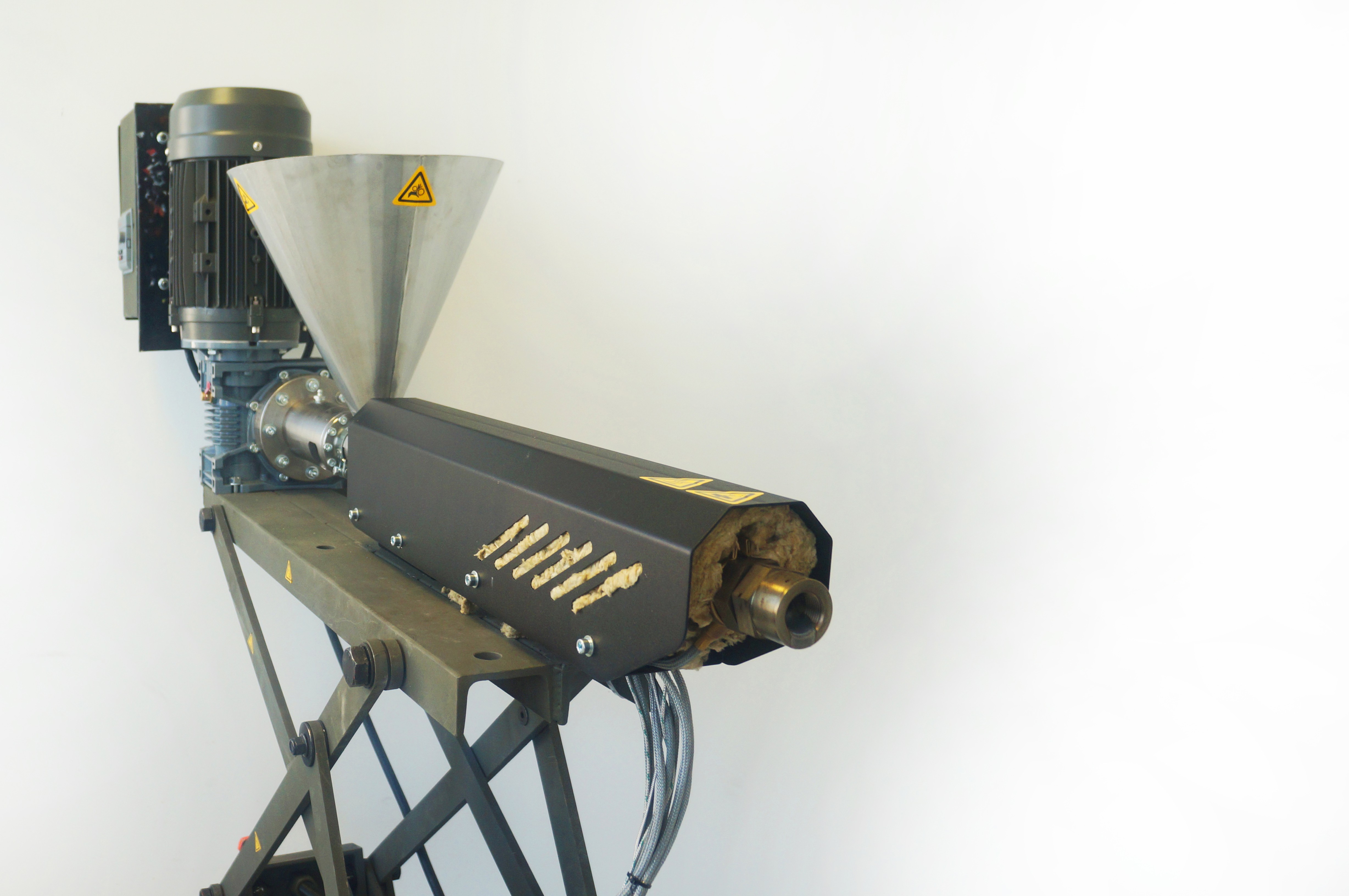

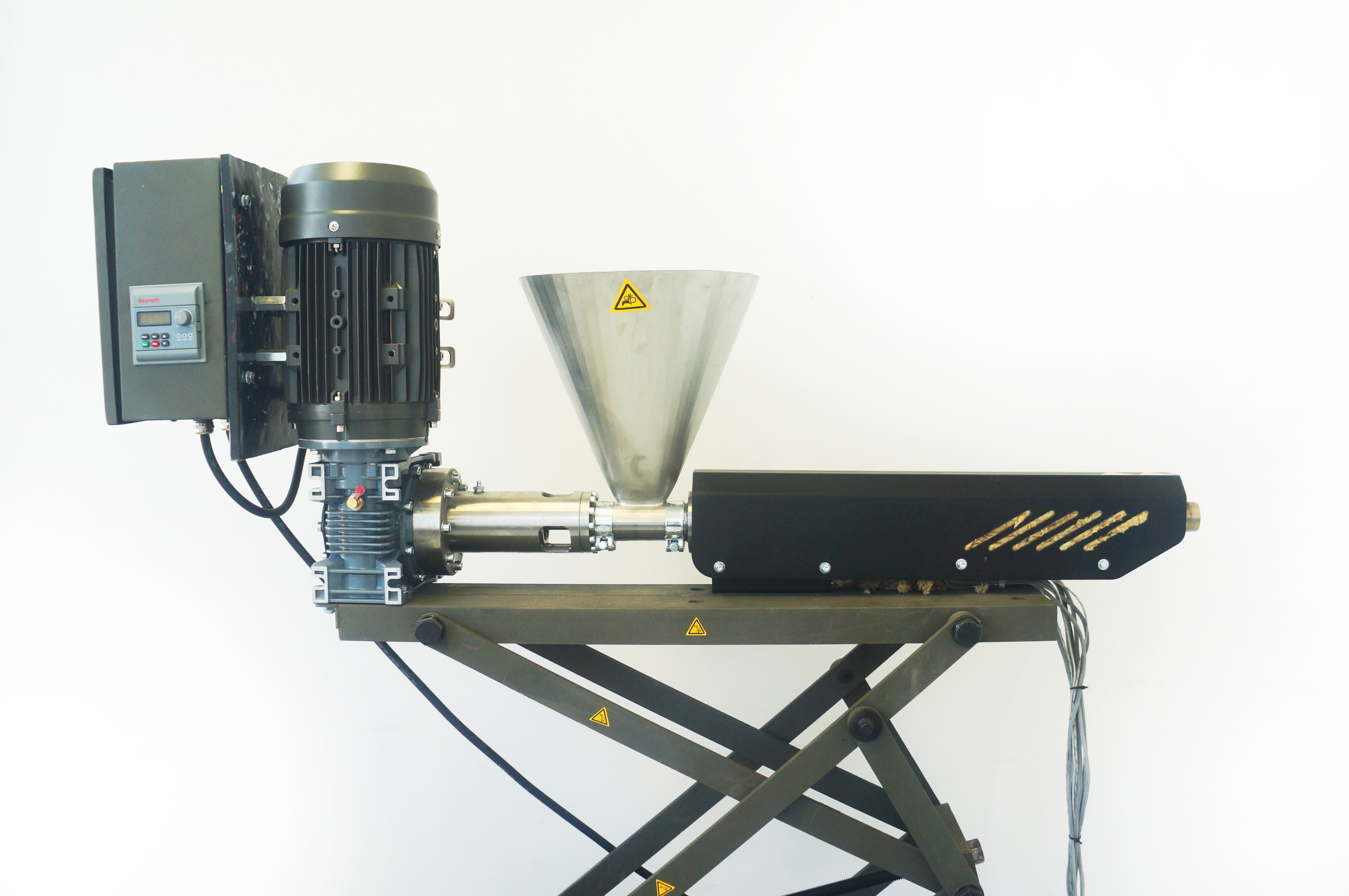

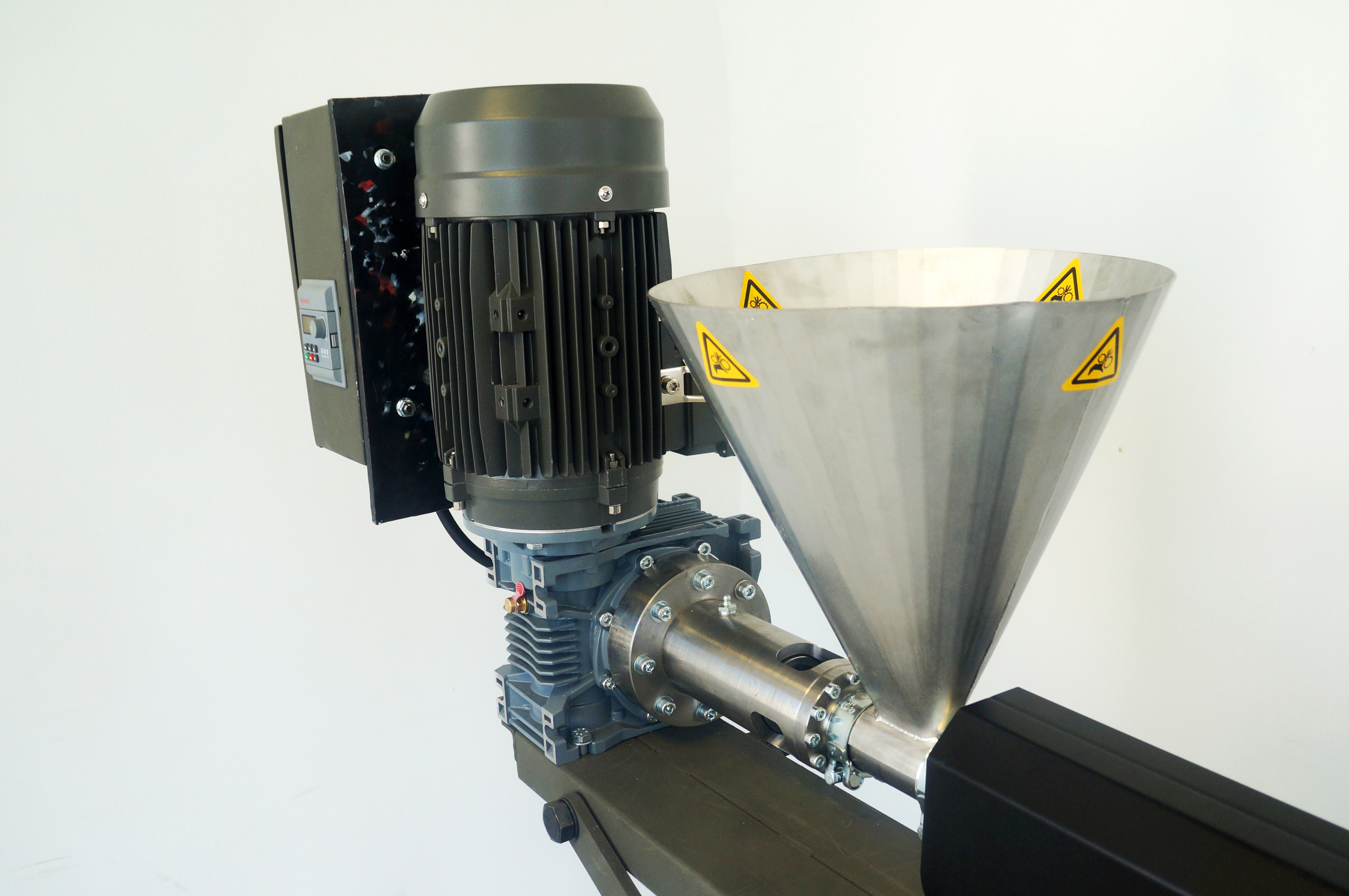

To make recycled plastic skateboard decks, you need an extrusion machine. It melts the plastic into a liquid and fills the mould by pushing the molten plastic out of a barrel using a motorized screw.

There are many variations of the extrusion machine out there but none were perfect for our needs, so we set out to design one that fits, as a set, with out mould, to complete the production system. What differentiates ours is that it has an adjustable height, wheels, and lean profile (700mm wide) making it practical for events, demonstrations or simply moving around the workshop. The adjustable height allows it to be used for a broader range of applications that require a low or high profile, or for interactions that involve children and shorter people.

Like all our work, this machine is fully open source and online now, you can find the download kit 📦 HERE 📦

This kit includes all the information you need to build your own extruder.

The extruder features an extrusion barrel designed by Ateliers des recycleurs fous. It is from their model “C4-PO”. More information, such as how to build it, can be found here:

atelierdesrecycleursfous.fr/extrudeuse

Special kitos (Thanks) to Caracara Collective for the many kinds of support given during this phase of the build.

