in a line should increase the temperature.

The paper on semi-circular non-tracking solar concentrators describes a vertically-positioned collector surface which is as tall as the radius of the semi-circular reflector. To see how this might improve upon the above measurements with the bare pipe, a rectangular section of galvanised sheet metal was cut out and slits were cut, through which the pipe was threaded. The result is shown in the below image. Though increasing the collection area and theoretically avoiding the need for tracking, this larger surface area will inevitably also act as a heat-sink dissipating the collected heat away from the pipe and into the air. Unfortunately by this point in the day it had become quite overcast so it couldn't be tested.

The new rectangular collector surface was quite reflective, so a search for some dark matt paint turned up this rather ancient tin of blackboard paint. This is designed for application on wood, but seemed good for a test because after all what's more matt black than a blackboard?

The paint wen't on alright, though after drying there was some cracking, which isn't surprising. Here it is left to dry overnight:

Unfortunately the winter weather set in early this year and there really hasn't been much break in heavy cloud and rain over the days since I finished that on Saturday. In practice of course it needs to work over winter too, but with weather like this that is looking like a bit of a stretch.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.