I have always thought of FDM 3D printed parts as somewhat porous. As though defect holes in the wall of the part are inherit to the hobby level 3D printing process. I assumed that some kind of sealant would need to be applied to achieve any level of water ingress protection. Recent testing of the first OpenDendrometer enclosure prototype has shown that these assumptions are not true.

Now, I am only trying to develop a weatherproof 3D printed enclosure (some might call it water resistant); not a waterproof one. So the requirements are less challenging, but I still expected to encounter issues. Incidentally, I think I achieved a weatherproof 3D printed enclosure on the first iteration.

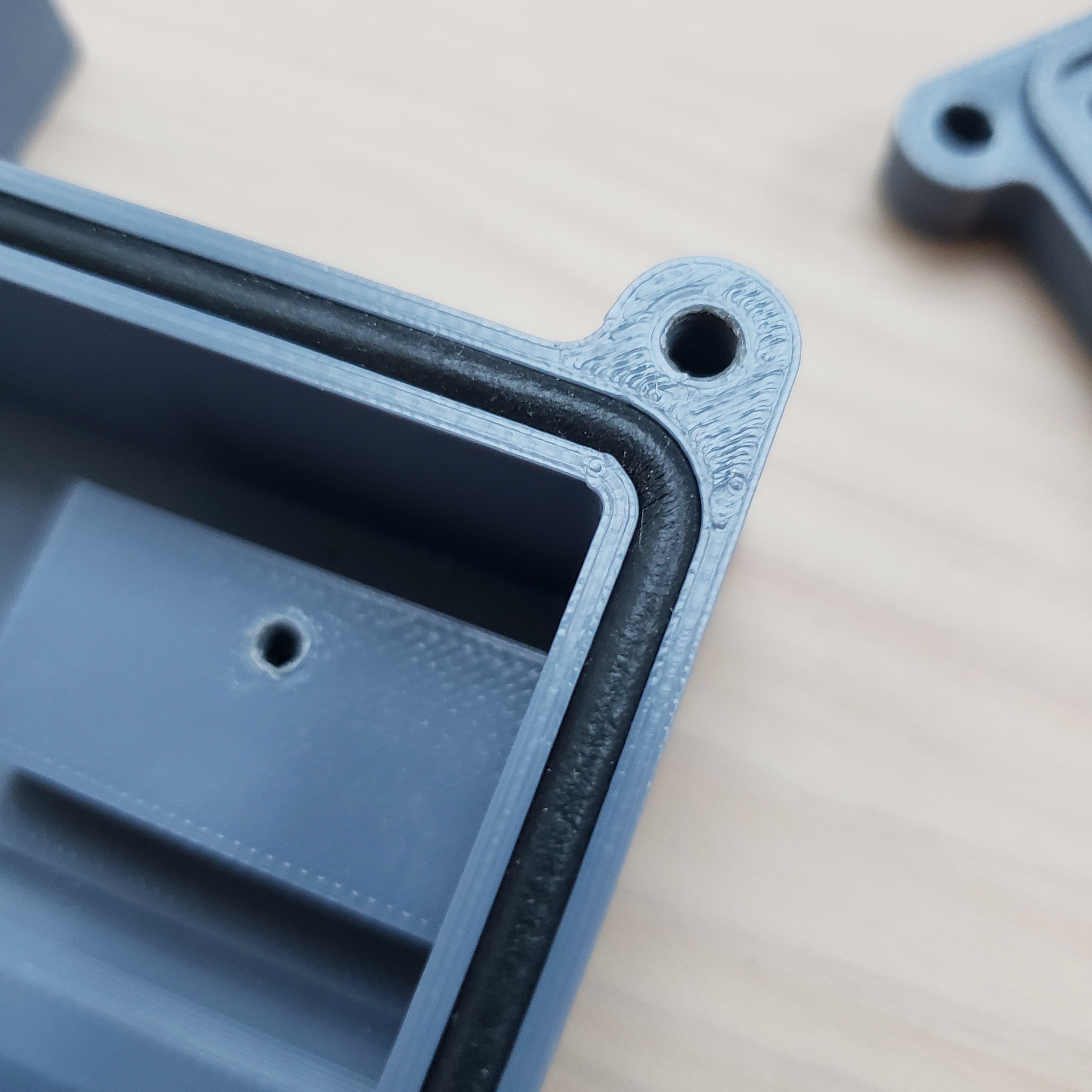

Really all I did was to copy the foam cord water seal strategy used on almost all small ingress protection rated electronic enclosures. It involves a foam cord gasket between the case and the cover. With all fasteners between case and cover on the outside of the gasket seal and features in each to either capture or compress the foam cord.

