Today, I saw this Hackaday article comparing the differences between a plain metal bed, the fancy etched beds from Anycubic and magnetic beds, before talking about how they haven't used thier resin printer as much as they would've liked due to the mess. Man, if only there was some project somewhere trying to tackle that problem plaguing personal photopolymerisation printers... 🤭😂

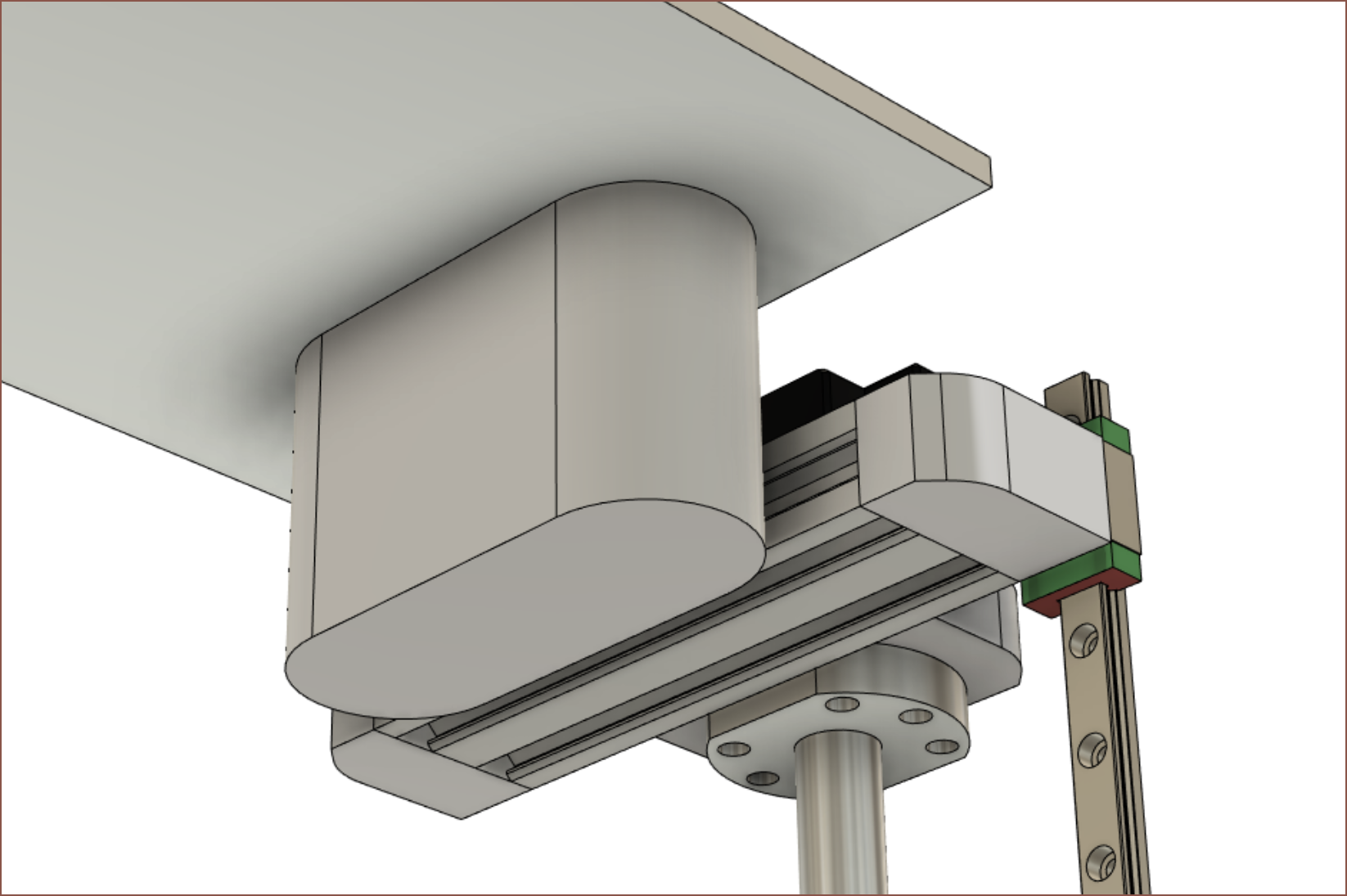

I had a feeling that things were going to be tough with removing the part from a plain bed than with a flexible plate, but also didn't really want to figure out how to make a 500+mm bed removable.

The aformentioned article links me over to this article on a DIY bed. I'm suprised that all the magnets would still be level enough to pring on. Perhaps the required tolerances for resin are lower than I'm expecting. One of the comments makes me aware that blue spring steel exists:

The author of the article has a hypothesis that the more reflective the bed, the larger the elephants foot. For the Suspense, another reason why a reflective bed isn't recommended is the possibility of enough UV light reflecting from the roller assembly and to uncured resin on the film above. A layer ontop of the cast tooling plate would also help because:

- a replacement would cost some £57 delivered and

- a surface raised from the bed means that

- the roller doesn't have to extend as far to clean up resin that squished onto the first few layers (contact area could be 515x168mm instead of 530+) and

- the bed mount screws can be closer to or even underneath the print area without resin seeping into the heads.

FDM rubber flexible sheet? A magnetic sheet printed on FDM or those cheap looking flexible beds for them? It works?

I think it's the latter. That works? It's printed on a raft, so perhaps you can't print straight onto it. It is cheap and a dark colour though, and I've got loads of space under the aluminium bed to put in stronger magnets if needed whilst having a flatter and harder surface under the "rubber magnet" with yet another one.

[E1: 00:22 22 july] I did some searching around on the main 3D printing discord and it sounds like magnetic beds are still a bit of a hit and miss. Also, to address some of the points in favour of magnetic and to eliminate having to drill holes into the cast tooling plate, I've thought of an adhesive based approach:

This means that the bed is now 515x168mm which will be cheaper. This also gives me a bit more room for the cartridge assemblies.

This means that the bed is now 515x168mm which will be cheaper. This also gives me a bit more room for the cartridge assemblies. kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.