For some reason, I don't feel like physically modelling the arm attachment even though I've mentally modelled it a few times already. Thus, I decided to start thinking about the actual resin cartridges.

Volume

Part of the reason was to decide if I should reduce the thickness of the cartridges to gain another 50mm of Z height or prioritise more resin volume. The latter is divided over 5 cartridges so it'd probably gain more Z than lose in resin volume. As long as I can get the amount of resin that would correspond to 1kg of filament printing, I should be ok. I can always make a double high cartridge for the 2 most used materials if not printing in full 1-bit + alpha channel colour.

Shape

The cartridges are still intended to be relatively flat, house shaped containers that maximise the available area inside the outer case. Considering Matterhackers' resin bottles are 90mm in diameter, I'd likely still only be able to fit 5 different materials in the space provided. It'll just be harder to access them.

Motors

The resin is unlikely to perfectly laminate just by gravity alone, so a pump motor would be needed. There might be a solution that only requires 1 motor, but I don't have it. I believe that there would need to be one to move reclaimed resin into a buffer and another one to move it out of the buffer to be applied to the PET film.

Pump

Until proven not to work, I'm going to aim for a mostly 3D printed peristatic pump.

The cartridges are actually intended to be the permanent storage container of resin. While it means that I can't use a cool, see-through tube like a custom PC water loop (which would've helped with resin identification without labels or fancy LED's like Me In The Past envisioned right at the start of the project), it does mean that I intend to print new cartridges when there aren't any empty ones instead of pouring the resin back into the bottle and cleaning the cartridge out. The pump is also intended to be a seal so that resin doesn't escape when stored. I know that this sounds like the consumable ABS build plates I heard Stratasys uses for their older ABS printer, but the containers are printed and so are unlikely to last forever and the main motivation of this project is to make resin printers safer to use.

Where possible, I'd like to avoid screws, steel dowels and ball bearings in the design.

Due to the cartridge having a wall thickness, I think that the optimum solution to maximise resin volume is to have both pumps stacked ontop of each other. This could spur another appearance of the double stacked motor.

Applicator

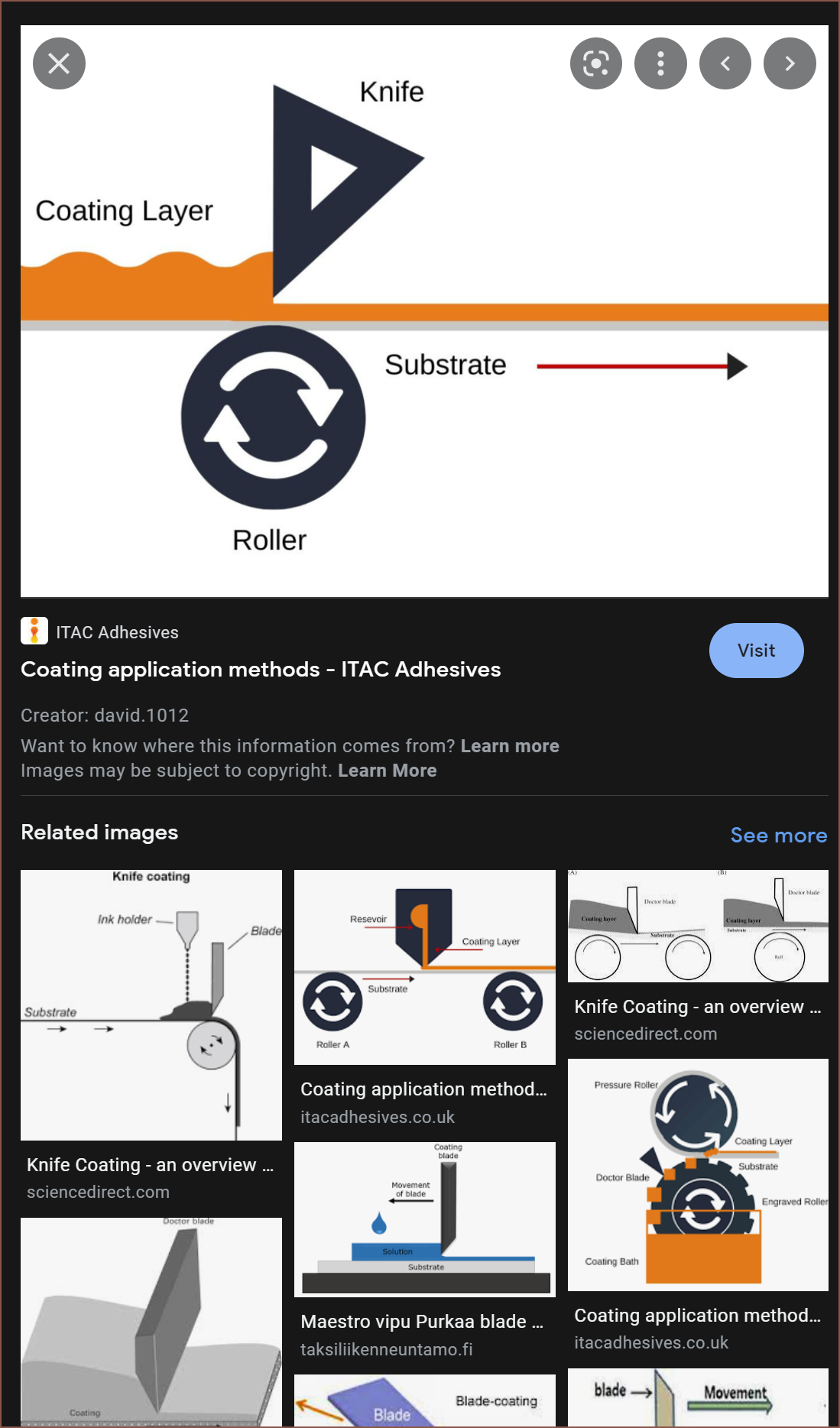

When I started the project, I knew that applying a material to a surface must've been a problem that has been solved decades ago. I've only now found a lead on Google.

Moments before seeing this, I was actually wondering if I could use the scraper used to reclaim the resin could also be used to set the height of the resin coating from the other side. The thought came from SLS recoaters.

Moments before seeing this, I was actually wondering if I could use the scraper used to reclaim the resin could also be used to set the height of the resin coating from the other side. The thought came from SLS recoaters. I haven't looked into it much, but the "resevoir" approach might require a greater amount of pump and manufacturing precision to perform and more likely to partially clog (as in, a void in the lamination). The blade allows me to apply a lamination without a roller as a moving part, and with lamination height set to 0 (or negative), I might be able to make a seal to scrape the material into the collection area.

Oh but I won't be able to suck back the resin still in the application zone due to the same seal. Would it be possible to skip the scrape reclaim alltogether and collect all the resin back in the application zone? No... I think it'd have to:

- scrape the resin from the PET film

- move the scraper away from the film a minute amount so that there isn't a seal and the application pump draws back in what resin it can

- apply any resin still in the application zone and scrape it off.

2 and 3 would only be needed for changing to a different resin. Also, when I'm talking about movement, it's actually the application roller that's moving towards and away from the scraper and not the other way around.

There would probably be something like the string used in the cleaning roller on the cartridge to catch any resin that makes it though all the main seals.

Lastly, the tubes for the reclaim section are likely to be on the far edges since it's more likely that nothing printed there and so would see the highest amounts of reclaimed resin.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.