So my 2" dual locking casters came in. I have very mixed feelings on them. They are significantly smaller and I think they would work well for a medium loaded cart. As a quick test I swapped them out with my 3" casters that I had been using under my drill press and it seemed to hold up ok and roll just fine. Not quite as nice as the 3" but good enough.

However on the flip side these are made a lot cheaper than the 3" casters and I find it hard to believe they could hold 600 pounds. I think I will keep them for smaller carts and leave the larger casters for the benches.

One thing I did not think about with these smaller casters is that you really need to use screws and not bolts. There is only about 1/4" of room between the end of the brake release and the base of the caster when the brake is engaged. It is easy to get the release hung up on a bolt. There were several reviews online complaining that the brake was sticky, I suspect this was the real culprit.

Another thing about casters in general that I did not think about is that the brake lever must have some clearance around it so you can get your foot in on top and underneath it. This means no hiding the casters under the cart, they must stick out at least the width of the brake lever. And with these smaller casters it is tricky to get your foot under the lever, but fortunately it does not take much force to release.

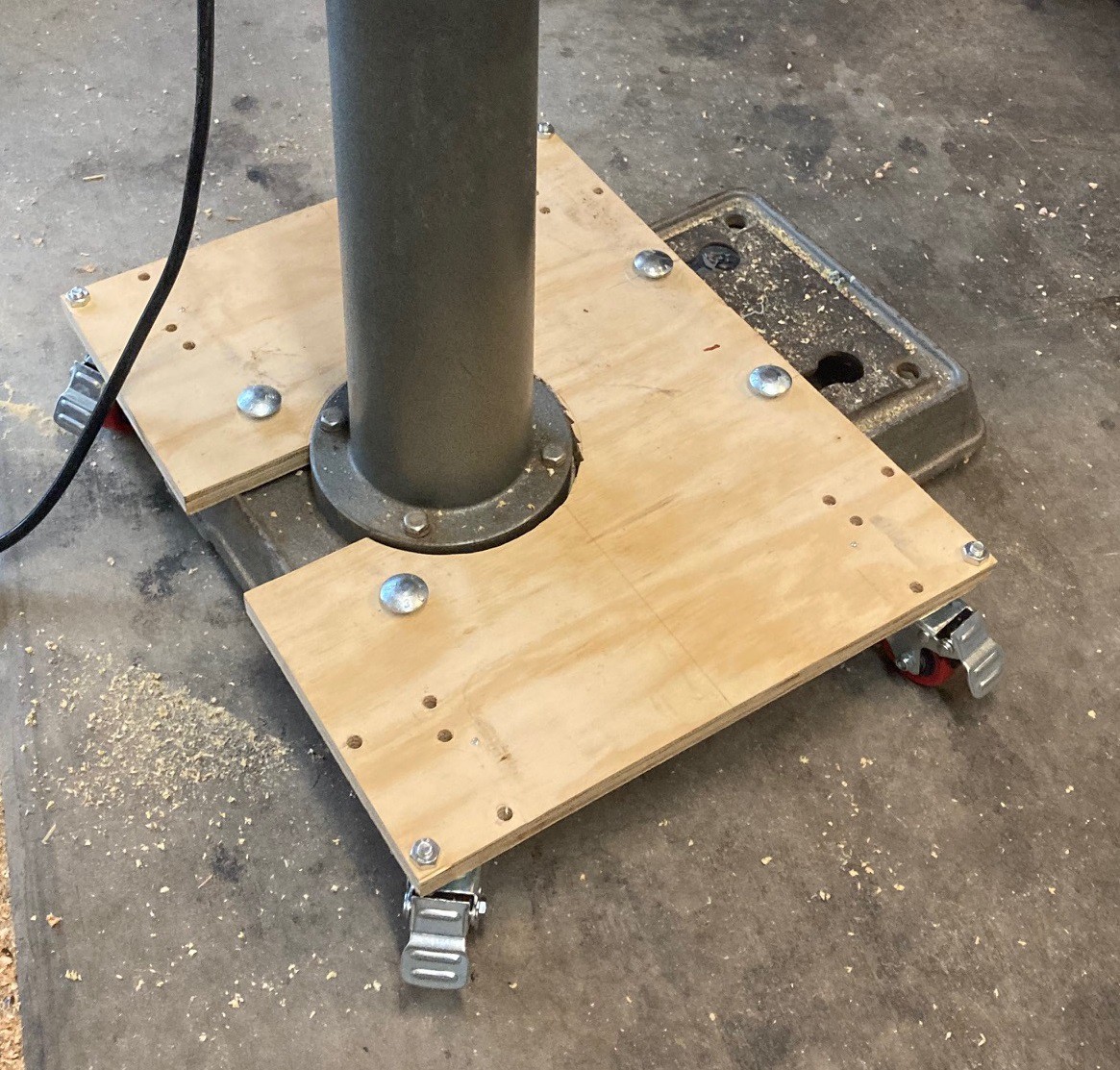

I really don't like having my drill press up high and I wanted to see if there was a way to keep it down low by hanging the base from a platform rather than resting it on top of one. So as another quick experiment I cut a notch out of my scrap board so I could slip it over the post and used the 2" casters to roll it around on. This works, but not well. I would not be comfortable leaving it permanently like this. There is a noticeable amount of bow in the 5/8" plywood and I can easily rock the top of the drill back and forth and watch the board flex. On the upside the whole thing sits nice and low and it feels more planted on the ground and less likely to tip over.

I may come back to this idea later and build some sort of a base that envelopes the pedestal and provides some rigidity. Unfortunately they were not thinking about mobile carts when designing this pedestal and there is no way to run a 2x4 (or any other lumber) straight across the rear mounting holes on the base without notching out a significant amount of wood.

It is not a success but not a total failure, I will keep thinking on this. Raising the drill press by 4" may not be the end of the world, maybe I should just let it go.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.