First of all, we began to solve the problem with dry contact.

After uECG, and in general researching the market for EMG sensors, I wanted to avoid using disposable electrodes. In addition to being environmentally friendly and economical, disposable electrodes are not a practical solution, every time you use the device you need new ones and if they suddenly run out, then you simply cannot do things.

But what's the way out? The first thing we thought about was practicality. It was necessary to find a solution that would not use soldering, preferably a removable design. Detachable structure...

Having a construction background, I got the idea that it could be some kind of bolt! Googling the existing options, I found what is called a connecting or belt bolt, or a binding screw. These bolts are used in construction, textile fittings and stationery. Despite the prevalence, a 2-3 mm high bolt was not so easy to find. After checking several dozen online stores, I was able to find belt screws with a height of 5 mm (and available in single quantity, which was not that easy to find!)

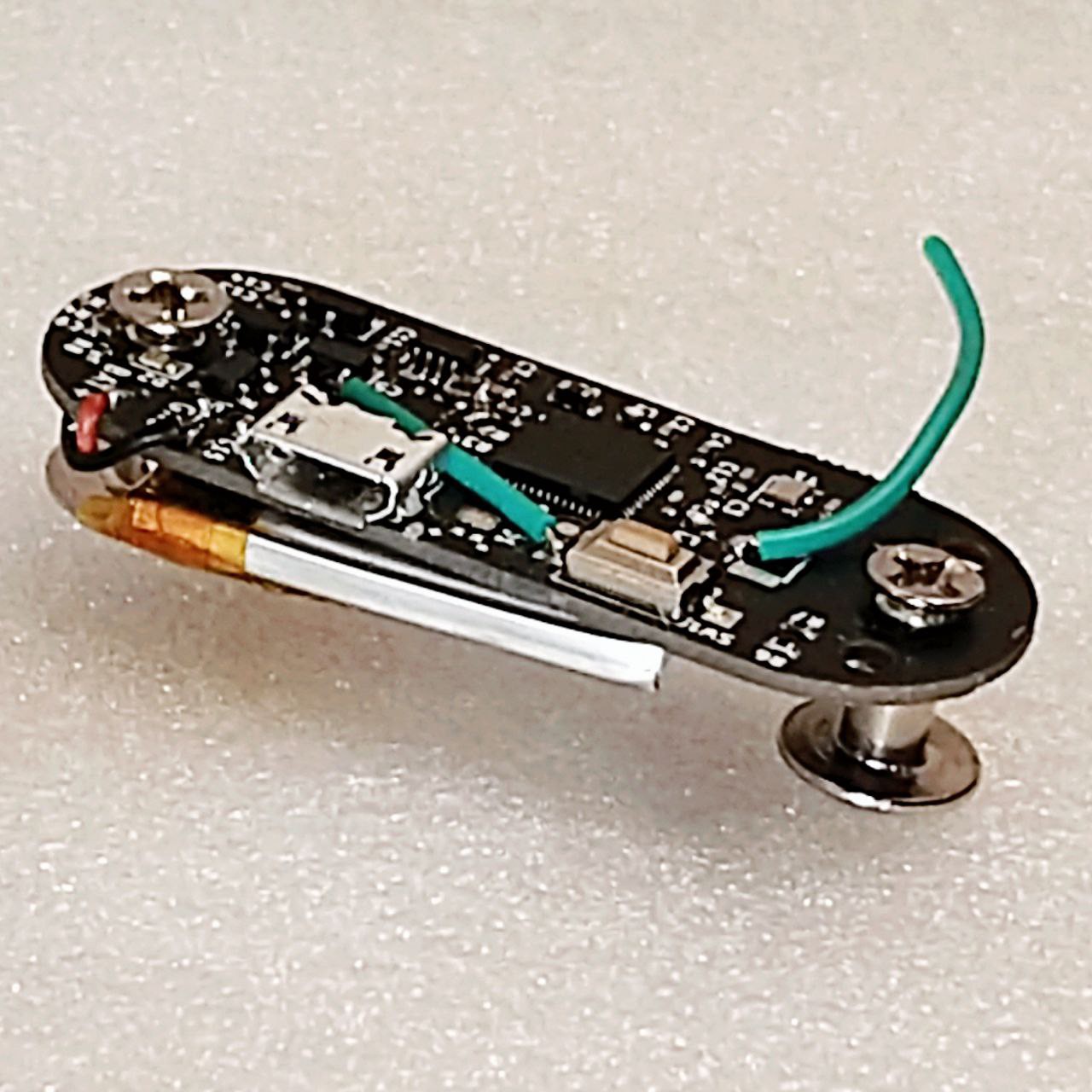

But this was only half the solution - which provided a smooth surface with a diameter of 8 mm for picking up the EMG signal. The design of the board was very compact with only 5mm of room on the side of the components. Therefore, we decided to replace the bolt component with ordinary screws, slightly longer to compensate for the height of the board. And what came of it?

Testing showed a fairly good signal, plus the height of the belt bolt made it possible to level out skin changes during muscle contraction (as disposable electrodes do).

Here is a simple solution to a difficult problem. The next task was to attach the device to the arm.

Ultimate Robotics

Ultimate Robotics

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.