I tried my first saw cuts today. I used a circular saw with no track guide, not a setup I intend to use "in production," but I still hoped it would teach me something.

It did!

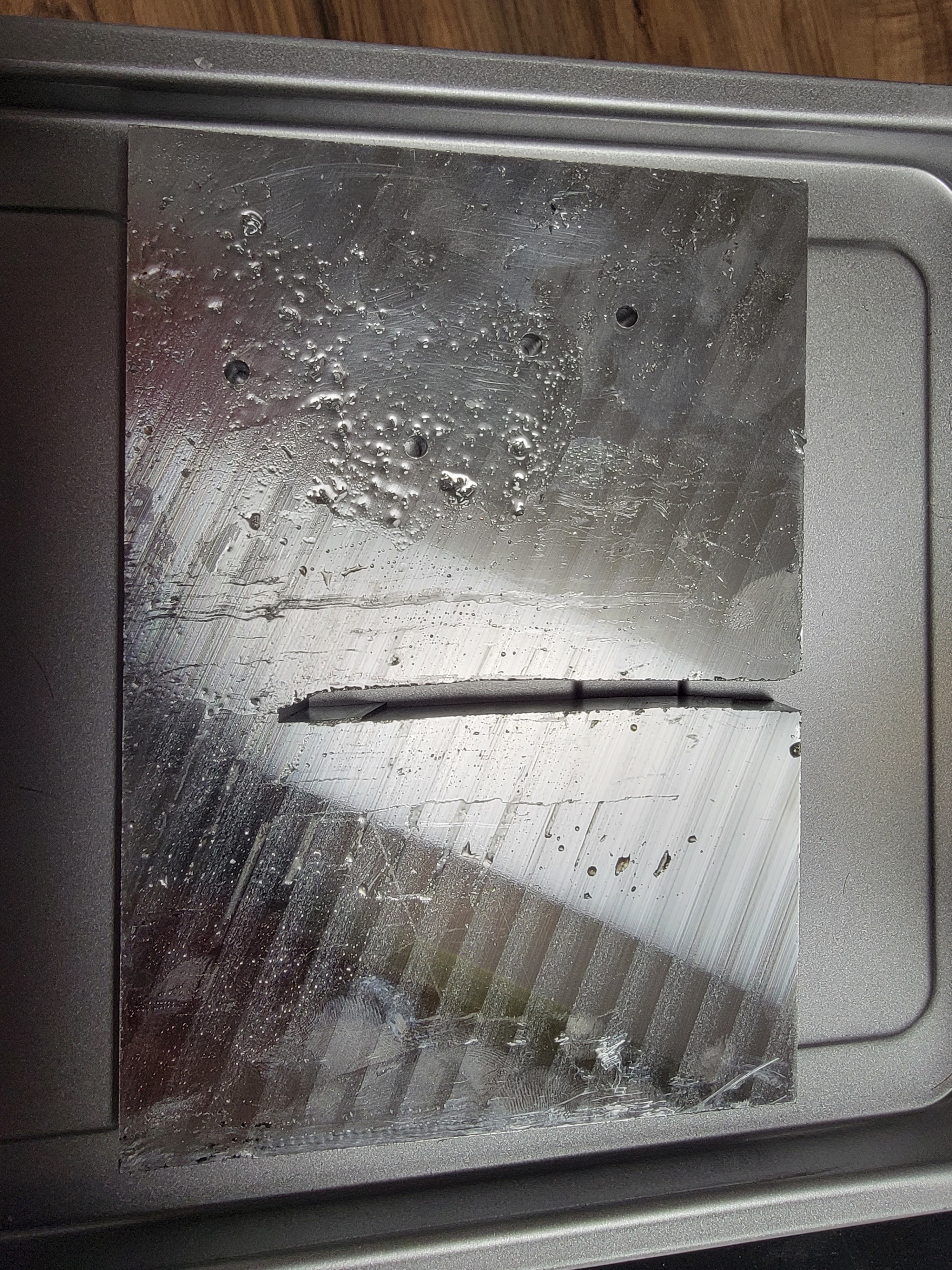

Lesson one: A saw guide is absolutely necessary. The channel is so wide and uneven because I didn't have one.

Lesson two: I almost definitely need cutting fluid for this part. It removes material much more quickly than the drill press. The blade is also more expensive, so longevity matters more.

Lesson three: The chips that come off the cut are hot enough to be uncomfortable. This may get better with cutting fluid.

Lesson four: Cutting with a saw isn't as loud as I expected, either. Probably won't even consider doing this work at night, but I can do it during the day without fear of being chased out of the neighborhood with pitchforks.

Lesson five: I put together a seriously janky jig for this cut because I'm prone to trying to perfect everything before I do any action. This is a thing worth working on. The jig was nowhere near adequate.

I can't really take any more lessons without improving my technique. I THINK the kerf is probably going to be larger than expected, but without a clean cut, I don't know how much is due to the wandering blade. The cut also felt less comfortable on my body to do, but that's almost definitely down to an appropriate jig.

Next step is probably a better job and one more small test piece. Maybe one large enough to make a 120mm^2 piece so I can attempt a real output.

Daniel Grace

Daniel Grace

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.