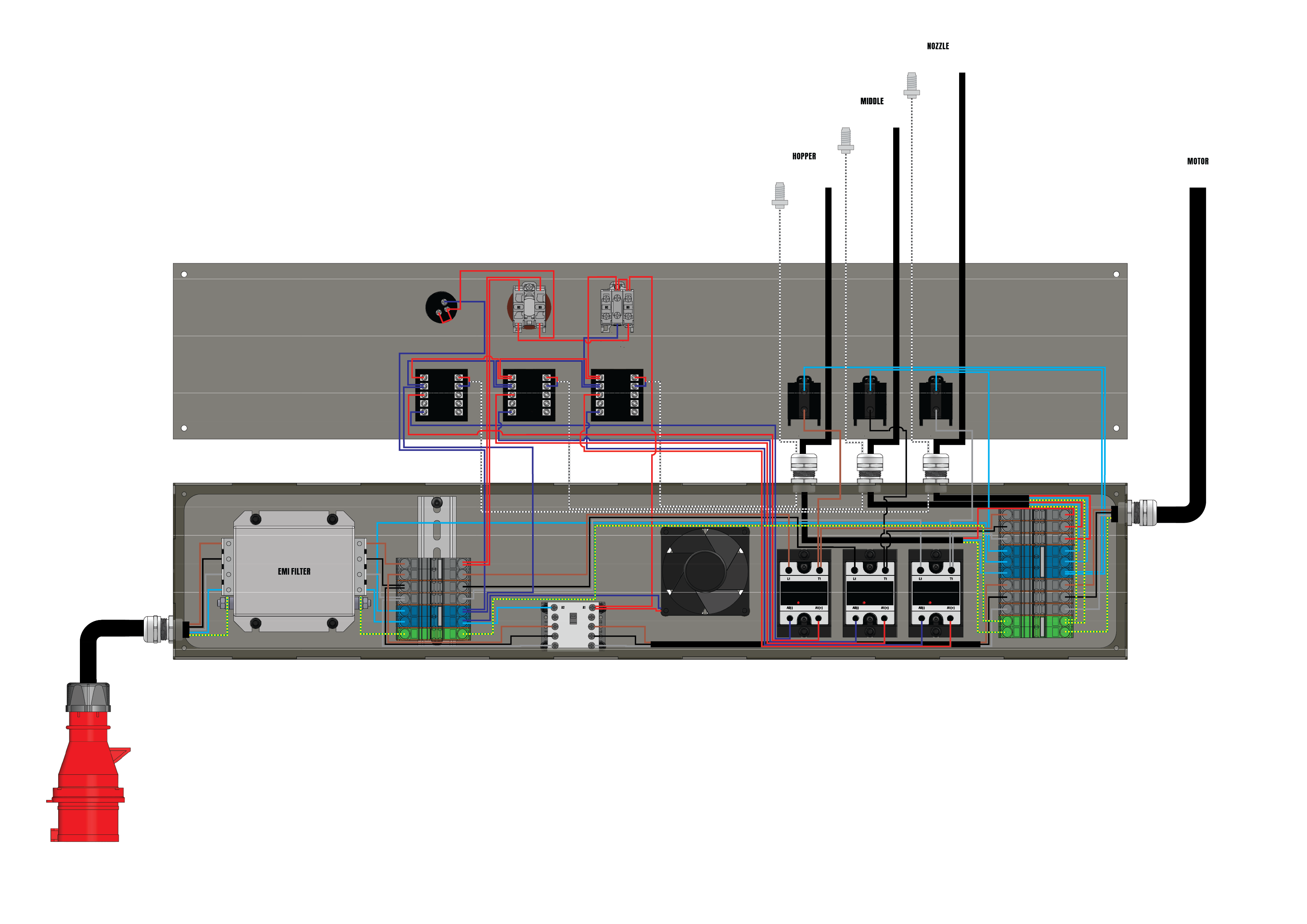

Electronics Schematic

RPSD-EXT Technical Data

General | |

Model | RPSD-EXT |

Version | 1.0 |

Type | Extrusion |

Year | 2022 |

Dimensions (length x width x height) | 1400 x 700 x 500 min 1400 max |

Mass | 200 kg |

Total Power | 5 kw |

Total Amps | 12 A |

Heating | |

Power supply | Three-phase electric - 380V |

Heating element type | Band Heater / Collar |

Number of heating elements | 6 |

Heating power | 2 kW |

Operating temperature | 0 to 250 °C |

Motor | |

KW | 3.3 kw |

Amps | 137 Nm |

RPM | 187 |

User Process | |

Materials processed | Soft plastic, Hard plastic |

Filling Method | Extrusion |

Construction | |

Construction materials | Steel Frame |

Material Cost (EU) | 7500 Euro |

Manufacturing time | ± 5 Days |

Workforce | 1 Person |

Difficulty | ★ ★ ★ ☆ ☆ |

Connections | |

Electrical | Three phase plug socket 16 A |

Pneumatic | Compressed air for cleaning |

Jason Knight

Jason Knight

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.