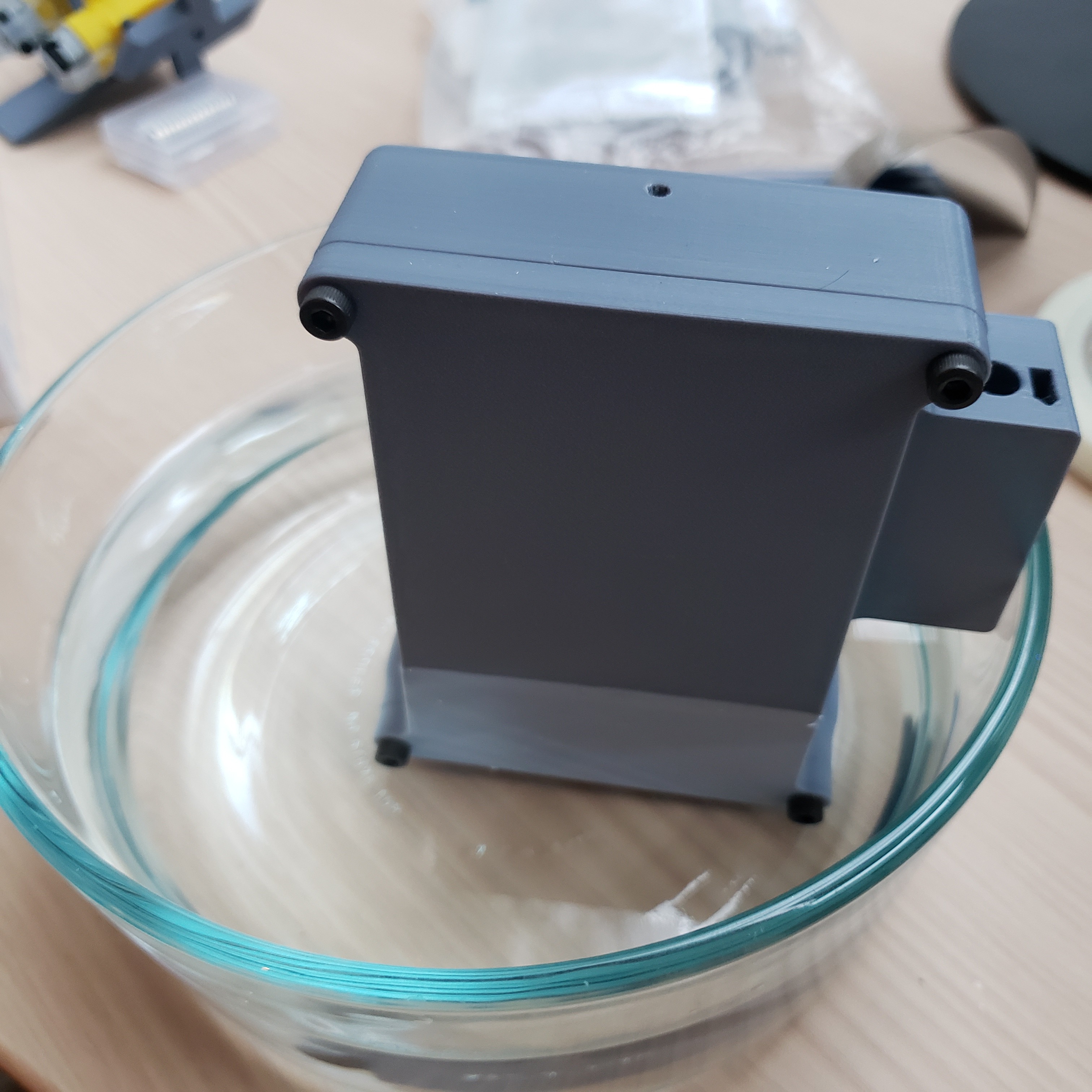

To test the seal, I put a piece of tissue paper inside and placed it in a bowl of water. After five minutes in the bowl of water -> voila, the tissue paper was still dry.

To test the seal, I put a piece of tissue paper inside and placed it in a bowl of water. After five minutes in the bowl of water -> voila, the tissue paper was still dry.

Even without applying any sealants to the 3D printed parts, it achieved a 5 minute waterproof seal. Which should be more than enough for just a weatherproof enclosure that will only see occasional precipitation.

I suspect that UV exposure may damage the plastic enough overtime to cause water ingress, but all testing is going to be fairly short at less than a month. I will worry about how to combat long term UV exposure once the design passes system level testing.

John Opsahl

John Opsahl

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.